High-performance Cu2Se block thermoelectric material with nanopore structure and rapid preparation method of high-performance Cu2Se block thermoelectric material

A technology of nanoporous structure and thermoelectric material, which is applied in the direction of thermoelectric device node lead-out material, thermoelectric device manufacturing/processing, binary selenium/tellurium compound, etc. The problem of grain growth is easy to achieve the effect of short preparation time, reduced thermal conductivity and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

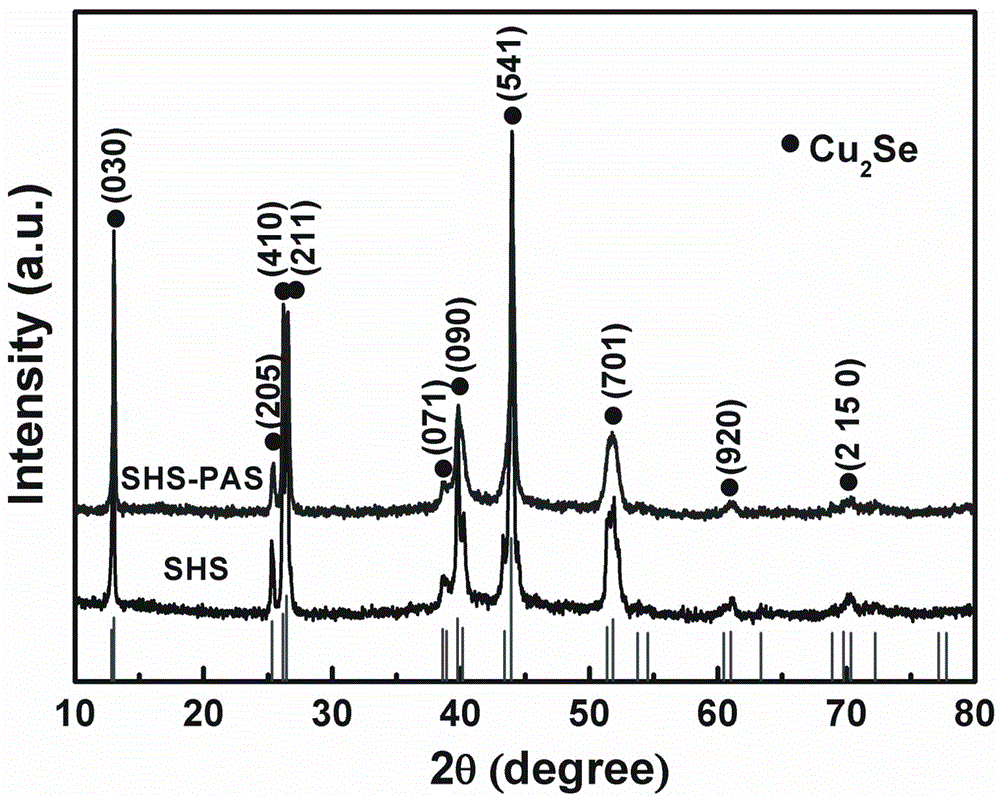

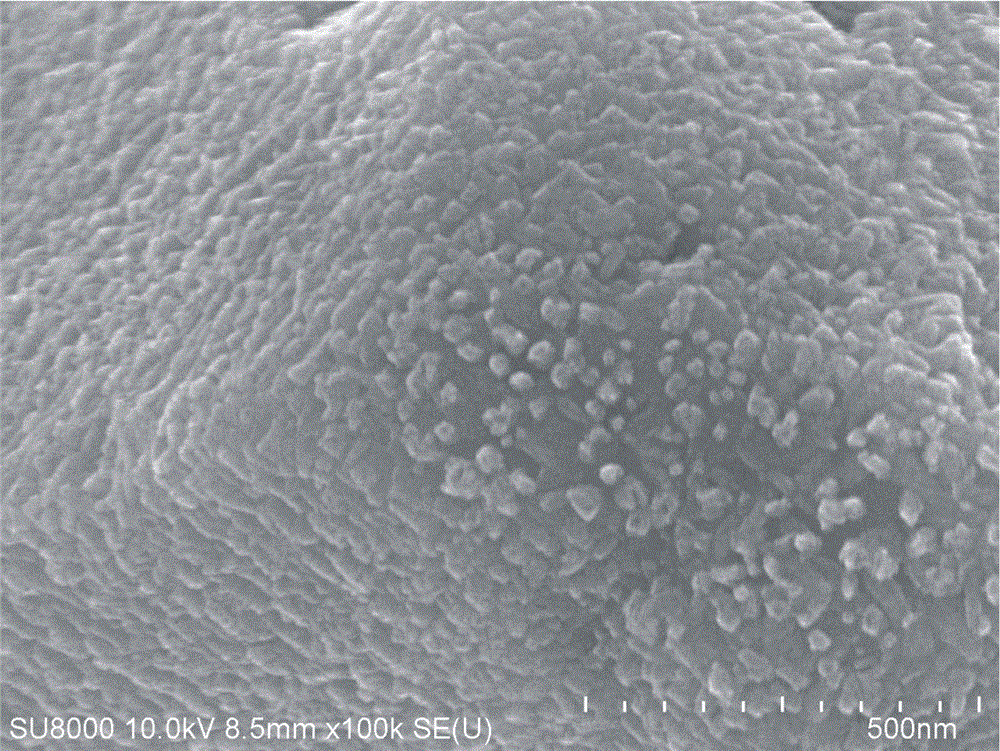

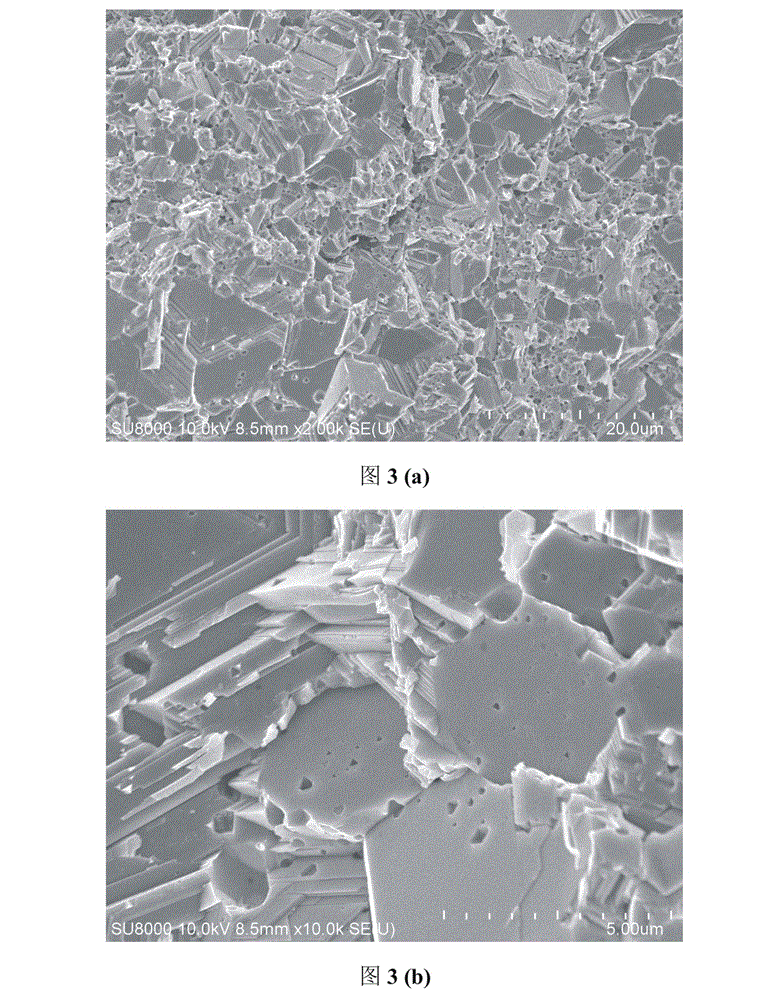

[0049] A high-performance Cu with nanoporous structure 2 The rapid preparation method of Se thermoelectric material is characterized in that it comprises the following steps:

[0050] 1) With Cu powder, Se powder is raw material, weighs that the mol ratio of Cu powder and Se powder is 2:1, and weighing total amount is 15g, and raw material is mixed uniformly in agate mortar, obtains mixed powder as Reactant, reactant is put into steel mould, adopts the pressure of 10 MPa to be 12 mm cylindrical blocks in diameter on tablet press;

[0051] 2) Vacuum-seal the reactant in a quartz glass tube (the inner diameter of the quartz glass tube is 17 mm, the outer diameter is 20 mm), and heat the bottom end of the quartz glass tube on a heat source at 300°C until the self-propagating reaction is initiated and stopped Heating, the reaction spreads from the bottom to the top in the form of combustion waves, and naturally cools down after the completion of the self-propagating reaction to o...

Embodiment 2

[0062] The same process as in Example 1 was adopted, except that the sintering temperature was 500 °C, the sintering pressure was 50 MPa, the heating rate was 50 K / min, and the holding time was 3 min.

[0063] Table 2 The nominal composition and actual composition of EPMA of the SHS product and the product sintered by PAS in Example 2

[0064] sample nominal composition The actual composition of EPMA SHS product Cu 2 Se Cu 2.004 Se Product after PAS sintering Cu 2 Se Cu 2.02 Se

Embodiment 3

[0066] The same process as in Example 1 was adopted, except that the sintering temperature was 600 °C, the sintering pressure was 30 MPa, the heating rate was 100 K / min, and the holding time was 5 min.

[0067] Table 3 The nominal composition and the actual composition of EPMA of the SHS product and the product sintered by PAS in Example 3

[0068] sample nominal composition The actual composition of EPMA SHS product Cu 2 Se Cu 2.004 Se Product after PAS sintering Cu 2 Se Cu 2.06 Se

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com