Chlorine dioxide gas generating agent pack, and manufacturing method and storage method thereof

一种气体产生剂、二氧化氯的技术,应用在二氧化氯、氧化氯、杀生剂等方向,能够解决味道残留及腐蚀、危害、粪便及尿液除臭效果不理想等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

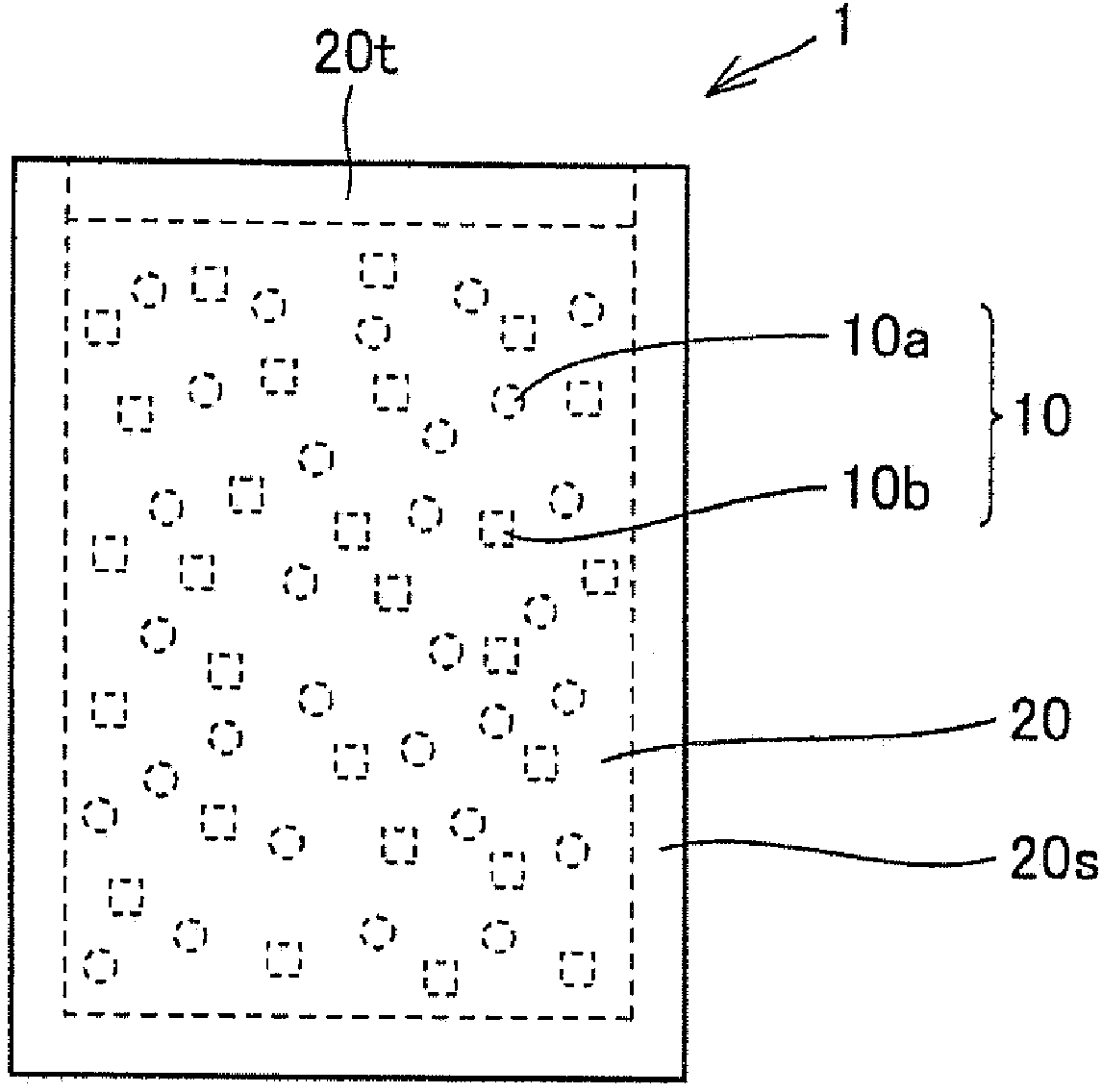

[0024] refer to figure 1 , a chlorine dioxide gas generating agent package 1 belonging to an embodiment of the present invention includes: a chlorine dioxide gas generating agent 10 comprising chlorite powder, gas generation regulator powder, hygroscopic agent powder, and water absorbent resin powder and a mixture of activator powder; and a gas-permeable film container 20, which is used to accommodate the chlorine dioxide gas generating agent 10, and can pass through water vapor and chlorine dioxide gas. Regarding the chlorine dioxide gas generating agent package 1 of the present embodiment, since the chlorine dioxide gas generating agent 10 is housed (specifically, sealed and housed) in a gas-permeable film container 20 permeable to water vapor and chlorine dioxide gas Therefore, the water vapor (humidity) in the air is in contact with the chlorine dioxide gas generating agent 10 through the gas-permeable film container 20, so that the chlorite powder and the activator powde...

Embodiment approach 2

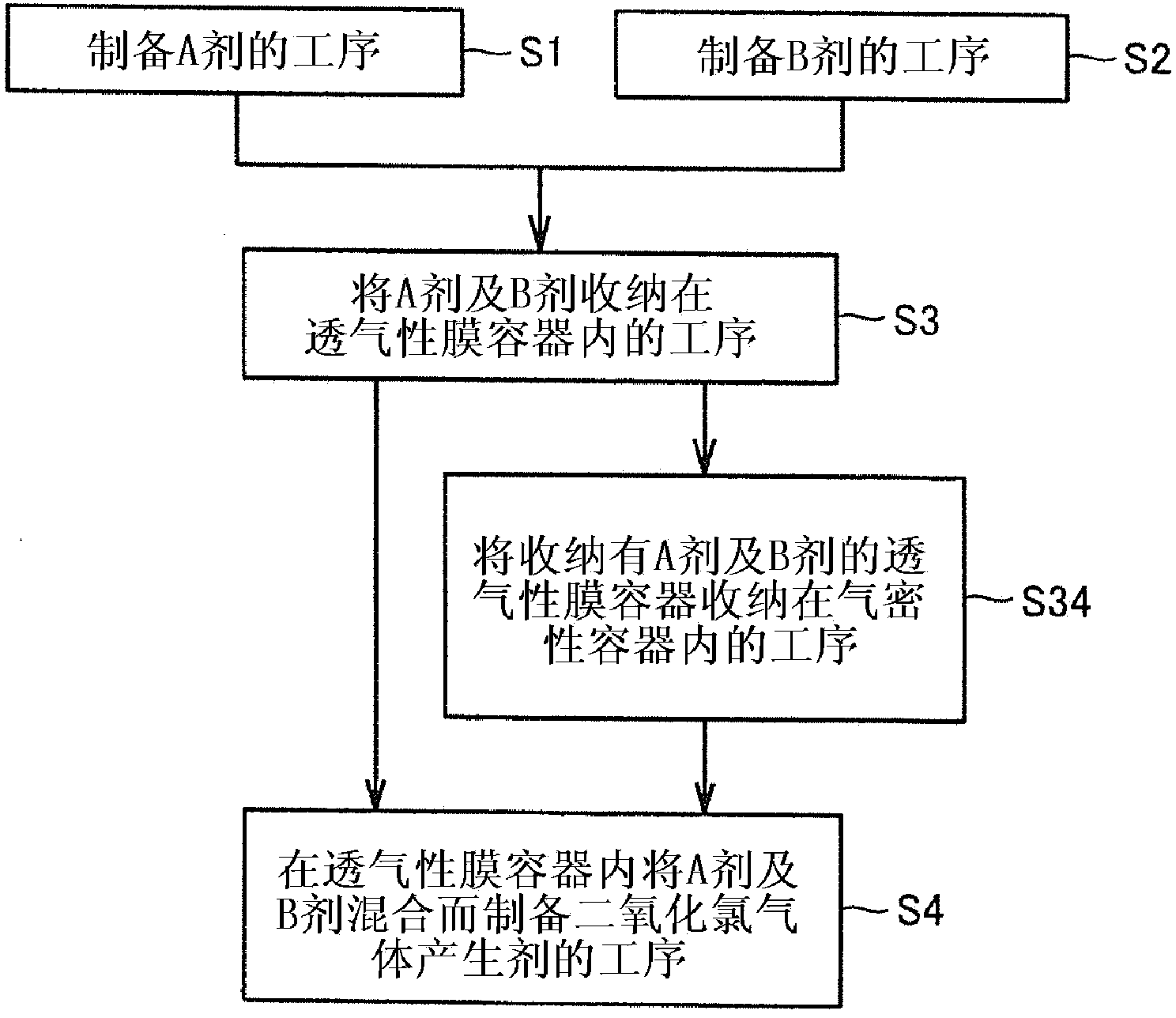

[0050] refer to figure 1 and figure 2 , as another embodiment of the present invention, the manufacturing method of chlorine dioxide gas generating agent packaging includes: mixing chlorite powder and gas generation regulator powder to prepare A agent 10a step S1; mixing hygroscopic agent powder, water absorbent The process S2 of mixing resin powder and activator powder to prepare B agent 10b; the process S3 of accommodating A agent 10a and B agent 10b in a gas-permeable film container 20 that can pass water vapor and chlorine dioxide gas; The step of preparing the chlorine dioxide gas generating agent 10 by mixing the A agent 10a and the B agent 10b in the membrane container 20 . In the method for producing a chlorine dioxide gas generating agent according to this embodiment, agent A 10a containing chlorite powder and agent B 10b containing activator powder are respectively prepared, and agent A 10a and agent B are placed in a gas-permeable film container 20. 10b is mixed...

Embodiment approach 3

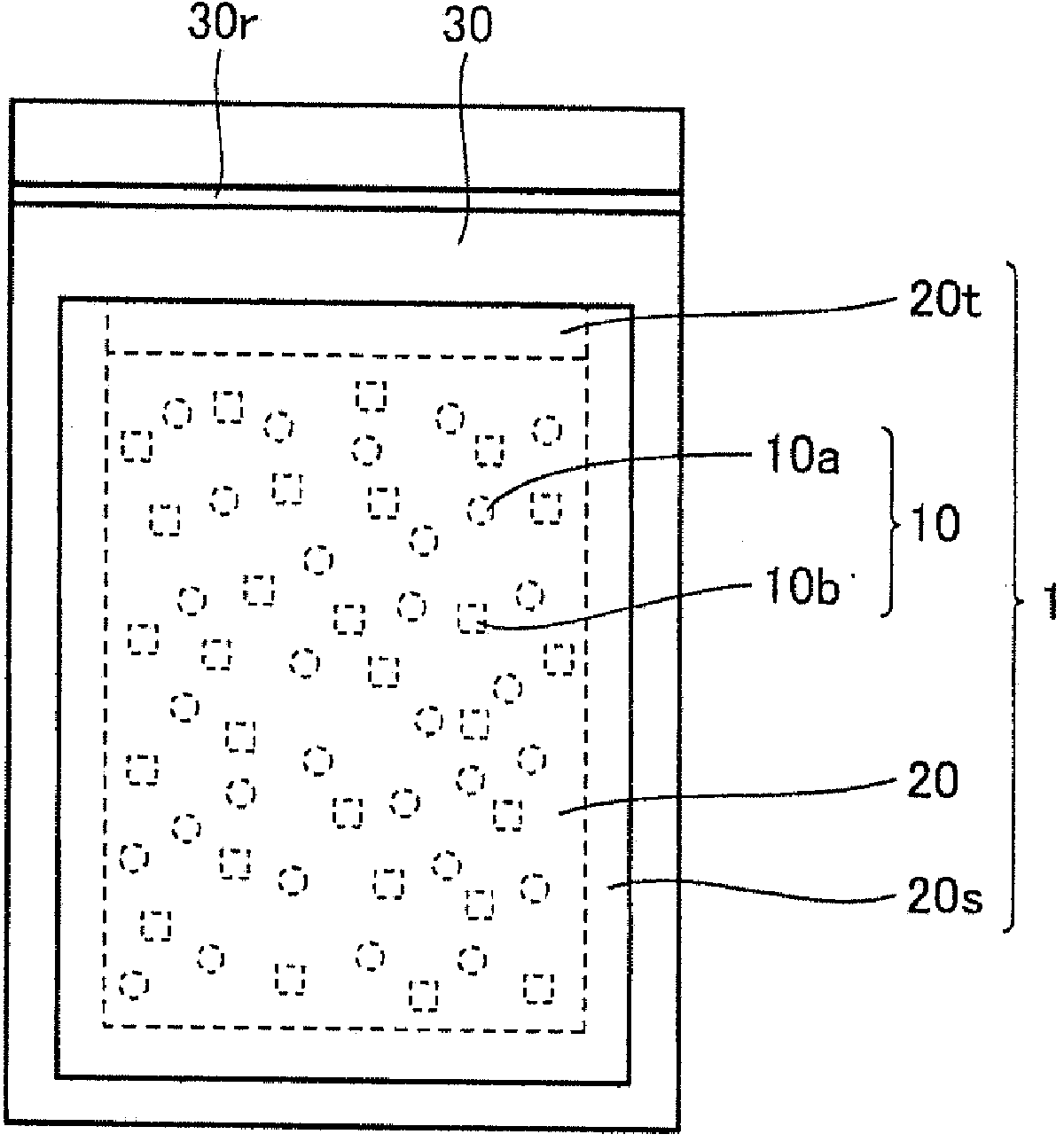

[0072] refer to image 3 , The storage method of the chlorine dioxide gas generating agent package belonging to still another embodiment of the present invention is a method of storing the chlorine dioxide gas generating agent package 1 of the first embodiment in the airtight container 30 . The preservation method of the chlorine dioxide gas generating agent packaging of the present embodiment can store the chlorine dioxide gas generating agent packaging 1 in the airtight container 30, preferably in an environment with a relative humidity of 35% or less in the airtight container 30. Therefore, the chlorine dioxide gas generating ability can be maintained regardless of the length of time from a short time of several hours to a long time of several years after the production of the chlorine dioxide gas generating agent package and before use.

[0073] In the storage method of the chlorine dioxide gas generating agent package of this embodiment, it is preferable to make the insid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com