Direct current tractive power supply system based on flexible direct current power transmission

A flexible DC transmission and DC traction technology, applied in electric traction, DC circuits can reduce harmonics/ripples, electric vehicles, etc., can solve the problem of rectifier units increasing the complexity of traction substations and affecting the reliability of DC traction power supply systems It is difficult to further increase the traction network voltage and other problems, so as to achieve the effects of small ripple, lower harmonic content, and reduced voltage and power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

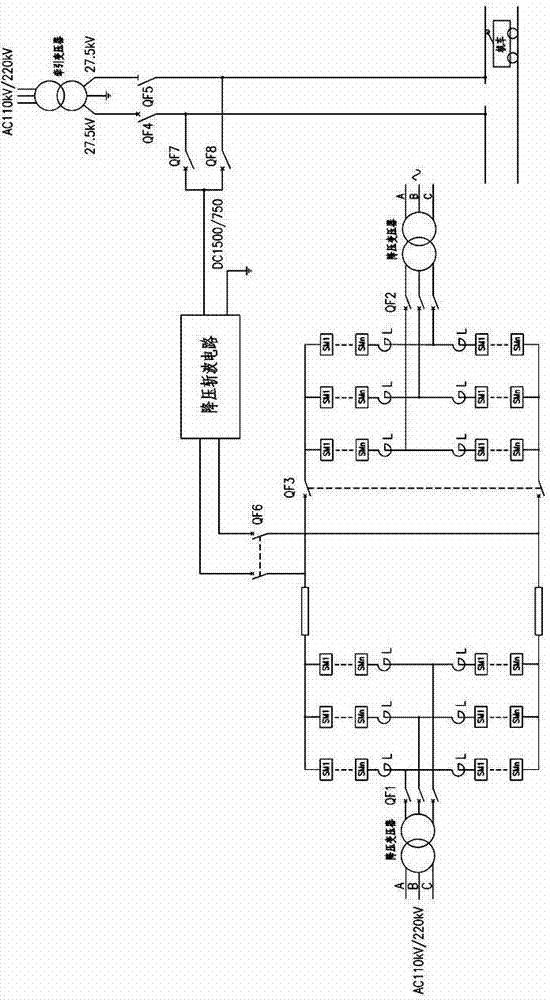

[0019] Such as figure 1 As shown, a DC traction power supply system based on flexible DC transmission of the present invention includes a step-down transformer, a double-terminal active high-voltage DC transmission system and a step-down chopper circuit. The double-ended active HVDC power transmission system includes two fully symmetrical converters, each of which is connected to the three-phase AC through a step-down transformer; the input end of the step-down chopper circuit is connected to the double-ended active The source is connected to the DC side of the high-voltage direct current transmission system, and the output end is connected to the traction system through the second switch assembly; the second switch assembly is interlocked with the third switch assembly.

[0020] see figure 1 , the first switch component is QF6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com