Hook-type commutator product, technology and mould

A commutator and hook type technology, applied in the field of commutator products, can solve the problems of not leaving two upper hook foot spaces, high manufacturing cost, low manufacturing efficiency, etc., and achieve the effect of improving manufacturing efficiency and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

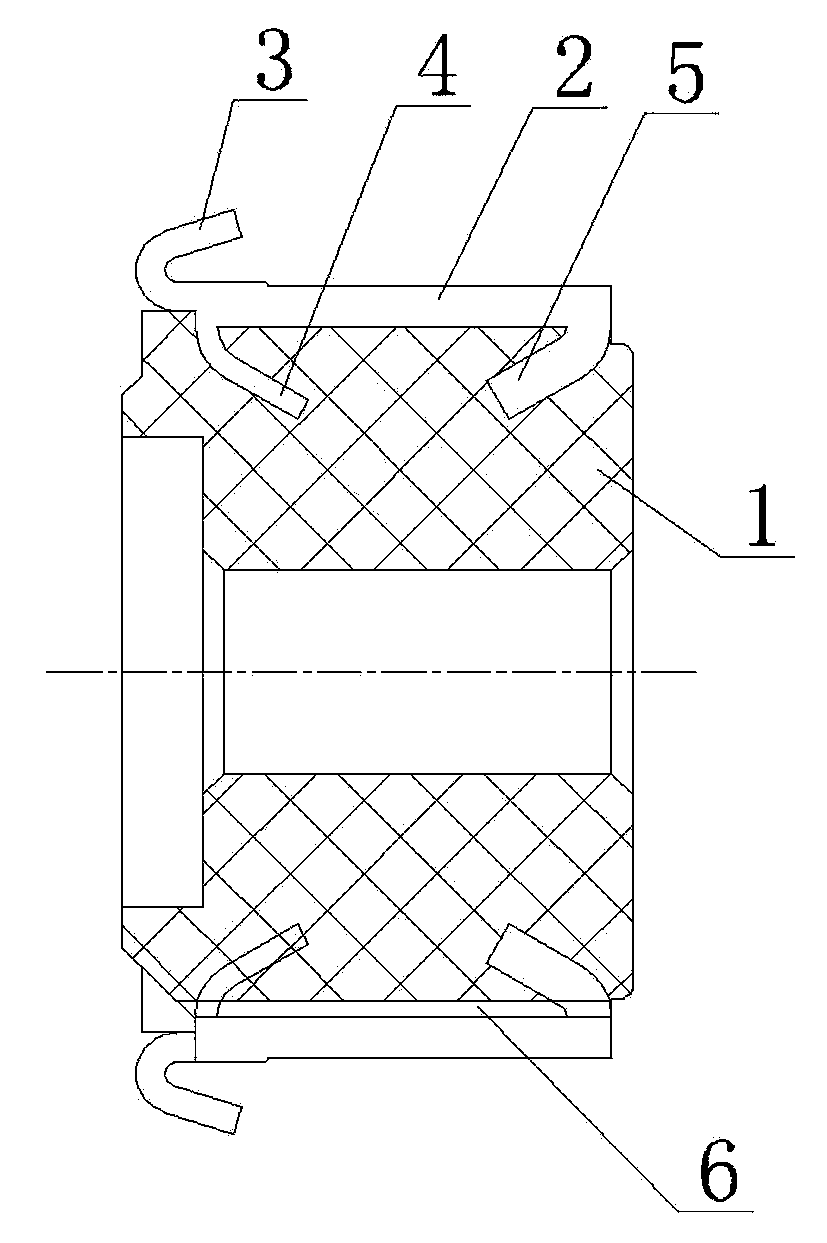

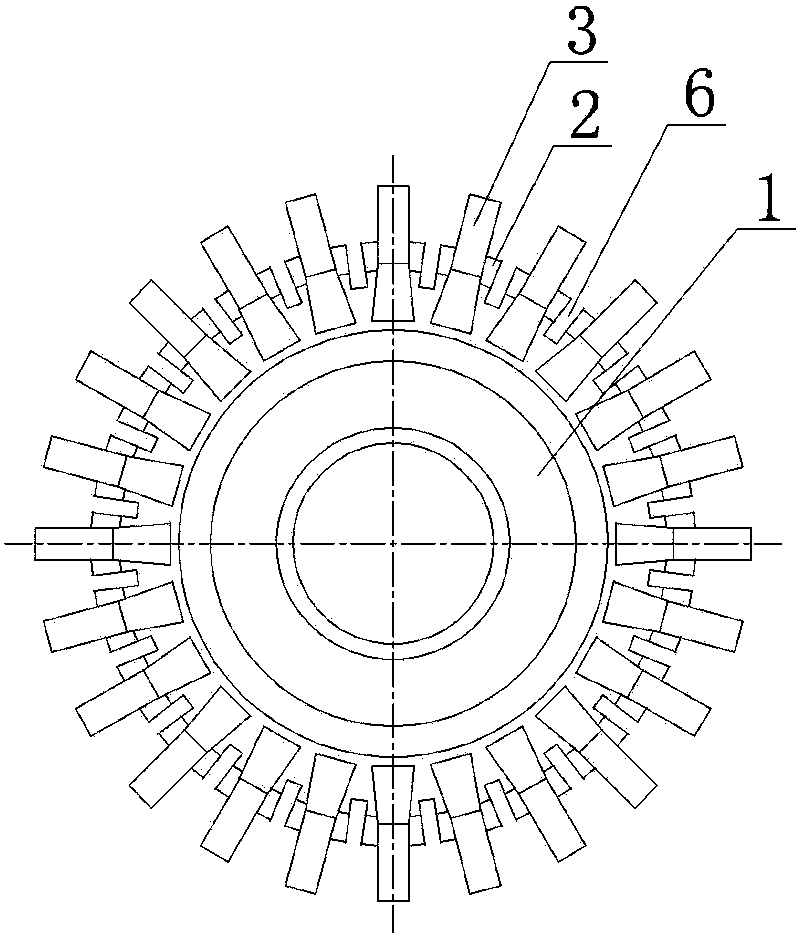

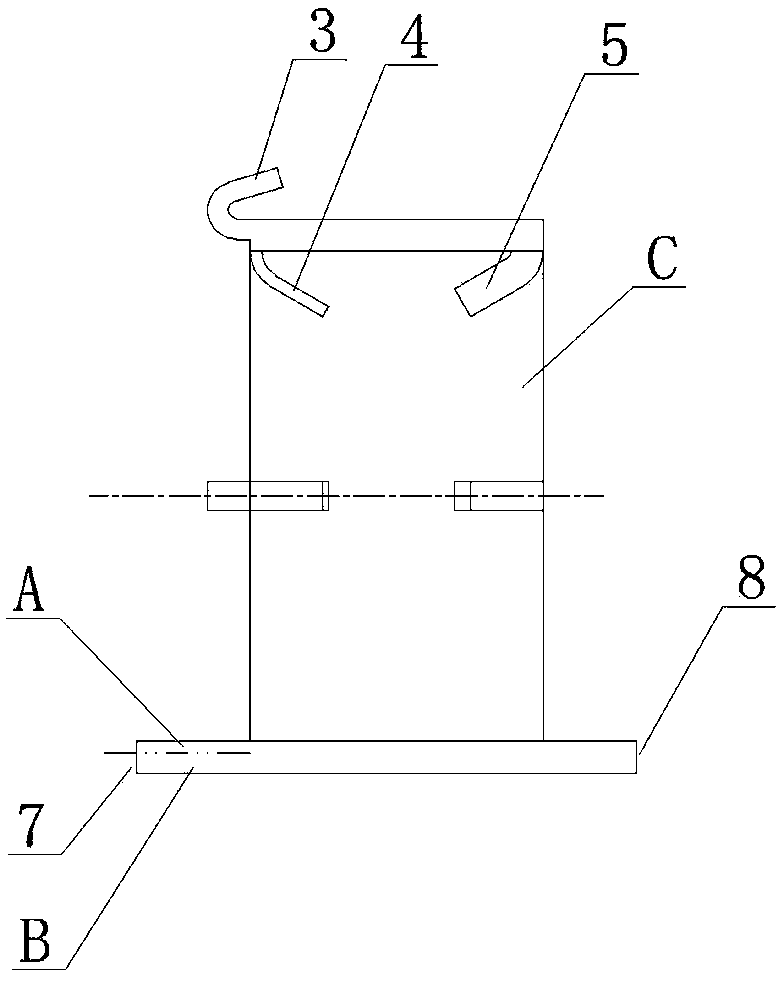

[0026] like Figure 1-5 As shown, the hook-type commutator product includes an insulator 1 and twenty-four pieces of commutation segments 2 arranged on the outer circle of the insulator 1. The top of the commutation segment 2 is provided with a hook 3, and the inner side of the commutation segment 2 is provided with an upper hook foot. 4 and the lower hook foot 5 are combined with the insulator 1. The commutator segment 2 is a cylindrical copper shell C before the inter-plate insulation groove 6 is opened. The upper and lower ends of the cylindrical copper shell C are equidistantly provided with upper bars Shape body 7 and lower strip shape body 8, upper strip shape body 7 is divided into inner and outer parts in the direction of wall thickness, and inner part A forms described upper hook foot 4 after bending inwardly, forms described bend after outer part B bends outwards. The hook 3 and the lower strip body 8 are bent inwardly to form the lower hook foot 5, and the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com