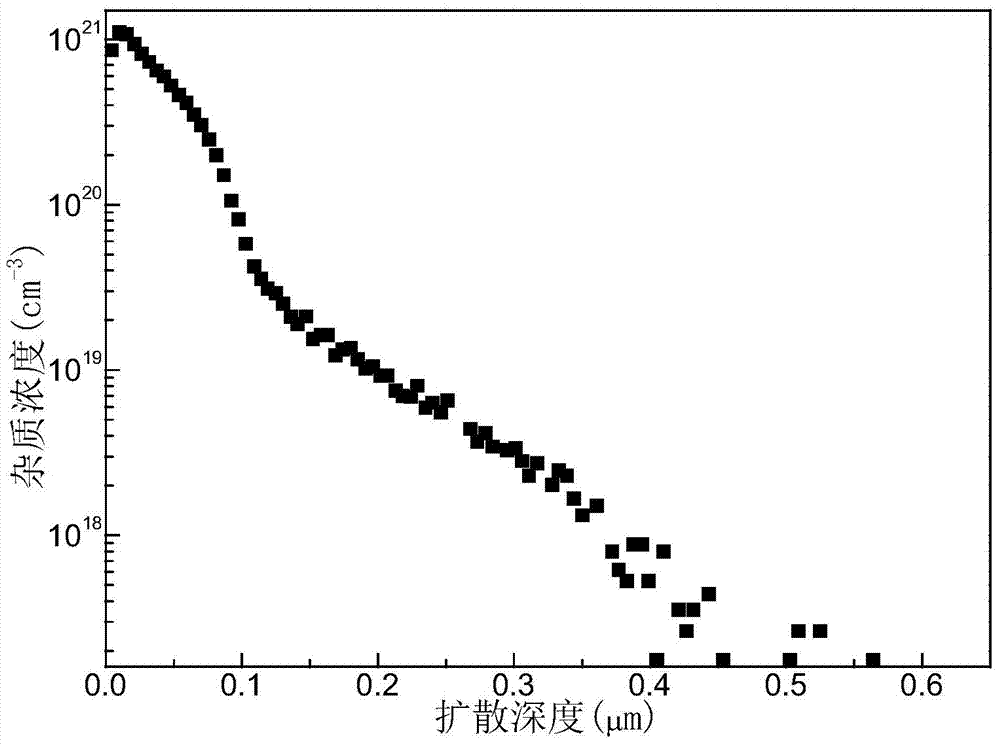

Method for manufacturing selective emitter structure with low surface concentration and soft doped zone

A lightly doped region, selective technology, used in climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of improving the conversion efficiency of solar cells with selective emitter structure and reducing the selective emitter structure. The conversion efficiency of solar cells does not avoid the problems of high temperature diffusion of phosphorus oxychloride liquid source, so as to shorten the preparation cycle, improve the output performance of the battery, and improve the uniformity and concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. The substrate is 156×156mm 2 The P-type crystalline silicon wafer (polycrystalline) is subjected to acid etching for texturing, RCA cleaning, and nitrogen blow-drying before use.

[0035] 2. Soak the clean silicon wafer prepared in step 1 in nitric acid solution, carry out wet chemical oxidation on the surface of the silicon wafer to make the surface hydrophilic, and then use nitrogen to dry the silicon wafer for later use, or Tumble dry or tumble dry.

[0036] 3. Prepare a phosphorus salt solution with a concentration of 1.0%wt. as a high-temperature diffusion source in the lightly doped region of the selective emitter structure. After the solution preparation is completed, the prepared phosphorus salt solution is evenly spin-coated and deposited on the surface of the silicon wafer prepared in step 2 by using a glue homogenizer to form a phosphorus salt diffusion source, and then dried for use.

[0037] 4. Use screen printing to deposit silicon ink on the surface ...

Embodiment 2

[0043] 1. The substrate is 156×156mm 2 The P-type crystalline silicon wafer (polycrystalline) is subjected to acid etching for texturing, RCA cleaning, and nitrogen blow-drying before use.

[0044] 2. Soak the clean silicon wafer prepared in step 1 in the RCA-No. 2 solution, perform wet chemical oxidation on the surface of the silicon wafer to make the surface hydrophilic, and then use nitrogen to dry the silicon wafer for later use , can also be tumble dried or tumble dried.

[0045] 3. Prepare a phosphorus salt solution with a concentration of 0.5% wt. as a high-temperature diffusion source in the lightly doped region of the selective emitter structure. After the solution preparation is completed, the prepared phosphorus salt solution is evenly spin-coated and deposited on the surface of the silicon wafer prepared in step 2 by using a glue homogenizer to form a phosphorus salt diffusion source, and then dried for use.

[0046] 4. Use screen printing to evenly spin-coat the...

Embodiment 3

[0052] 1. The substrate is 156×156mm 2 The P-type crystalline silicon wafer (polycrystalline) is subjected to acid etching for texturing, RCA cleaning, and nitrogen blow-drying before use.

[0053] 2. Soak the clean silicon wafer prepared in step 1 in the RCA-No. 3 solution, perform wet chemical oxidation on the surface of the silicon wafer to make the surface hydrophilic, and then use nitrogen to dry the silicon wafer for later use , can also be tumble dried or tumble dried.

[0054] 3. Prepare phosphorus salt aqueous solution with a concentration of 20.0%wt. as a high-temperature diffusion source in the lightly doped region of the selective emitter structure. After the solution preparation is completed, the prepared phosphorus salt source solution is evenly spin-coated and deposited on the surface of the silicon wafer prepared in step 2 by using a glue homogenizer to form a phosphorus salt diffusion source, and then dried for later use.

[0055] 4. Use screen printing to u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com