Movable tensile cable

A tensile and cable technology, applied in the direction of insulated cables, cables, circuits, etc., to achieve stable performance, excellent shielding performance, and increase anti-aging and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing, the present invention will be further described;

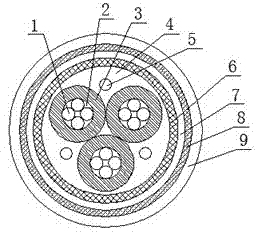

[0009] Such as figure 1 As shown, a mobile tensile cable is composed of an active power core, an alloy lead sheath shielding layer 7, a steel clad armor layer 8 and a silicone rubber outer sheath 9, and the active power core is made of natural butyl The styrene rubber insulating layer 3 is extruded and wrapped on four closely extruded aluminum alloy conductors 1, and a flame-retardant filling rope 2 is arranged in the gap in the main power line core; the water-blocking tape is wrapped around the cladding layer 6 to wrap three main power conductors. The wire core is a cable core; the gap in the cable core is provided with a foam rubber filling layer 4, and three tensile steel wires 5 are evenly arranged in the foam rubber filling layer 4; the alloy lead sheath shielding layer 7, steel ladle The armor layer 8 and the silicone rubber outer sheath 9 are extruded on the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com