Danger source supervision system and method

A technology of supervision system and hazard source, applied in the field of construction, can solve the problems of lack of timeliness, slow circulation of documents, long cycle, etc., and achieve the effect of fast application and approval, and flexible collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

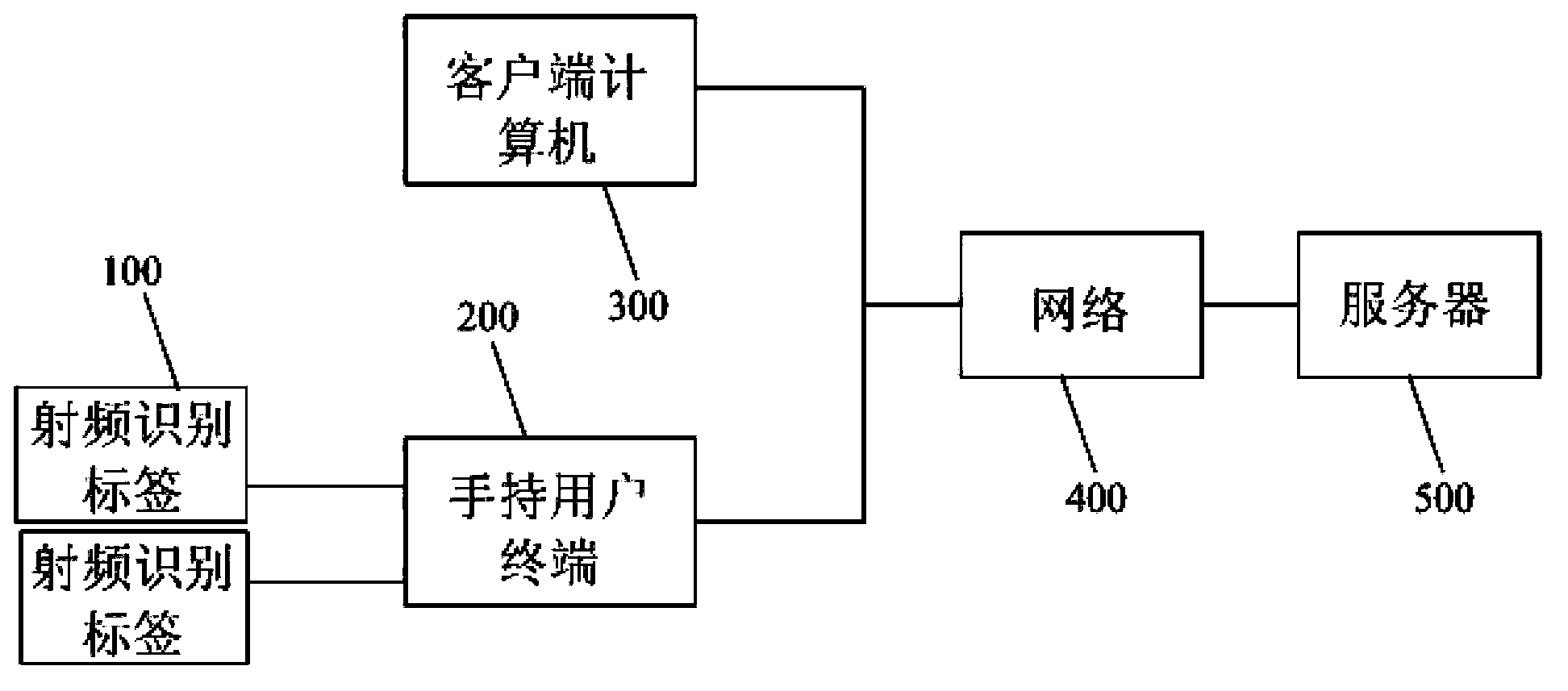

[0043] The following will combine figure 1 The detailed description of the hazard monitoring system and hazard monitoring method provided by the present invention is only a preferred embodiment of the present invention, and it can be considered that those skilled in the art can modify and polish it within the scope of not departing from the spirit.

[0044] Please refer to figure 1 , this embodiment provides a hazard monitoring system for monitoring the safety of hot work, including:

[0045] The server 500 is used to run the module of the hazard location supervision system, and open ports that can be accessed by client computing;

[0046] At least one client computer 300 is connected to the server 500 through the network 400, and is used to run a browser module capable of resolving the module of the hazard location supervision system and interacting with the server 500;

[0047] At least one hand-held user terminal 200 is connected to the server 500 through a network to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com