Accuracy judging method of weighing system composed of multiple electronic belt scales

An electronic belt scale and accuracy technology, applied in the field of tobacco processing, can solve the problem that the accuracy of weight measurement of admixed materials and mixed materials cannot be judged in time, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

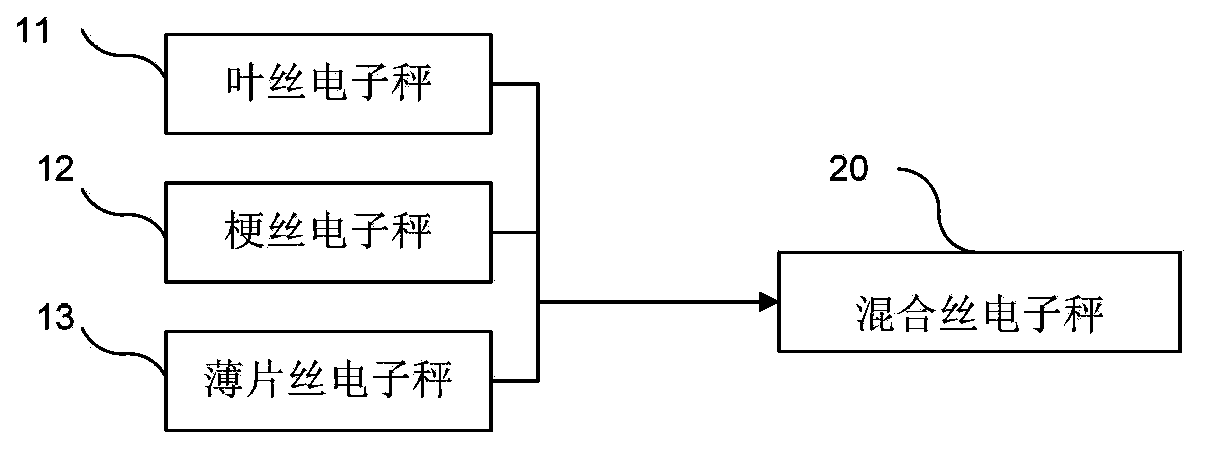

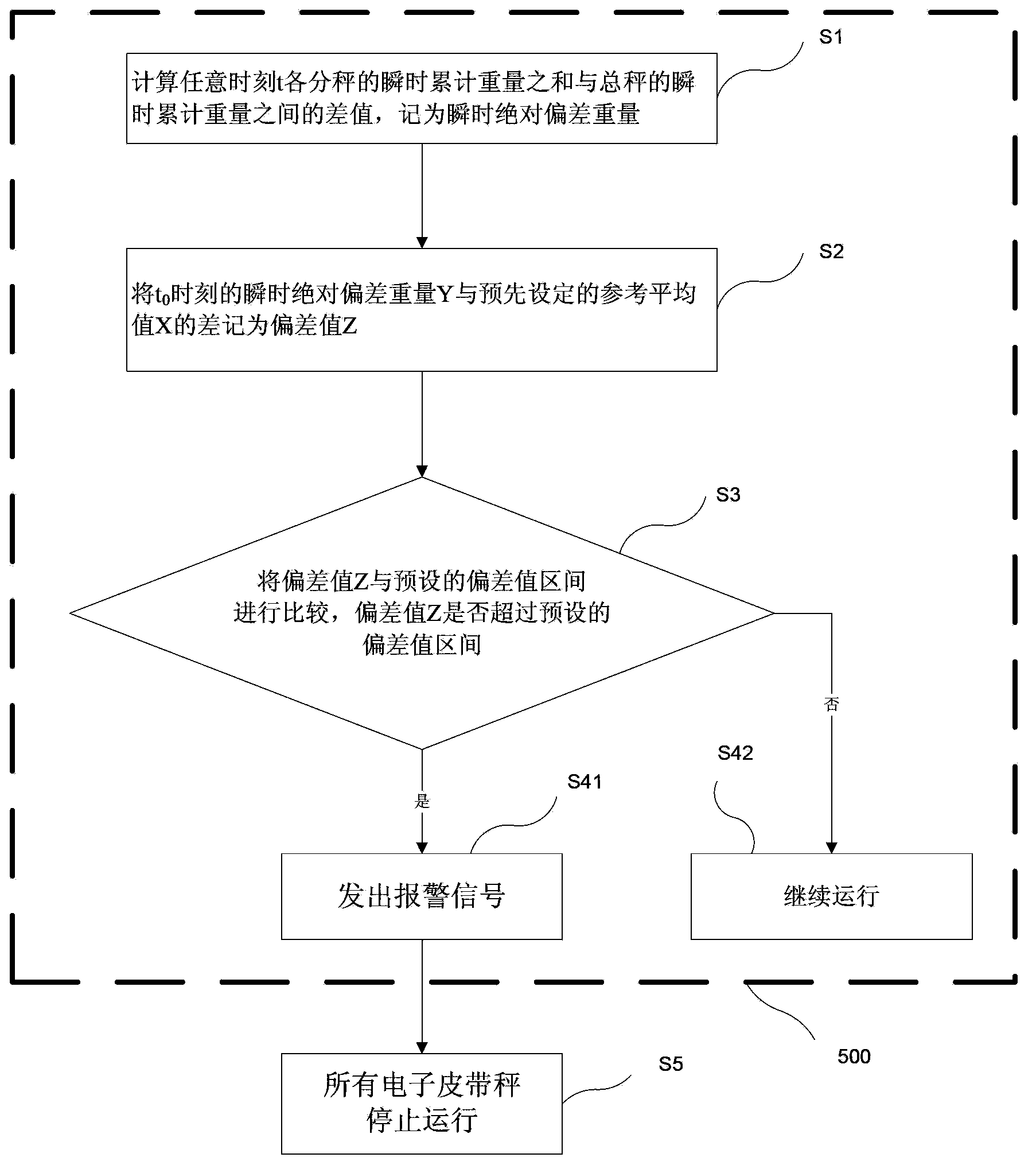

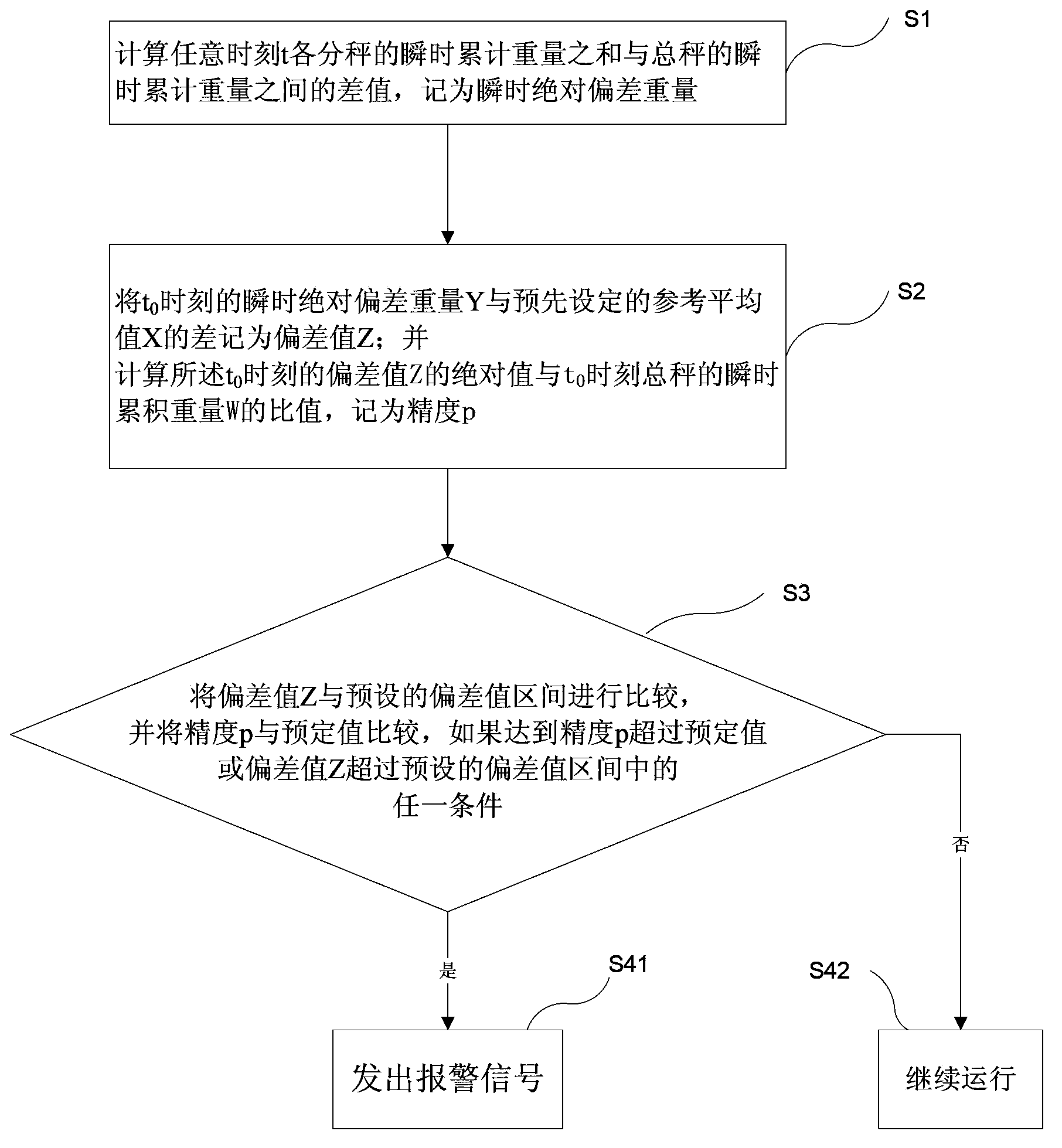

[0024] Refer to the following figure 1 Take the weighing system used in the blending and flavoring process in the tobacco processing process as an example to illustrate. As mentioned above, in this weighing system, the shredded leaves scale 11, the shredded stem scale 12, and the shredded shredded scale 13 are all sub-scales, and are used to weigh the mixed shredded weight of shredded shredded leaves, shredded shredded stems and shredded shredded shreds. Scale 20 is total scale. Both the sub-scales and the total scale are electronic belt scales operated under the control of a control computer. figure 2 It is a flow chart of the method for judging the accuracy of a weighing system composed of multiple electronic belt scales in Embodiment 1 of the present invention, wherein the flow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com