Checking tool for engine oil pan and method for measuring oil pressure strength using the checking tool

A technology for engine oil and oil pan, applied in the direction of applying stable tension/pressure to test material strength, mechanical measuring device, mechanical counter/curvature measurement, etc., can solve the problems of low efficiency, high cost, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

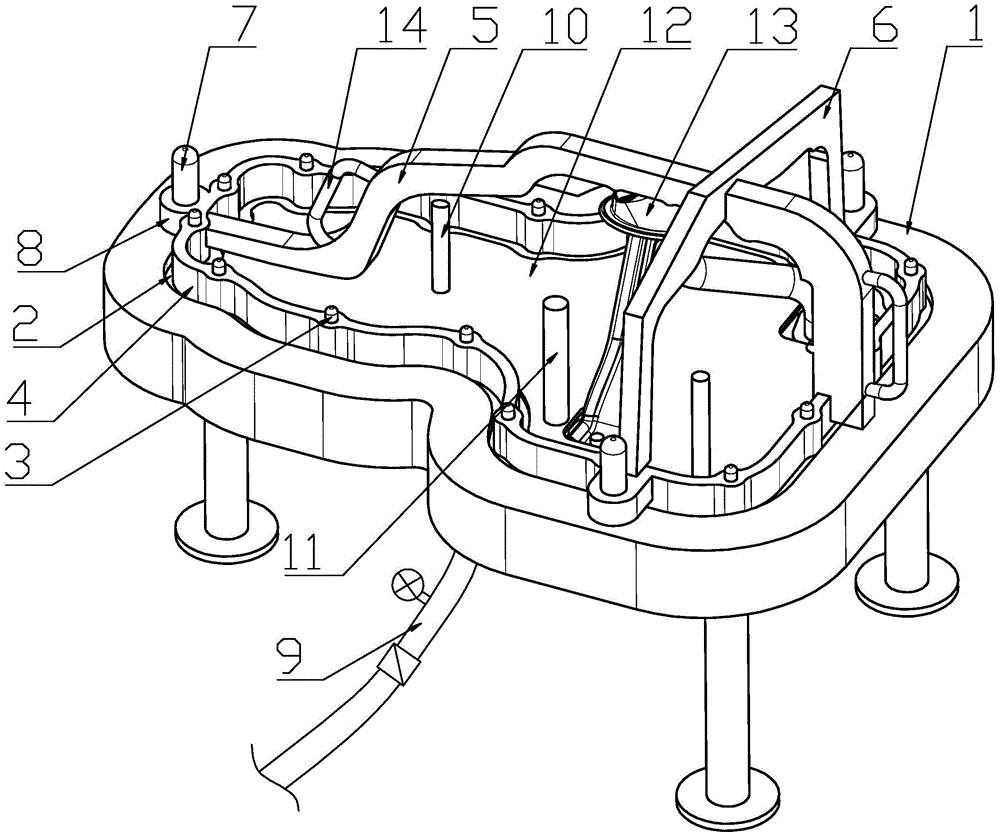

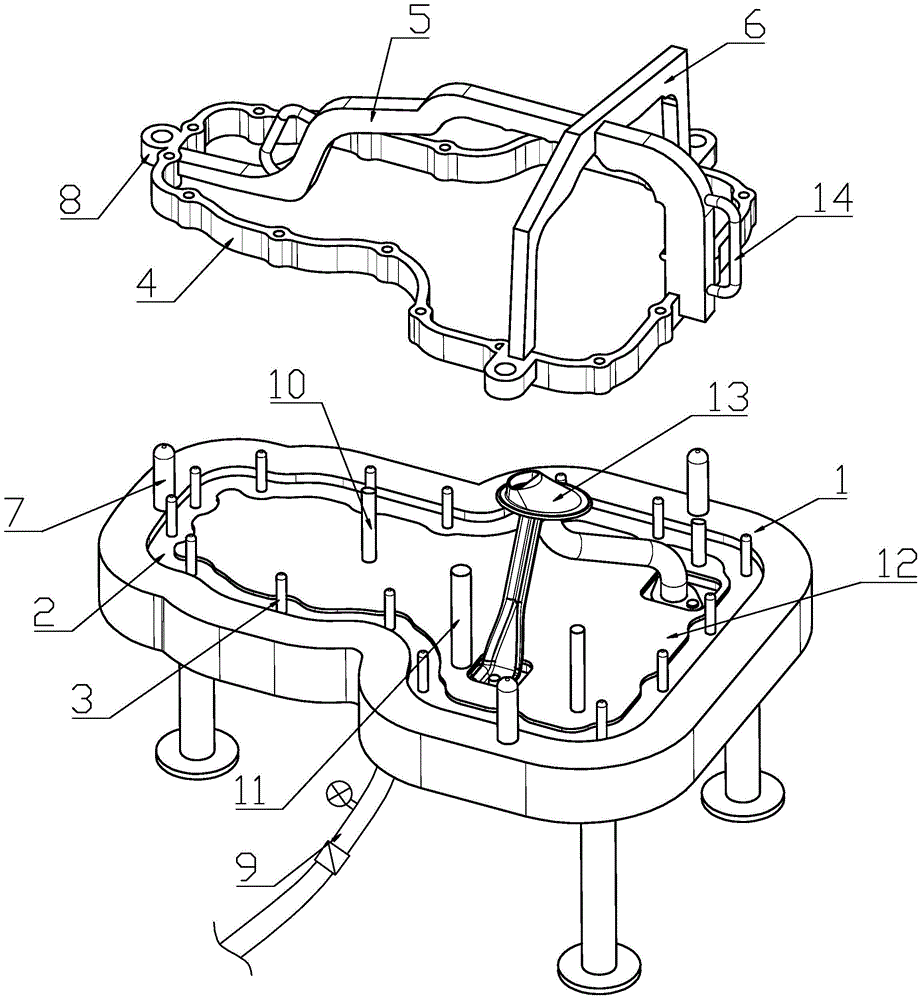

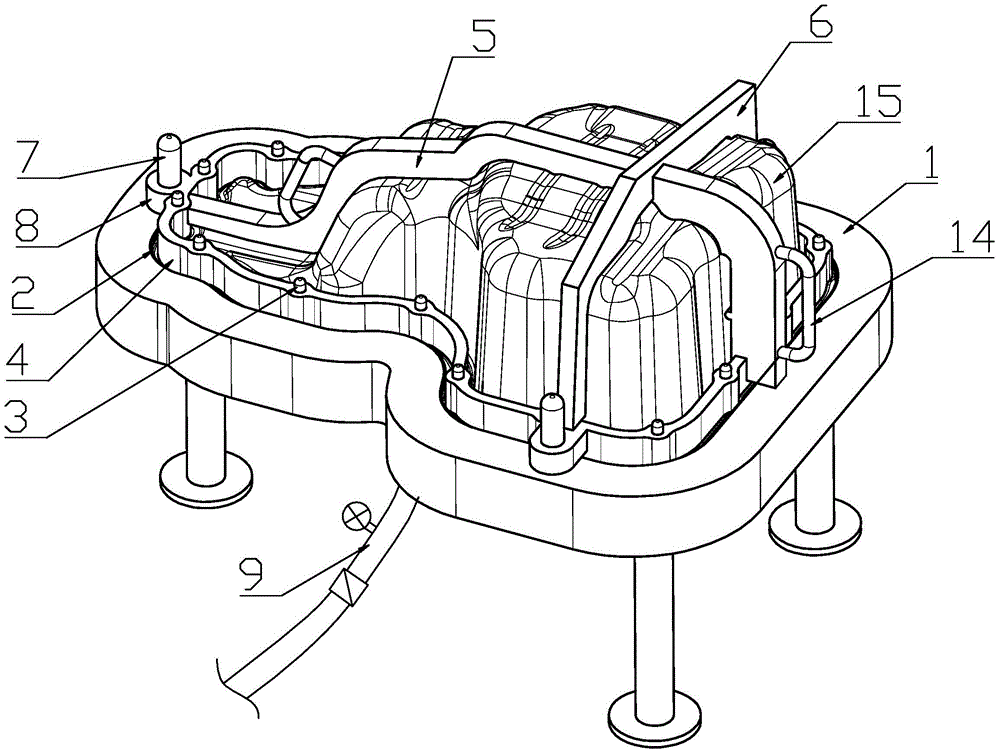

[0025] Attached to the manual figure 1 , 3 As shown, an engine oil pan inspection tool includes a horizontally placed operating platform 1, the bottom of the operating platform 1 is provided with feet, and the operating platform 1 is provided with a lower groove 2 that matches the shape of the outer edge of the oil pan 15, Fourteen locating pins 3 connected to the oil pan 15 are provided on the operating platform 1 along the inner edge of the lower groove 2. The positions and numbers of the locating pins 3 and the mounting holes of the oil pan 15 correspond one-to-one, as shown in the manual attached Figure 4 As shown, the lower groove 2 is provided with a first detection rod 10 connected to the oil baffle 16 on the inner side of the oil pan 15, there are three first detection rods 10, and the three first detection rods 10 are vertically arranged and The end of the first detection rod 10 is in contact with the oil baffle 16 , and the lower groove 2 is provided with a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com