Bidirectional heat exchange electric shower with nonmetal electrothermal film heating pipes

An electric heating film tube and electric heating film technology, applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of wasting energy consumption, low energy efficiency ratio, and large waste of radiant energy, etc., to overcome the inability to fully Effects of heat exchange, safety improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical solution of the present invention, the following specific embodiments are described in detail in conjunction with the accompanying drawings:

[0021] The invention discloses a two-way heat exchange non-metal electric heating film heating pipe electric shower, which is an improved design for the existing electric heater. Under the control of the computer, it can be turned on and used immediately, and hot water can be provided immediately and quickly for use, so as to achieve on-demand heating, save electric energy, reduce use costs and improve safety performance.

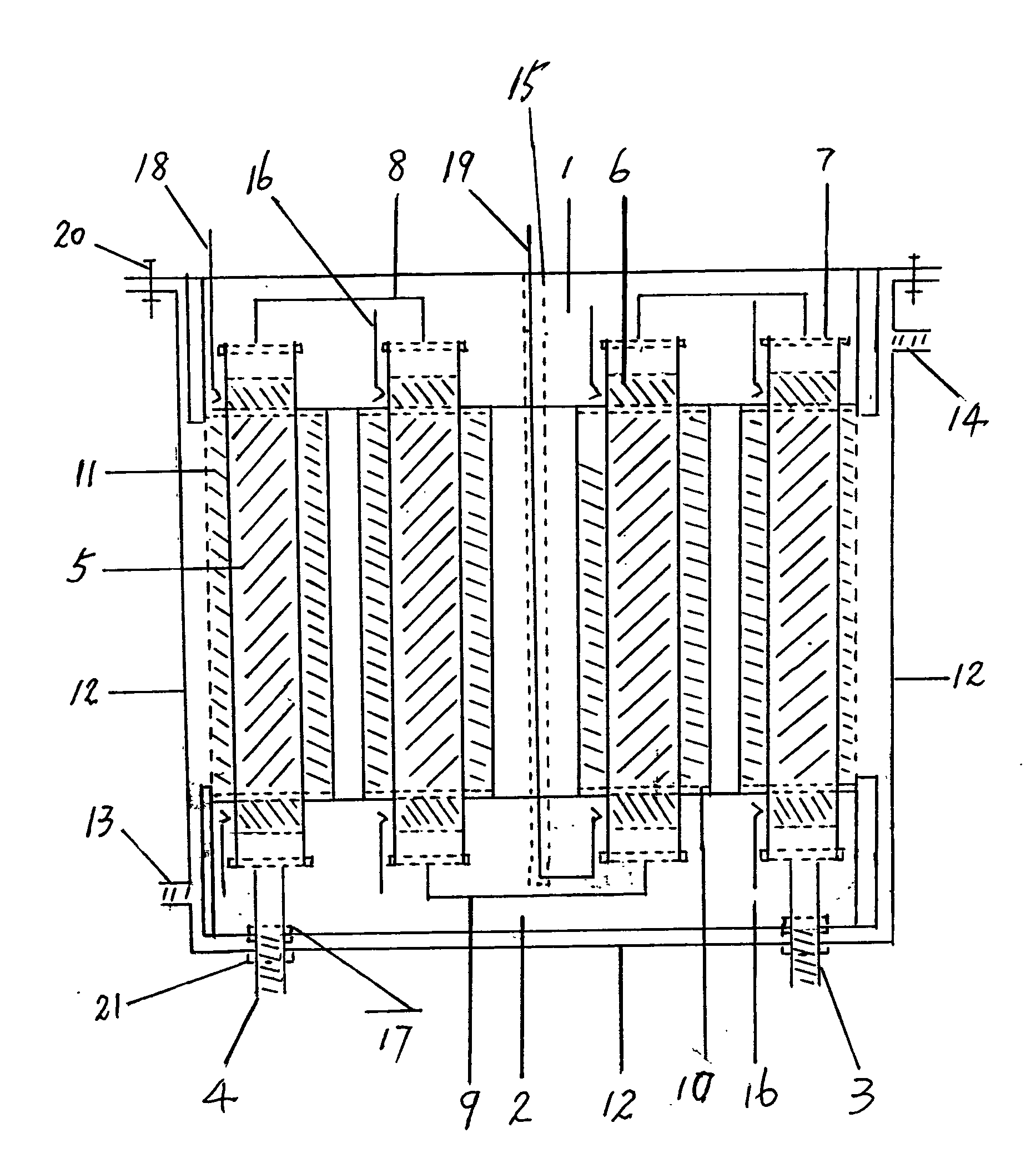

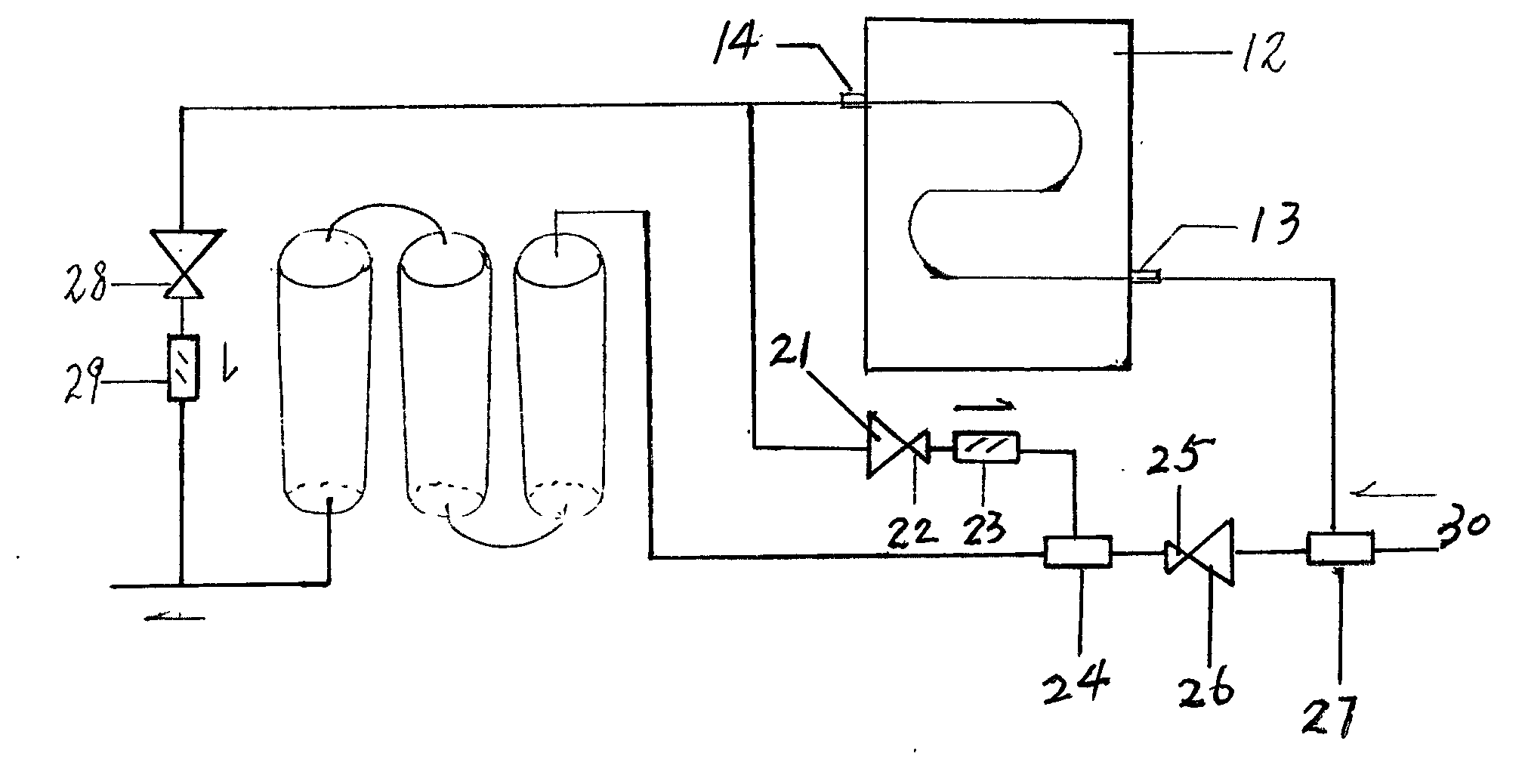

[0022] See attached figure 1 , attached figure 2

[0023] attached figure 1

[0024] Upper water distribution splint (1) Lower water distribution splint (2) Cold water inlet (3) Hot water outlet (4) Electrothermal film tube (5) Silver-plated conductive electrode (6) O-ring seal (7) Upper Water distribution tank (8) Lower water distribution tank (9) O-type seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com