A multi-stage combined louver air outlet of a central air conditioner

A central air conditioner and air outlet technology, applied in the direction of airflow control components, etc., can solve the problems of time-consuming and labor-intensive production and assembly, inconvenient mass production, and many sizes and specifications, so as to prevent the accumulation of condensed water, facilitate mass production, and simple processing and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

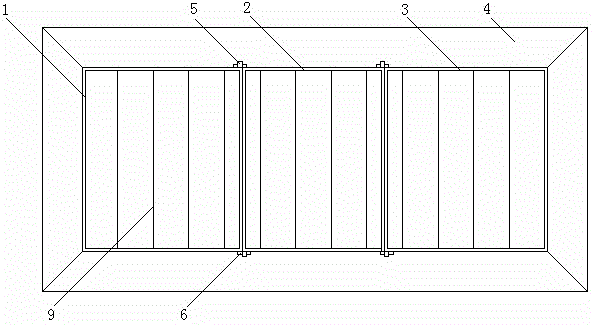

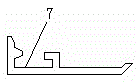

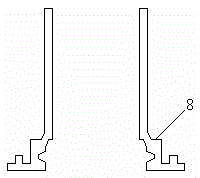

[0028] Referring to the accompanying drawings, this embodiment includes the first section of the air outlet 1, the middle section of the air outlet 2, the tail section of the air outlet 3 and the decorative strip 4, one side of the connecting end of the first section of the air outlet 1 is provided with a card slot 5, and the other The side is provided with a buckle 6 that coincides with the slot 5, and the two ends of the middle section of the air outlet 2 and the connecting end of the tail section 3 of the air outlet are respectively provided with corresponding slots and buckles, and the first section of the air outlet 1. The middle section 2 of the air outlet and the tail section 3 of the air outlet are connected by slots and buckles. A series of installation holes are respectively provided on the frames 8 of the first section 1 of the air outlet, the middle section 2 of the air outlet, and the tail section 3 of the air outlet. I (not shown in the figure), the installation h...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that there is no need to set reinforcing strips; there is a rectangular Hole 14 and fastening hole II15, the rectangular hole 14 communicates with the installation hole I, the fastening hole II15 communicates with the rectangular hole 14, the air guiding strip is provided with a connecting section II16, and the connecting section II16 is placed horizontally When it is placed vertically, it can pass through the rectangular hole 14, and when it is placed vertically, it will be stuck in the fastening hole II 15, so that the air guide strip can be connected stably.

[0033] The above-mentioned embodiments all have a middle section of the air outlet, but in actual situations, the air outlet may only be composed of a combination of the first section of the air outlet and the tail section of the air outlet, and no more examples are given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com