Biomass fuel waste heat recycling cooking range

A biomass fuel and waste heat recovery technology, which is applied in the direction of stoves/stoves with hot water devices, household stoves/stoves, solid heating fuels, etc., can solve the adverse effects of the surrounding environment, low heat utilization rate, inconvenient use, etc. problem, to achieve the effect of simple structure, high heat absorption rate and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

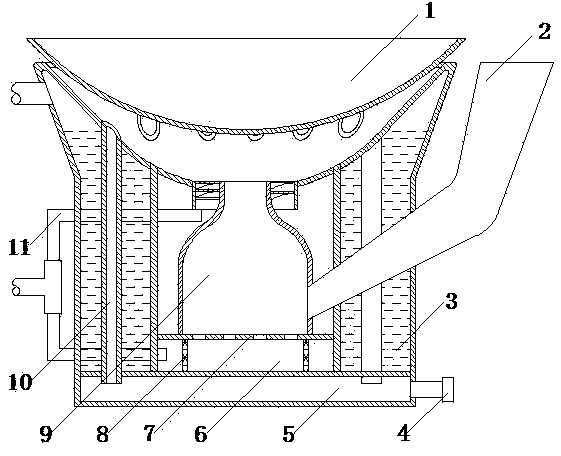

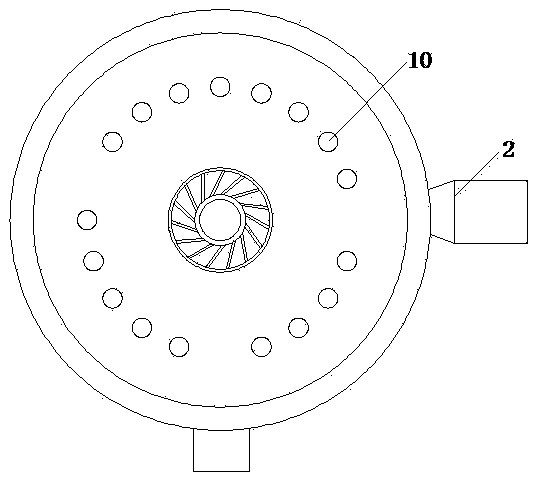

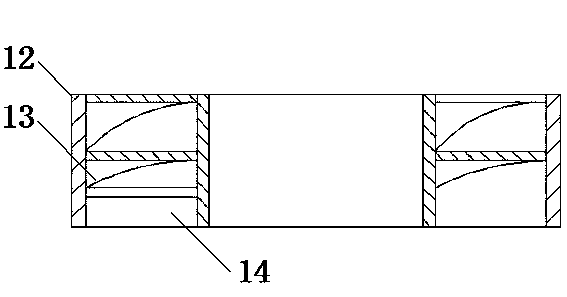

[0032] Such as figure 1 , figure 2 , image 3As shown, the biomass fuel waste heat recovery stove of the present invention includes a furnace 9 surrounded by high-temperature resistant materials and a blower; The bottom of the furnace bridge 7 is provided with an ash accumulation cavity 6 . The furnace is provided with a feed inlet, which extends outside the furnace wall through a tube or bucket 2 . The air outlet of the blower communicates with the ash chamber 6 through a pipeline. It also includes a waste heat recovery cavity 3 , a hot air pipe 10 and an induced draft fan 4 . The frying pan 1 is sealed and connected with the top of the hearth to form a heating zone. The waste heat recovery chamber is arranged around the furnace and isolated from the heating area on the top of the furnace. A steam outlet is provided on the top of the waste heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com