Connecting and replacing construction method for underground water supply glass reinforced plastic sand pipes and steel pipes

A technology of sand-filled pipes and FRP, which is applied in the direction of pipes/pipe joints/fittings, pipe components, pipeline laying and maintenance, etc., and can solve the problems of poor pressure bearing capacity of FRP sand-filled pipes, blasting of FRP sand-filled pipes, and low efficiency of construction methods and other issues, to achieve the effect of improving construction quality, improving work efficiency, and improving the progress of rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

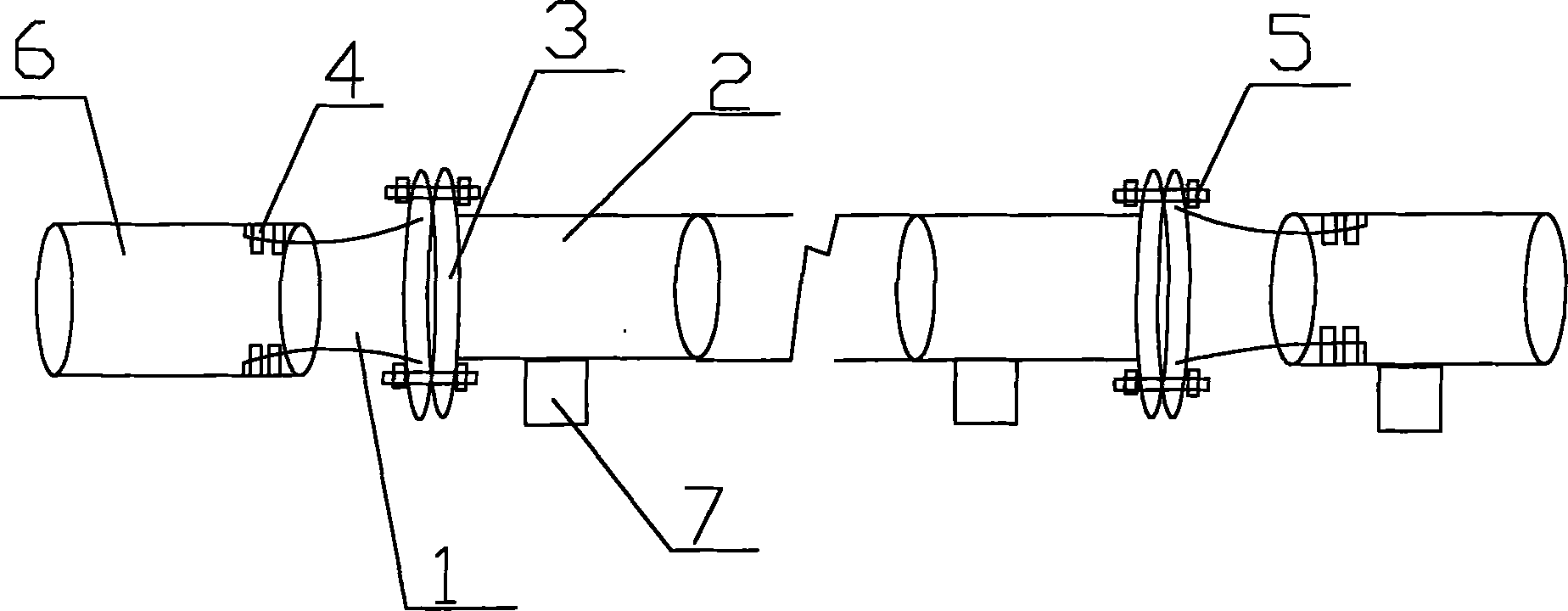

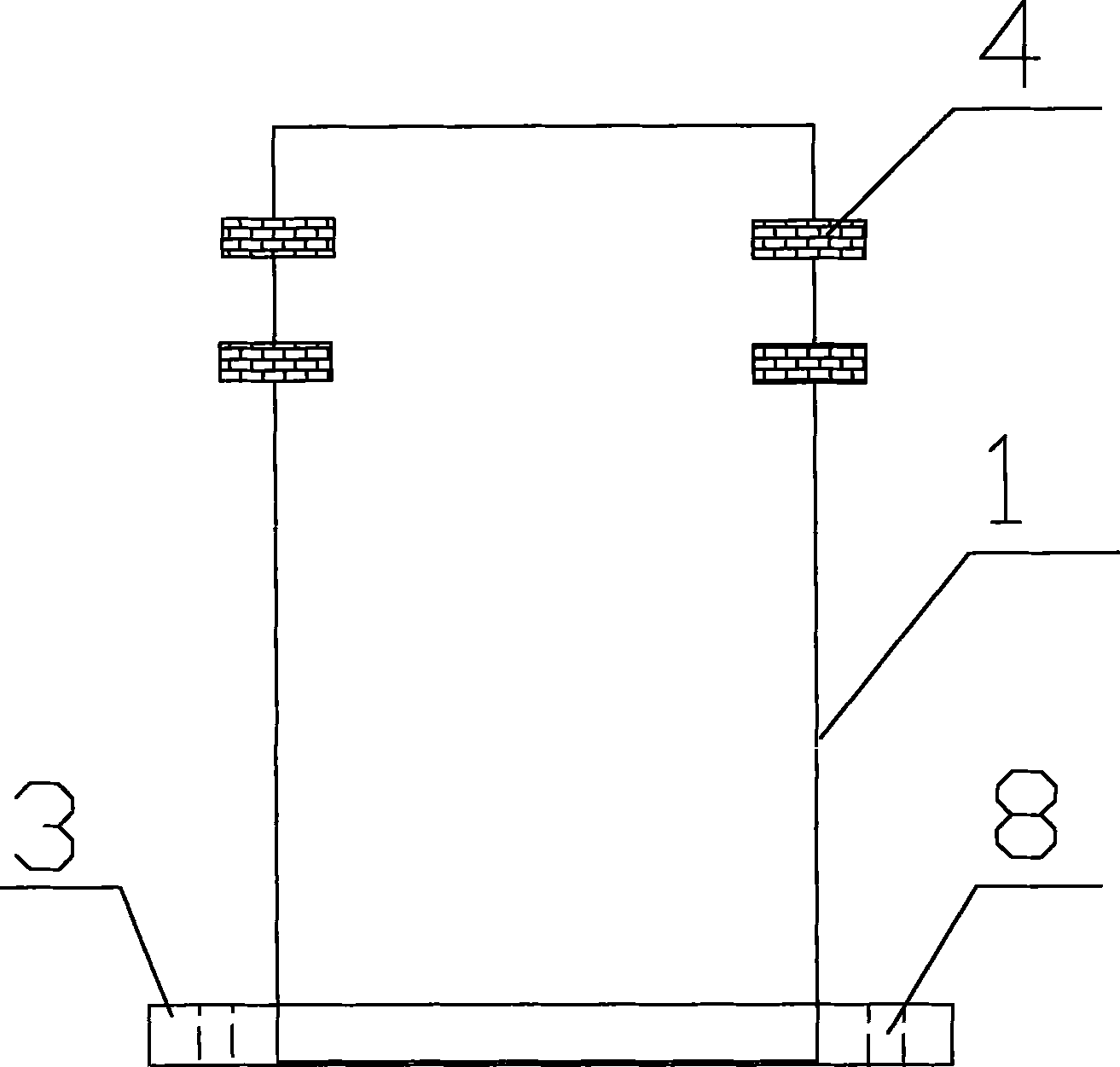

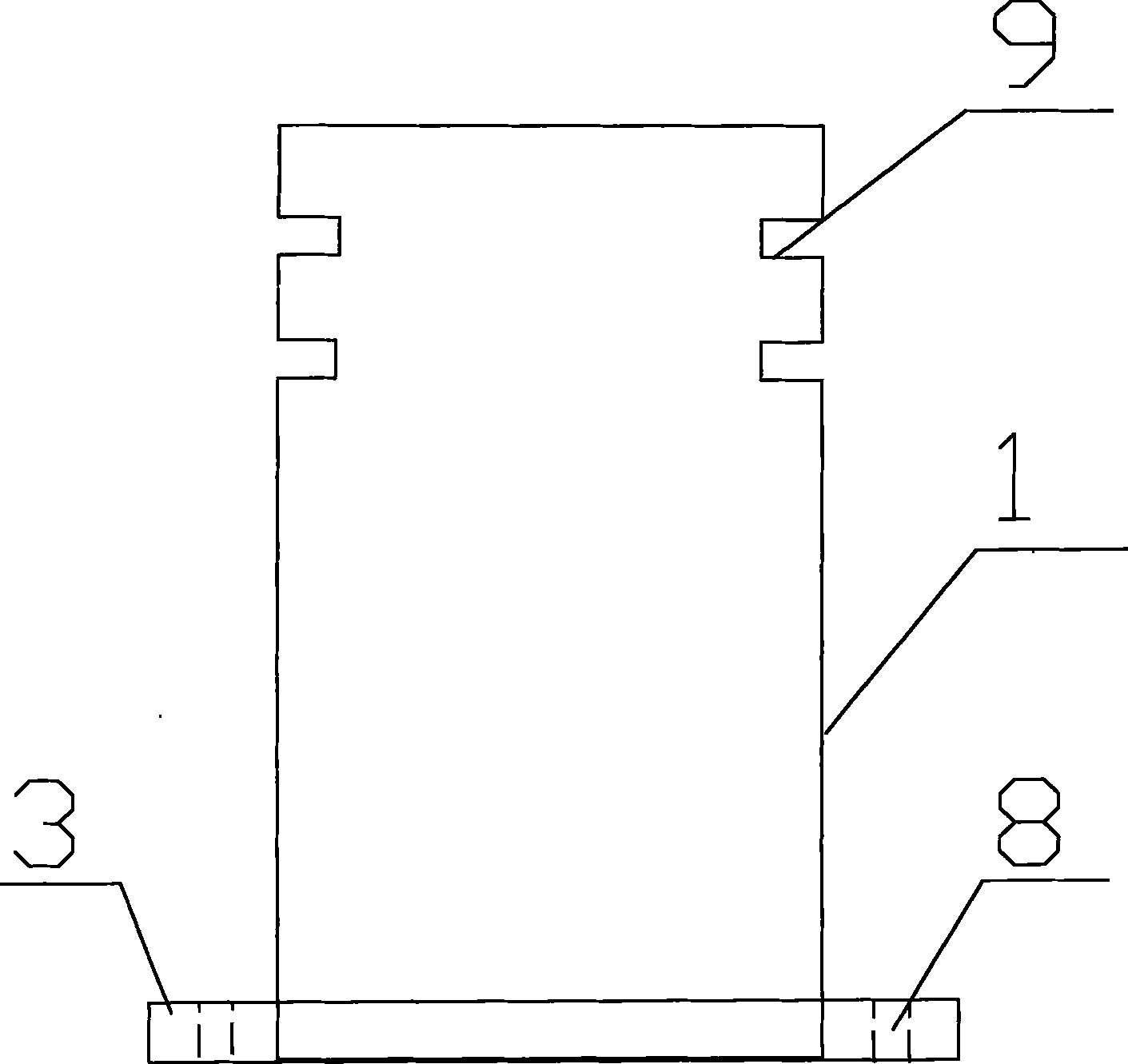

[0023] Such as Figure 1-7 As shown, a construction method for connecting and replacing an underground water supply FRP sand pipe and steel pipe, comprising the following steps:

[0024] 1) Preparation of materials and devices: According to actual needs, prepare two flange connection pipes 1, water supply steel pipe 2, reinforced concrete pier 7 and a number of backing plates with a thickness of 100mm and a specification of 1m×1m. One end of the two pipes is welded with a flange plate 3, and the inner wall of the other water supply steel pipe 2 is welded with two positioning steel plates 10 to prevent the butt joint misalignment of the steel pipe and the steel pipe. The flange connection pipe 1 has a flange plate 3 at one end and the water supply steel pipe The flange plate 3 of 2 is connected, and the outer wall of the other end is provided with a groove 9, and the groove 9 is filled with an elastic ring 4, and this end is inserted into a glass fiber reinforced plastic sand p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com