Novel high-pile wharf

A high-pile wharf, a new type of technology, is applied in the direction of coastline protection, jetty, pier, etc. It can solve the problems that the structure type of high-pile wharf cannot meet the engineering requirements, cannot bear the load of the stacked cargo, and the site conditions are complex, etc., to improve the storage yard. The effect of formation efficiency, reduction of uneven settlement, and strong foundation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

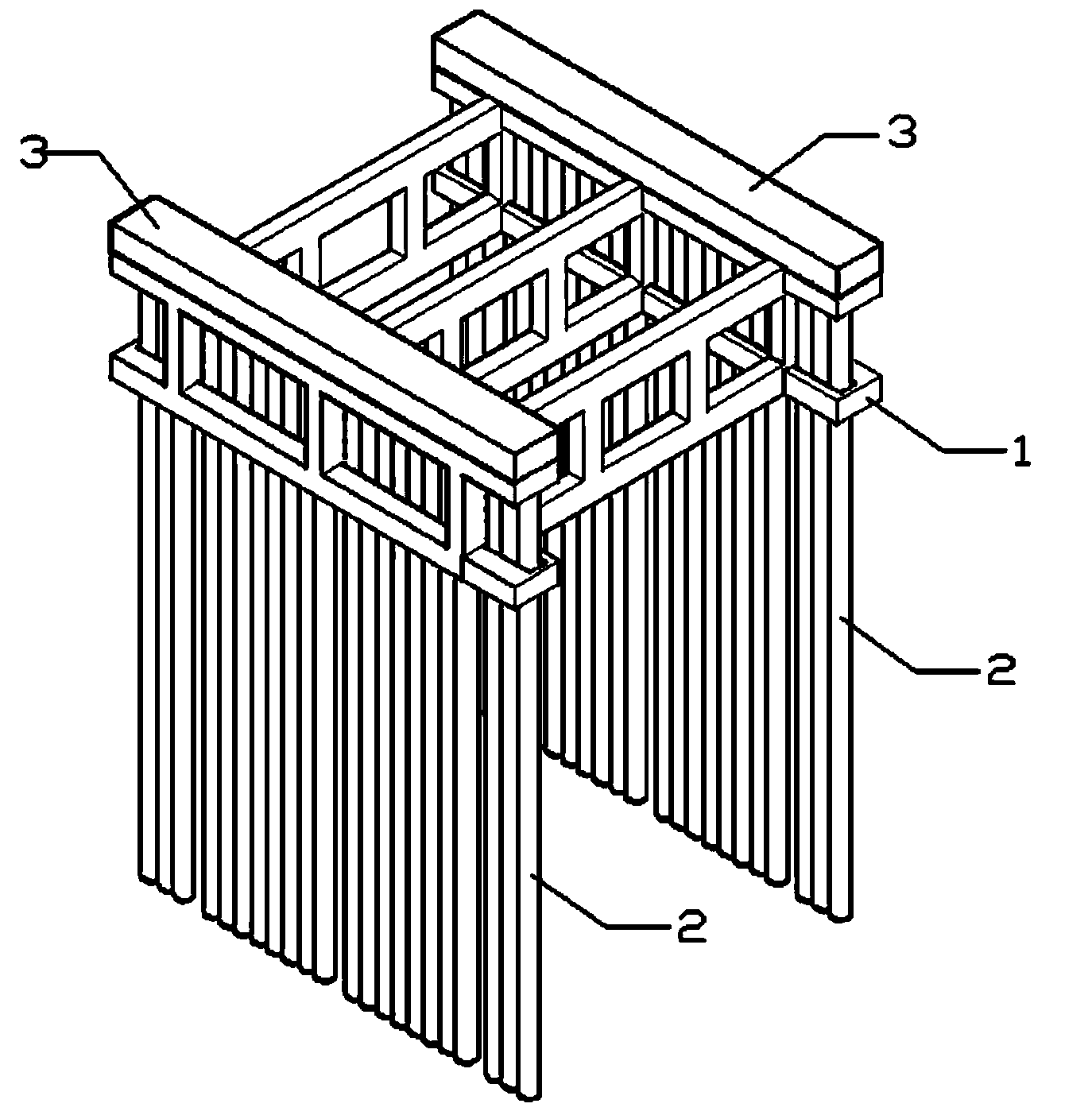

[0026] The structure type includes high pile pile platform, wall pile frame structure, ship berthing component 9 and surface layer 12, etc., the prefabricated ship berth component 9 is installed on the front side of the high pile pile platform, and the wheel protection rim 10 and 11 series are installed on the upper facing water surface. boat post. The shore structure of the wall pile frame is mainly composed of a precast concrete frame 1 and a number of precast piles 2. The precast concrete frame includes a guide beam 5, a connecting beam 6 and a column 7. The guide beam 5 and the connecting beam 6 form a square frame. The square frame constitutes an integral prefabricated concrete frame through upright columns 7. A number of reserved wall pile holes 4 are axially arranged on the front and rear guide beams of the prefabricated concrete frame, and several prefabricated wall piles 2 run through the reserved wall pile holes. The precast concrete frame is placed in The upper part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com