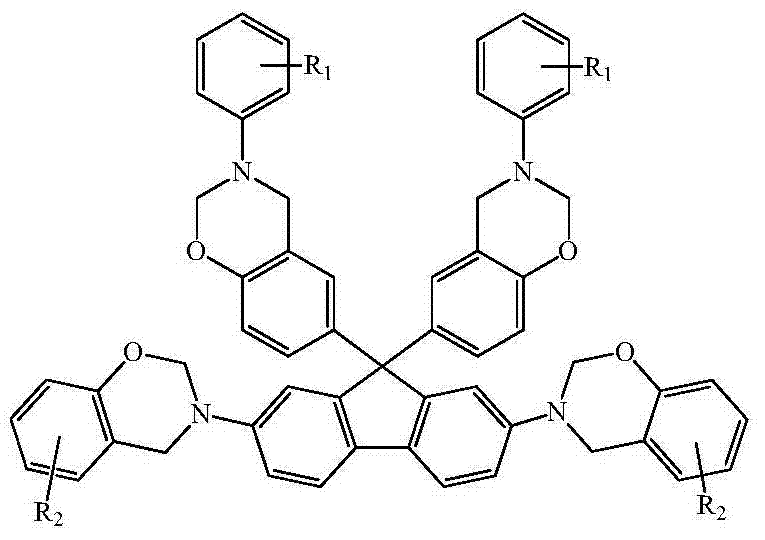

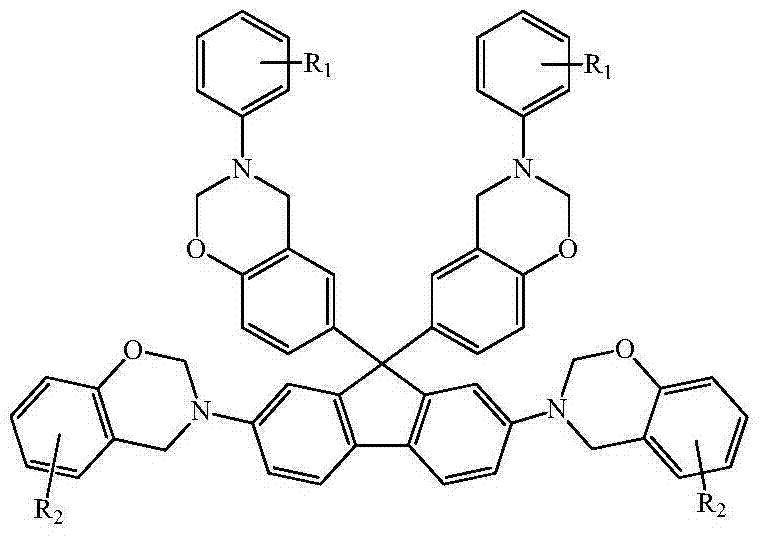

N-full-aromatic hydrocarbon diamine-bisphenol tetrafunctional fluorenyl benzoxazine and preparation method thereof

A fully aromatic hydrocarbon-based diamine and four-functionality technology, which is applied in organic chemistry and other fields, can solve problems such as difficulty in obtaining target products, and achieve the effects of expanding application fields, excellent flame retardancy, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

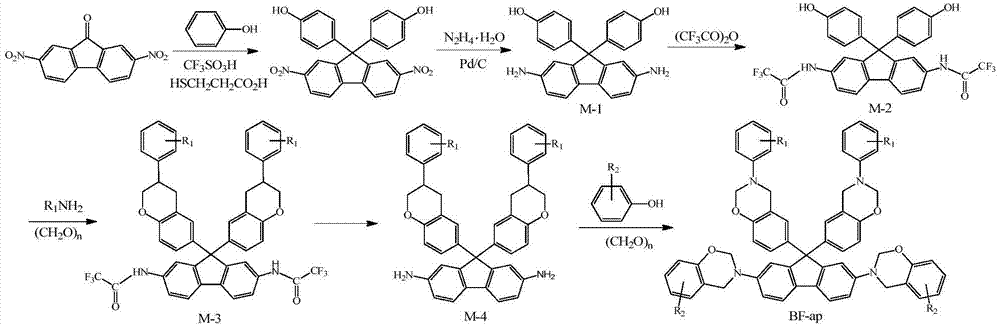

Method used

Image

Examples

Embodiment 1

[0033] (1) Synthesis of 2,7-diamino-9,9-bis-(4-hydroxyphenyl)fluorene

[0034] Add 0.01mol 2,7-dinitro-9-fluorenone, 0.08mol phenol, 0.005mol trifluoromethanesulfonic acid and 0.001mol 3-mercaptopropionic acid to a three-necked flask with a stirring rotor, a condenser tube and a thermometer in sequence, Stirring was started, the reaction temperature was controlled at 55°C, and the reaction time was 3 hours. After the reaction, the product was washed with 20% ethanol solution for 3 to 5 times, and finally dried in vacuum to obtain 2,7-dinitro-9,9-bis -(4-hydroxyphenyl)fluorene, yield 86.8%; 0.05mol2,7-dinitro-9,9-bis-(4-hydroxyphenyl)fluorene, 100mL absolute ethanol and 2 grams of palladium carbon catalyst Add it into the above-mentioned three-necked flask, raise the reaction temperature to 85°C under stirring, then add dropwise 0.47mol80% hydrazine hydrate solution, finish the reaction after 36h, filter while it is hot, and remove most of the ethanol by distilling the filtrate...

Embodiment 2

[0046] Except that the aniline in the synthesis step (3) was changed to m-methoxyaniline, the organic solvent was changed from chlorobenzene (5mL) and toluene (10mL) to chlorobenzene (10mL) and dioxane (10mL), and the reaction temperature was changed from 120 ℃ was changed to 100 ℃, the reaction time was changed from 4h to 12h, 0.045mol sodium borohydride was changed to 0.060mol potassium borohydride in the synthesis step (4), and the reaction time was changed from 7h to 4h, other conditions were the same as in Example 1. Finally, a phenol-m-methoxyaniline-derived N-fully aromatic hydrocarbon-based bisamine-bisphenol-type tetrafunctional fluorenyl benzoxazine (BF-ap-2), T m The temperature is 143°C, and the total yield of the product is 51.5% (calculated based on the yield of synthesis steps 2 to 5, the same below).

[0047] 1 H NMR: 6.60~7.94 (m, 28H, Ar-H), 5.43 and 5.38 (d, 8H, O-CH on fluorene ring and benzene ring, respectively 2 -N), 4.81 and 4.66 (d, 8H, Ar-CH on the fl...

Embodiment 3

[0050] Except that the aniline in the synthesis step (3) was changed to m-toluidine, the organic solvent was changed from chlorobenzene (5mL) and toluene (10mL) to chlorobenzene (10mL) and xylene (5mL), and the reaction temperature was changed from 120°C to 140°C °C, the reaction time was changed from 4h to 12h, the phenol in the synthesis step (5) was changed to cardanol, the organic solvents chlorobenzene (2mL) and xylene (10mL) were changed to chlorobenzene (10mL) and toluene (6mL), and the reaction temperature Change from 140°C to 110°C, change the reaction time from 12h to 24h, other conditions are the same as in Example 1, and finally obtain N-fully aromatic hydrocarbon diamine-bisphenol tetrafunctional fluorenyl derived from cardanol-m-toluidine Benzoxazine Monomer (BF-ap-3), T m It is 79 ℃, and the total yield of product is 50.4%.

[0051] 1 H NMR: 6.58~7.93 (m, 26H, Ar-H), 5.74~5.82 and 4.95~5.04 (m, =CH- and -CH=CH 2 ), 5.38 and 5.31 (d, 8H, O-CH 2 -N), 4.70 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com