Dual-phase ion exchange method for glass enhancement

An ion exchange method and ion exchange technology, applied in the field of glass-reinforced two-stage ion exchange method, can solve the problems of multiple procedures, complex operation process, high energy consumption, etc., achieve simple process, increase surface stress and stress layer depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

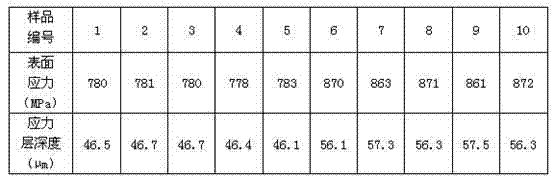

Embodiment 1

[0022] The material of the glass substrate is ordinary soda-lime-silica glass, and the process includes washing, preheating, chemical tempering, cooling and other processes of the original glass sheet; 10 minutes, rinse with pure water and dry for later use, then place the clean original glass piece on the rack, put it together with the rack into the preheating furnace for preheating, the temperature rise rate of the preheating furnace is 5°C per minute , when it rises to 300°C, keep it warm for 30 minutes, then put the glass into the molten salt for ion exchange, the temperature of the molten salt is 450°C, and the ion exchange time is 4 hours; the molten salt is potassium nitrate molten salt, no other additive.

[0023] After the ion exchange in this step, take out 5 pieces of glass with glass numbers 1-5 and quickly put them into the annealing furnace to cool down. Take out the glass from the furnace door, wash the molten salt attached to the glass surface and dry it.

[...

Embodiment 2

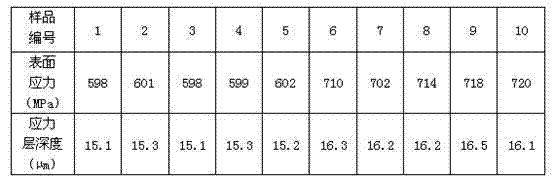

[0028] The difference between this embodiment and Embodiment 1 is that the original glass sheet is made of alkali aluminosilicate glass with a thickness of 0.7 mm and an aluminum content of about 14% (mass percentage).

[0029] The test results are as follows:

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com