A kind of black fluorine-free glass-ceramic for tombstone and its preparation method

A technology of glass-ceramics and black, which is applied in the field of black fluorine-free glass-ceramics for tombstones and its preparation. It can solve the problems of unstable slag composition, shortened kiln life, and difficult production control, and achieves good color brightness and energy saving. Process steps, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

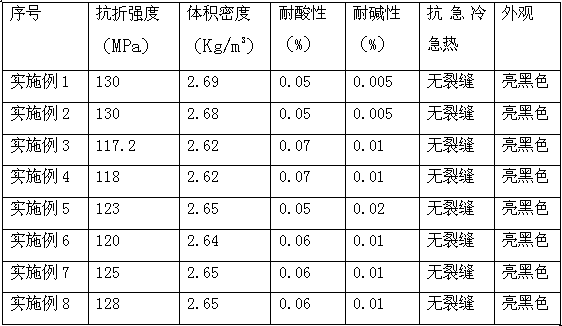

Examples

Embodiment 1

[0058] The weight percentages of glass are:

[0059] SiO 2 : 49.6%; Al 2 o 3 : 18.4%; CaO: 10%; MgO: 5%; Na 2 O: 9.1%; TiO 2 : 4%; Fe 2 o 3 : 3%; Co 2 o 3 : 0.2%; Ni 2 o 3 : 0.7%.

[0060] The preparation method is:

[0061] a) Calculate and accurately weigh according to the composition design formula, use a single-head ball mill, and mix for 15 minutes with a material-to-ball ratio of 1:2 to obtain a uniformly mixed glass batch;

[0062] b) Melt the above-mentioned batch materials in a high-temperature lifting furnace at a temperature of 1590°C for 3.5 hours to obtain a clear and uniform molten glass;

[0063] c) Pour the above-mentioned uniform glass liquid into a preheated graphite mold for molding to obtain a black glass-ceramic matrix;

[0064] d) Put the above-mentioned matrix glass-ceramic directly into the crystallization furnace, hold at 750°C for 1 hour for nucleation, hold at 1040°C for crystallization for 1 hour, then hold at 840°C for 2 hours for heat...

Embodiment 2

[0066] The weight percentage of glass is the same as in Example 1.

[0067] Calendering preparation process is:

[0068] a) weighing, batching, and mixing uniformly according to the raw material components to obtain the batch;

[0069] b) Put the batch material prepared in step a) into the electric melting furnace, the melting temperature is 1590°C, and the uniform glass liquid enters the calender through the flow hole, the ascending channel, and the forehearth; the glass liquid cools down through the forehearth, enters the The temperature of the calender is 967°C, and the temperature of the exit calender roll is about 846°C, forming a glass plate with a thickness of 18-20mm;

[0070] c) The glass plate obtained in step b) is sent to the heat treatment kiln through the transition roller table, nucleated at a nucleation temperature of 750°C for 1 hour, crystallized at a crystallization temperature of 1040°C for 1 hour, and finally in a temperature range of 800~840°C Annealing...

Embodiment 3

[0073] The weight percentages of glass are:

[0074] SiO 2 : 40%; Al 2 o 3 : 18%; CaO: 14.2%; MgO: 7%; Na 2 O: 5.4%; K 2 O: 4.3%; TiO 2 : 5.6%; Fe 2 o 3 : 5%; Co 2 o 3 : 0.3%; Ni 2 o 3 : 0.2%.

[0075] The preparation method is:

[0076] a) Calculate and accurately weigh according to the composition design formula, use a single-head ball mill, and mix for 15 minutes with a material-to-ball ratio of 1:2 to obtain a uniformly mixed glass batch;

[0077] b) Melt the above-mentioned batch materials in a high-temperature lifting furnace at a temperature of 1520°C for 2 hours to obtain a clear and uniform molten glass;

[0078] c) Pour the above-mentioned uniform glass liquid into a preheated graphite mold for molding to obtain a black glass-ceramic matrix;

[0079] d) Put the above-mentioned matrix glass-ceramic directly into the crystallization furnace, hold at 680°C for 30 minutes for nucleation, hold at 950°C for crystallization for 20 minutes, then hold at 816°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com