Stopcock for injection mould

A technology of injection mold and water stopper, which is applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve the problems of easy water leakage, low use efficiency, difficult to change, etc., and achieves improved efficiency and high use efficiency. , the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be specifically introduced with reference to the drawings and specific embodiments.

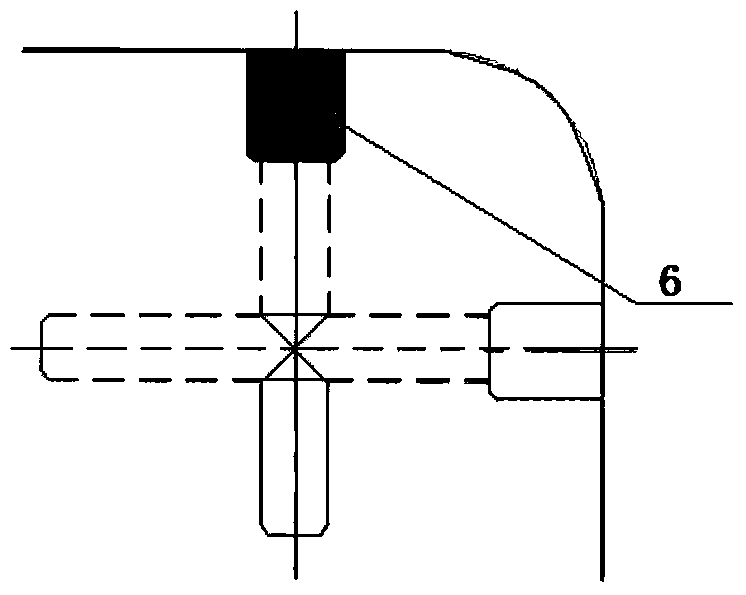

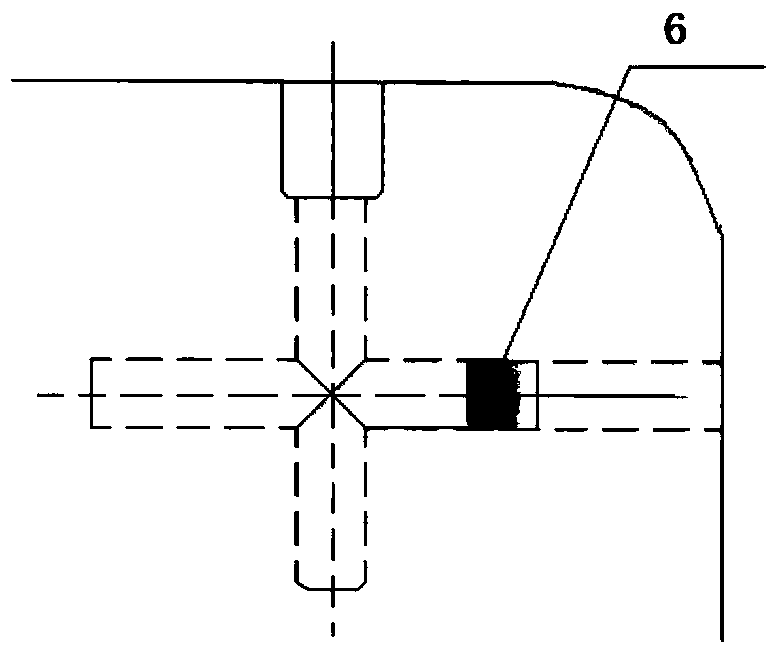

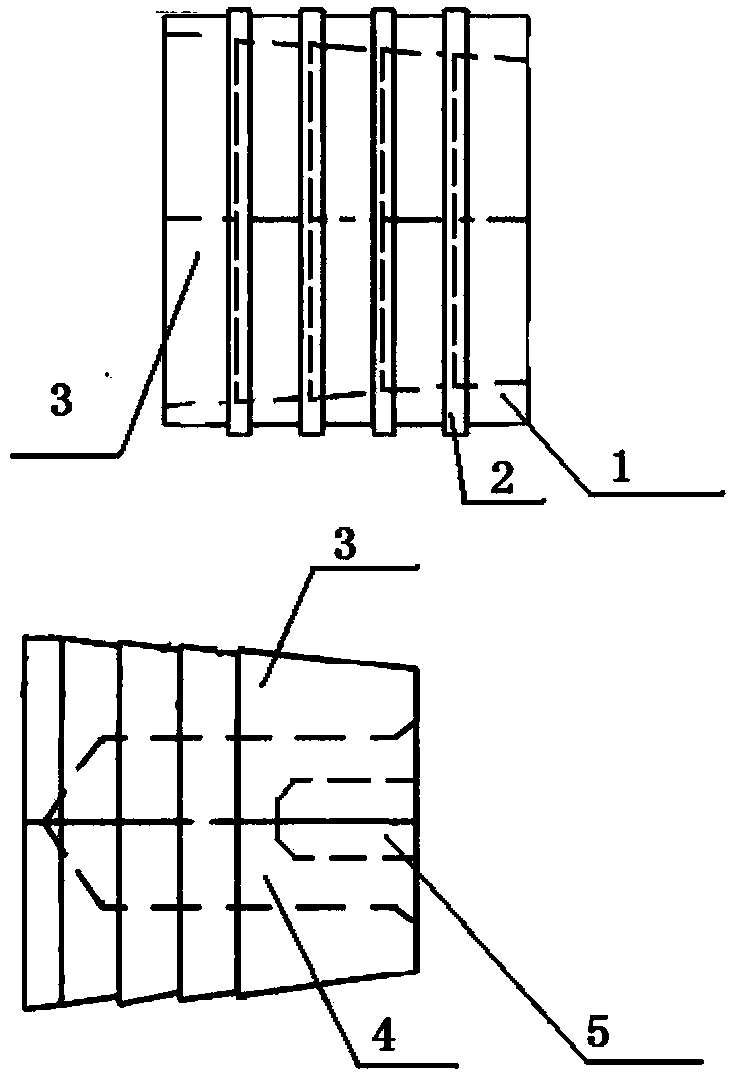

[0020] Combine figure 2 with image 3 , The water stop plug 6 for an injection mold of the present invention includes a brass tube 1 in which a trapezoidal aluminum fastening bolt 3 is provided, and the fastening bolt 3 is connected by 5 trapezoids 4 rubber rings 2 are evenly arranged outside the casing 1, the thickness of the rubber rings 2 is 0.5mm, and each rubber ring 2 is facing the lower bottom of each trapezoid in the fastening bolt 3. On the edge, when the high temperature expands, the expansion of the lower bottom can drive the further expansion of the rubber ring 2. The fastening bolt 3 is provided with an expansion screw 4, and the expansion screw 4 is provided with a groove 5 made of rubber material. The top of the groove 5 is provided with a rectangular opening (not shown in the figure), which can be used with a water stop plug instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com