Machining method of TC4 titanium alloy thick-wall tubular product

A processing method, a technology of titanium alloy pipes, applied in the field of forging processing of alloy materials, can solve the problems of small pipe specification span and low efficiency, and achieve the effect of uniform structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

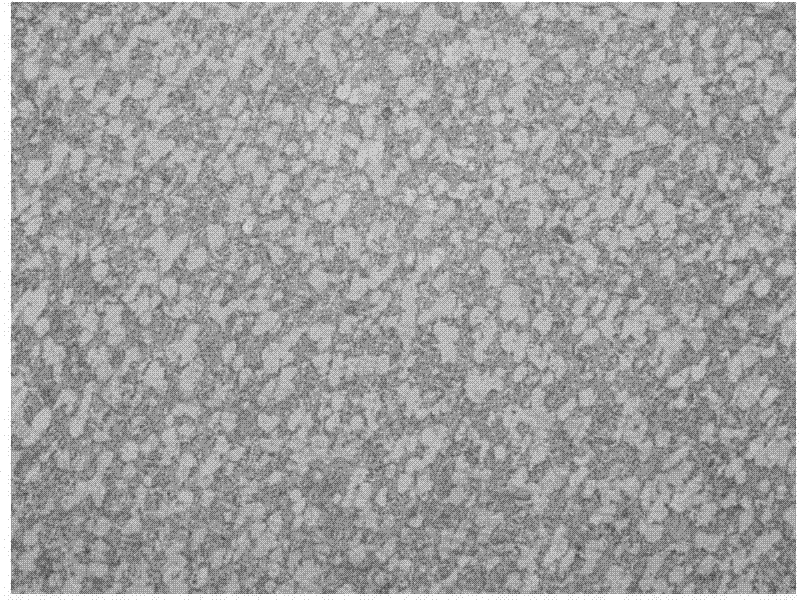

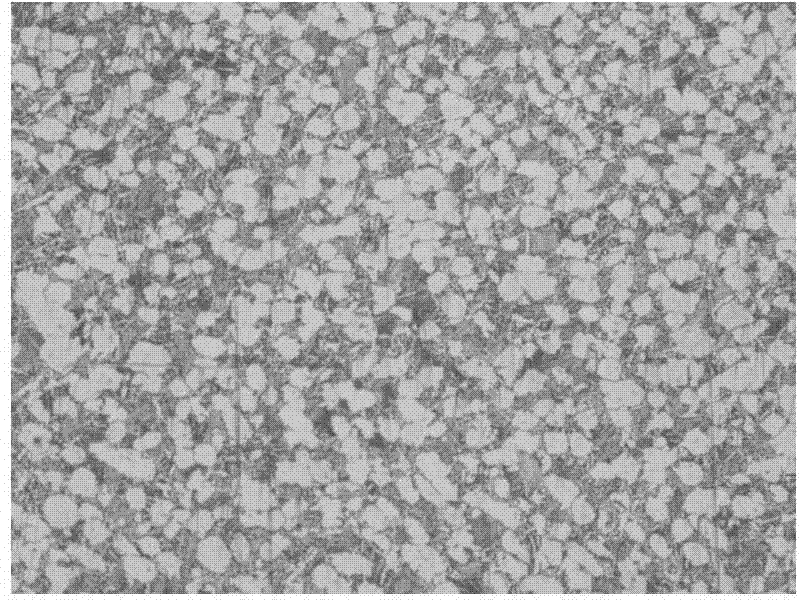

Image

Examples

Embodiment 1

[0034] The material processed in Example 1 is a titanium alloy tube blank with an ingot number of 534-20130121, with an outer diameter of Φ220 mm and an inner diameter of Φ120 mm. According to the processing method of the present invention, through forging and heat treatment, the pipe material with an outer diameter of Φ150mm and an inner diameter of Φ100mm is produced.

[0035] Step 1 Heating: Heating with an electric furnace, heating the selected titanium alloy tube billet to 980°C, holding it for 90 minutes and then out of the furnace for forging;

[0036] Step 2 forging: forging the tube blank heated in step 1 with a precision forging machine, the forging ratio is 0.5-1.0, the final forging temperature is 750°C, and the total forging ratio is 2.0;

[0037] Step 3 heat treatment: heat the pipe forged in step 2 to 780°C, keep it warm for 2 hours, then take the pipe out of the electric furnace and put it in the fan area for wind cooling within 20 seconds;

[0038] Step 4 Str...

Embodiment 2

[0049] The material processed in Example 2 is a tube blank with an ingot number of 534-20130233, with an outer diameter of Φ180 mm and an inner diameter of Φ90 mm. According to the processing method of the present invention, through forging and heat treatment, the pipe material with an outer diameter of Φ100mm and an inner diameter of Φ70mm is produced.

[0050] Step 1 Heating: Heating with an electric furnace, heating the selected titanium alloy tube billet to 960°C, holding it for 70 minutes and then out of the furnace for forging;

[0051] Step 2 forging: Forging the tube blank heated in step 2 with a precision forging machine, the forging ratio is 0.8-1.2, the final forging temperature is 750°C, and the total forging ratio is 3.0;

[0052] Step 3 heat treatment: heat the pipe forged in step 2 to 780°C, keep it warm for 2 hours, then take the pipe out of the electric furnace and put it into the fan area for wind cooling within 20 seconds;

[0053] Step 4 Straightening: Str...

Embodiment 3

[0063] The material processed in Example 3 is a titanium alloy tube blank with an ingot number of 534-20130345, with an outer diameter of Φ140 mm and an inner diameter of Φ70 mm. According to the processing method of the present invention, through forging and heat treatment, the pipe material with an outer diameter of Φ90mm and an inner diameter of Φ60mm is produced.

[0064]Step 1 Heating: use an electric furnace to heat, heat the selected titanium alloy tube billet to 950°C, keep it warm for 60 minutes and take it out of the furnace for forging;

[0065] Step 2 forging: forging the tube blank heated in step 1 with a precision forging machine, the forging ratio is 0.5-1.0, the final forging temperature is 750°C, and the total forging ratio is 2.3;

[0066] Step 3 heat treatment: heat the pipe forged in step 2 to 750°C, keep it warm for 1.5h, then take the pipe out of the electric furnace and put it into the fan area for wind cooling within 20 seconds;

[0067] Step 4 Straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com