Aqueous dispersion of blocked polyisocyanate, fiber treatment agent composition and fabric

A technology of polyisocyanate and diisocyanate, applied in the field of water dispersion of blocked polyisocyanate, can solve problems such as water repellency reduction, and achieve the effects of excellent mechanical stability, good water dispersion stability and high coating film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

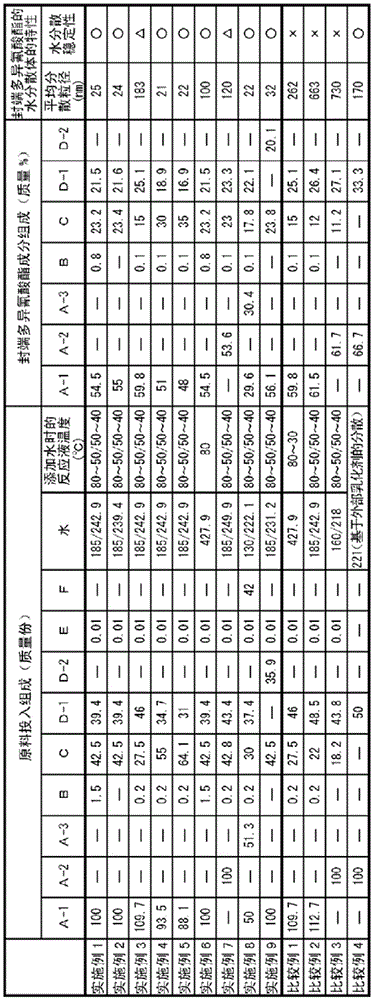

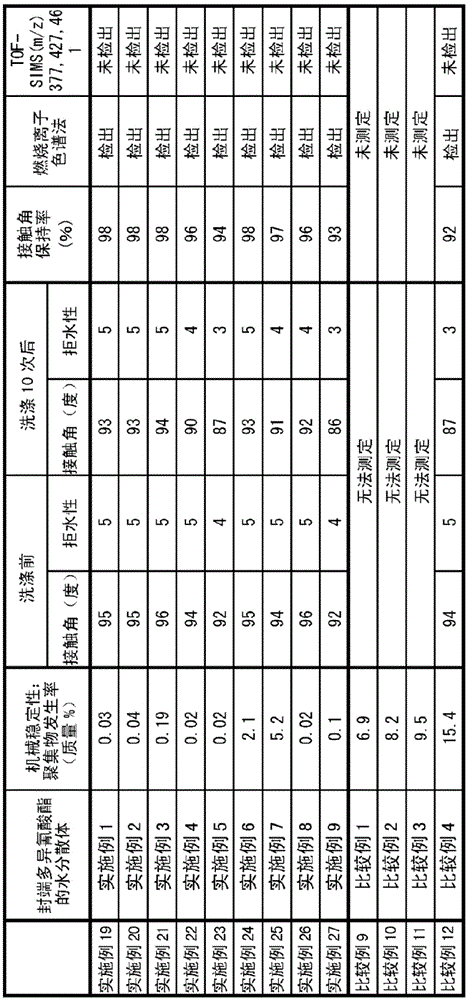

Examples

Embodiment

[0149] Although the present invention will be specifically described with reference to the following examples and the like, the present invention is not limited thereto.

[0150] (1) Viscosity determination:

[0151] The viscosity was measured using the following device.

[0152] Device: RE-80R (manufactured by Toki Sangyo Co., Ltd.)

[0153] Rotor: cone plate 1°34'×R24

[0154] Measuring temperature: 25°C

[0155] (2) Determination of number average molecular weight:

[0156] The number average molecular weight is a polystyrene standard number average molecular weight measured by gel permeation chromatography using the following apparatus.

[0157] Device: HLC-802A (manufactured by Tosoh Corporation)

[0158] Column: G1000HXL×1 (manufactured by Tosoh Corporation)

[0159] G2000HXL×1 (manufactured by Tosoh Corporation)

[0160] G3000HXL×1 (manufactured by Tosoh Corporation)

[0161] Carrier gas: tetrahydrofuran

[0162] Flow rate: 0.6mL / min

[0163] Sample concentrat...

manufacture example 1

[0221] (Production example 1: Production of polyisocyanate)

[0222] A 4-neck flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen blowing pipe was made into a nitrogen atmosphere, and 1000 parts by mass of HDI and 22 parts by mass of trimethylolpropane (molecular weight: 134) as a trihydric alcohol were added, and stirred The temperature in the reactor was maintained at 90° C. for 1 hour to perform urethanization. Thereafter, the temperature of the reaction solution was kept at 60° C., an isocyanuration catalyst tetramethylammonium caprylate was added, and when the conversion rate reached 48%, phosphoric acid was added to stop the reaction. Thereafter, after filtering the reaction liquid, unreacted HDI was removed by a thin film distillation apparatus.

[0223] The obtained polyisocyanate had a viscosity at 25° C. of 25,000 mPa·s, an isocyanate group content of 19.9% by mass, a number average molecular weight of 1080, and an isocyanate average f...

manufacture example 2

[0224] (Production example 2: Production of polyisocyanate)

[0225] A nitrogen atmosphere was made in a 4-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen blowing pipe, and a dropping funnel, and 1000 parts by mass of HDI was put in, and the temperature in the reactor was kept at 70° C. under stirring. An isocyanurate catalyst tetramethylammonium octanoate was added, and when the yield reached 40%, phosphoric acid was added to stop the reaction. After filtering the reaction solution, unreacted HDI was removed using a thin film evaporator.

[0226] The viscosity of the obtained polyisocyanate at 25°C was 2700 mPa·s, the content of isocyanate was 21.7%, the number average molecular weight was 660, and the average number of functional groups of isocyanate was 3.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com