Intermediate film for laminated glass, and laminated glass

A technology of laminated glass and interlayer film, applied in glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problem of large infrared thermal effect, and achieve the effect of improving transmittance and heat insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

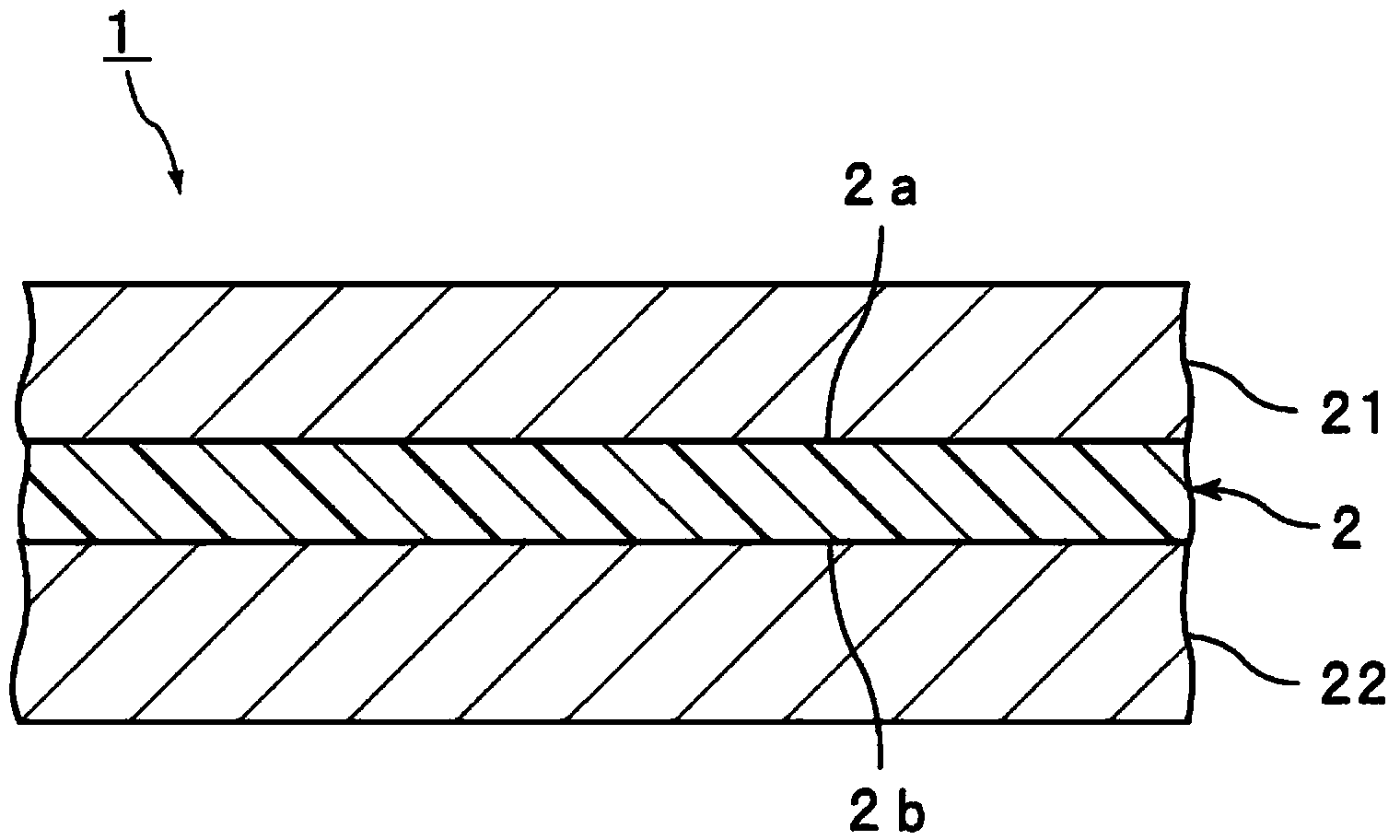

[0193] (1) Production of interlayer film

[0194] Prepare a 0.19% by weight ethanol solution containing magnesium bis(2-ethylbutyrate) metal salt in an amount of 0.067% by weight in 100% by weight of the obtained interlayer film %.

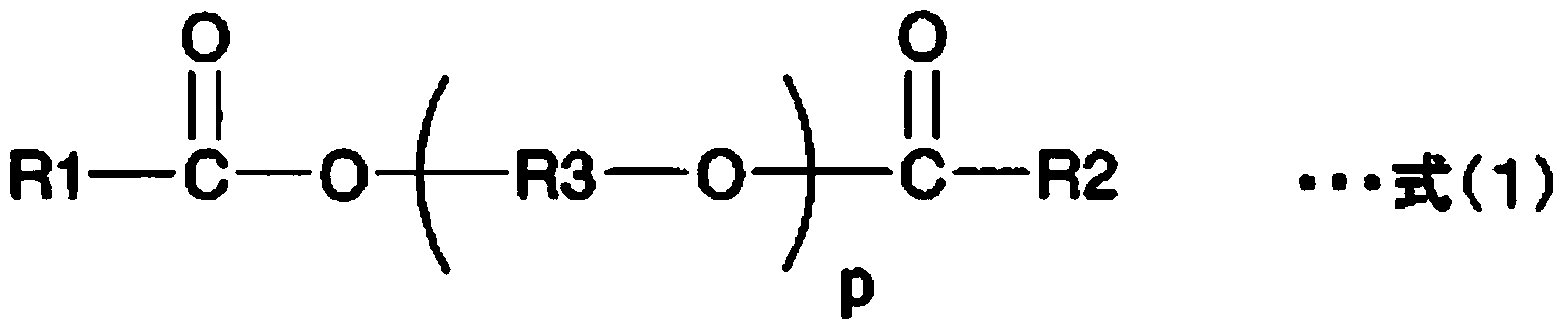

[0195] Mix 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) with the following materials: CWO particles, so that their amount in the obtained intermediate film 100% by weight is 0.035% by weight; ITO particles , so that its amount in 100% by weight of the obtained interlayer film is 0.14% by weight; a phthalocyanine compound, so that its amount in the obtained interlayer film is 0.004% by weight; After the phosphoric acid ester compound was mixed with a horizontal micro-bead mill, a dispersion was obtained. It should be noted that the content of the phosphate compound was adjusted to be 1 / 10 of the total content of the CWO particles and the ITO particles.

[0196] Add the following substances relative to 100 parts by weight of...

Embodiment 2~10 and comparative example 1~9

[0203] A single-layer interlayer film was produced in the same manner as in Example 1 except that the types and contents of the compounding components were set as shown in Tables 1 and 2 below. The types and compounding amounts of the same polyvinyl butyral resin and plasticizer as in Example 1 were set. Using the obtained interlayer film, laminated glasses A and B including the interlayer film were produced in the same manner as in Example 1.

[0204] In addition, in Comparative Example 7, when compounding the heat ray shielding agent, lanthanum hexaboride particles were compounded so that the amount in the obtained interlayer film was 0.007% by weight. In Comparative Example 8, gallium-doped zinc oxide particles were blended so that the amount in the obtained interlayer film was 0.120% by weight when blending the heat ray shielding agent. In Comparative Example 9, when blending the heat ray shielding agent, an imonium compound ("CIR-RL" manufactured by Nippon Carlit Co., Lt...

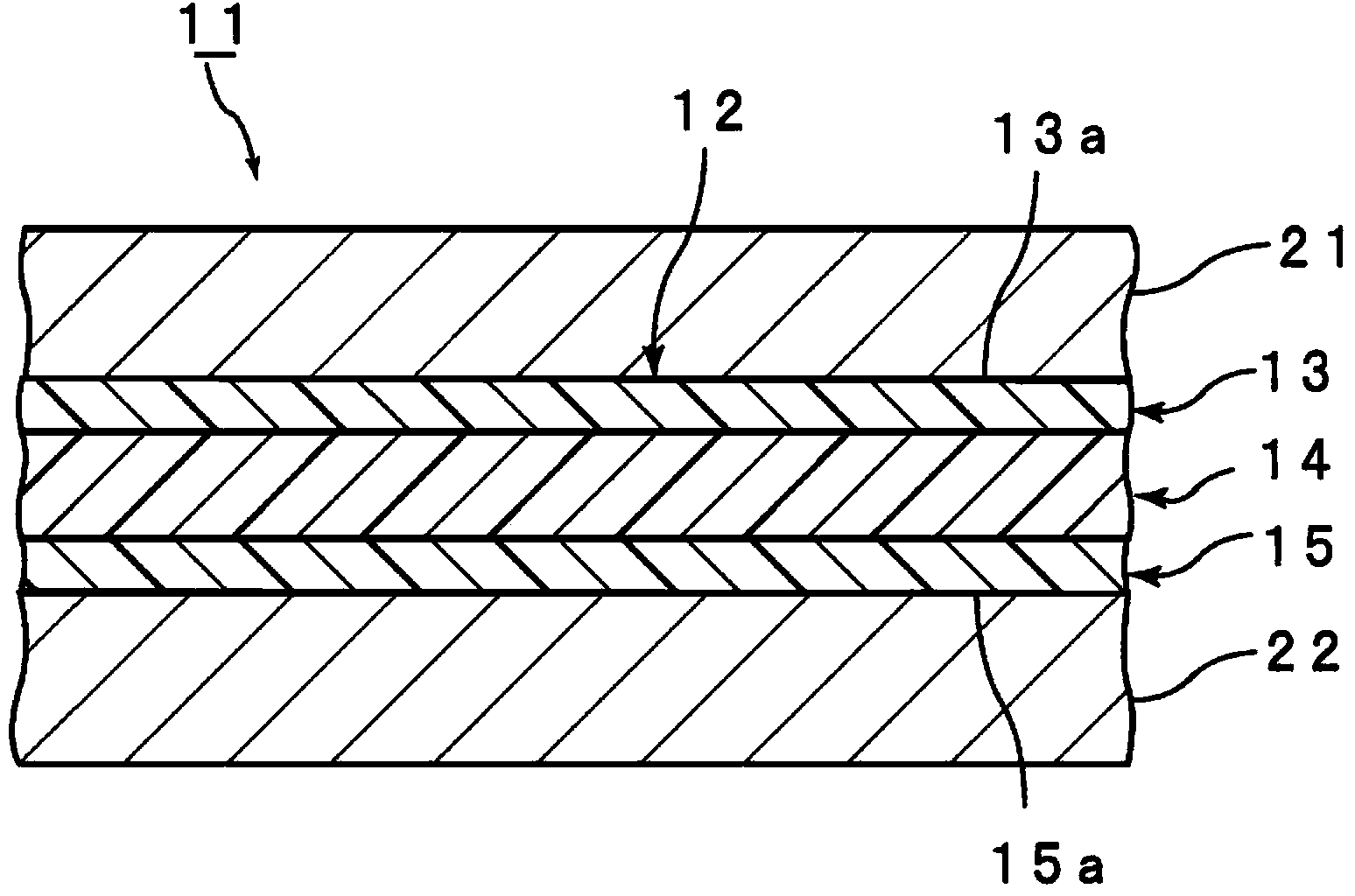

Embodiment 11

[0206] (1) Preparation of the first composition for forming the intermediate layer

[0207] Add 60 parts by weight of plasticizer triethylene glycol di-2-ethylhexanoate relative to 100 parts by weight of polyvinyl butyral resin (PVB2), and fully knead with mixing rollers to obtain The first composition of the middle layer.

[0208] (2) Preparation of the second composition for forming the surface layer

[0209] Prepare a 0.19% by weight ethanol solution containing magnesium bis(2-ethylbutyrate) metal salt in an amount of 0.067% by weight in 100% by weight of the obtained interlayer film %.

[0210]Mix 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) with the following materials: CWO particles, so that their amount in the obtained intermediate film 100% by weight is 0.026% by weight; ITO particles , so that its amount in 100% by weight of the intermediate film obtained is 0.127% by weight; a phthalocyanine compound, such that its amount in the obtained inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com