A semiconductor laser with high power and high beam quality laser

A semiconductor and high-beam technology, which is applied to the device for controlling the output parameters of the laser, the structure of the optical resonator, etc., can solve the problems of affecting the quality of the laser beam, the ineffective application, and the deterioration of the beam quality, so as to expand the application range and reduce the size of the laser beam. Spot, improve the effect of the mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

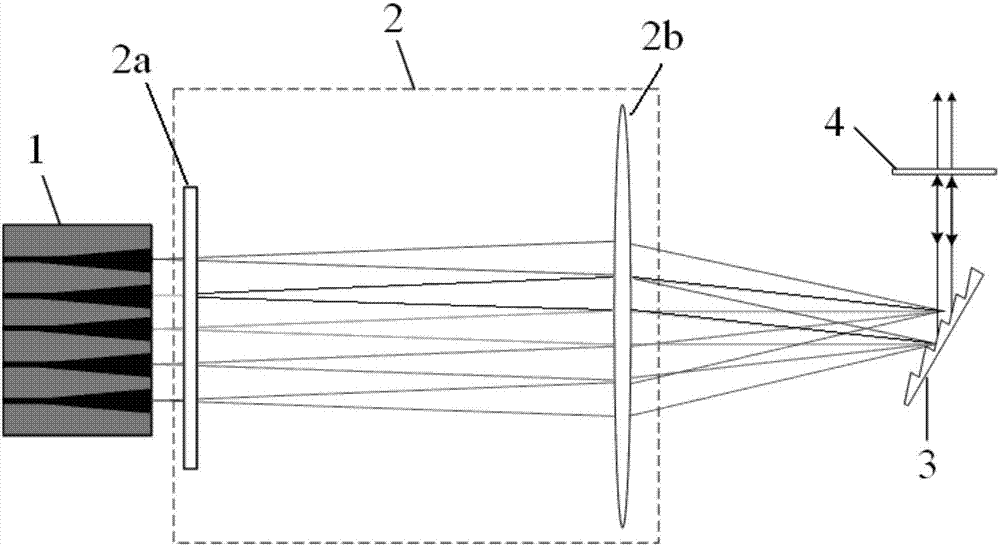

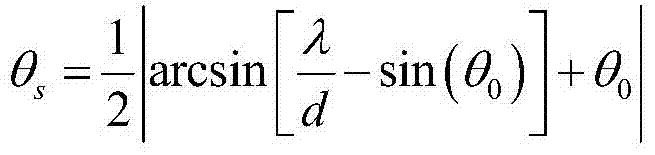

[0023] figure 1 The structure and optical path of a semiconductor laser with high power and high beam quality laser according to the embodiment of the present invention are shown. In this embodiment, the semiconductor gain medium is (InGa)(AsP) / InP, and its semiconductor gain element 1 contains 19 active gain regions, each of which is cone-shaped to reduce its The transverse mode of the output laser results in better beam quality. The rear surface is coated with a high reflectance film to 940nm±5nm, and the front surface is coated with a high transmittance film to 940nm±5nm. The coupling output mirror 4' is a concave mirror coated with a film with a transmittance of 80%. The light beam emitted by the active gain area passes through the cylindrical lens 2a and the spherical lens 2b to collimate the fast axis and the slow axis respectively, and then is collimated by the spherical lens 2b. Focused on the blazed grating 3, after being reflected, the light beam is partially trans...

Embodiment 2

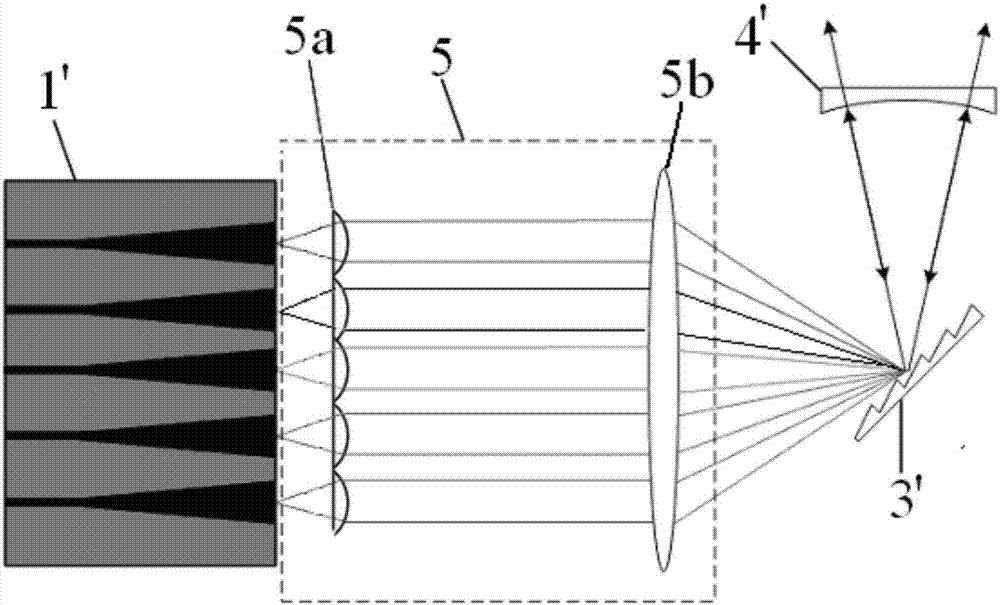

[0028] figure 2 It shows the structure and optical path of the semiconductor laser with high power and high beam quality laser in the second embodiment of the present invention. In this embodiment, the semiconductor gain medium is (InGa)(AsP) / InP, and its semiconductor gain element 1' contains 19 active gain regions, and each active gain region is conical in shape to reduce It outputs the transverse mode of the laser light, resulting in better beam quality. The rear surface is coated with a high reflectance film to 940nm±5nm, and the front surface is coated with a high transmittance film to 940nm±5nm. The coupling output mirror 4 is a flat mirror coated with a film with a transmittance of 80%. The light beam emitted by the active gain area is collimated by the microlens 5a, focused by the spherical lens 5b and irradiated onto the blazed grating 3', and then coupled The output mirror 4' partly transmits the output and partly feeds back the oscillation. If the first-order di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com