A kind of thin rod two-way internal force measurement sensor and calibration method

A technology for measuring sensors and thin rods, applied in the direction of measuring force, force/torque/work measuring instrument calibration/testing, measuring devices, etc., can solve the problems of high precision, wide versatility, high stability, and achieve accurate non-destructive measurement High degree of versatility and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

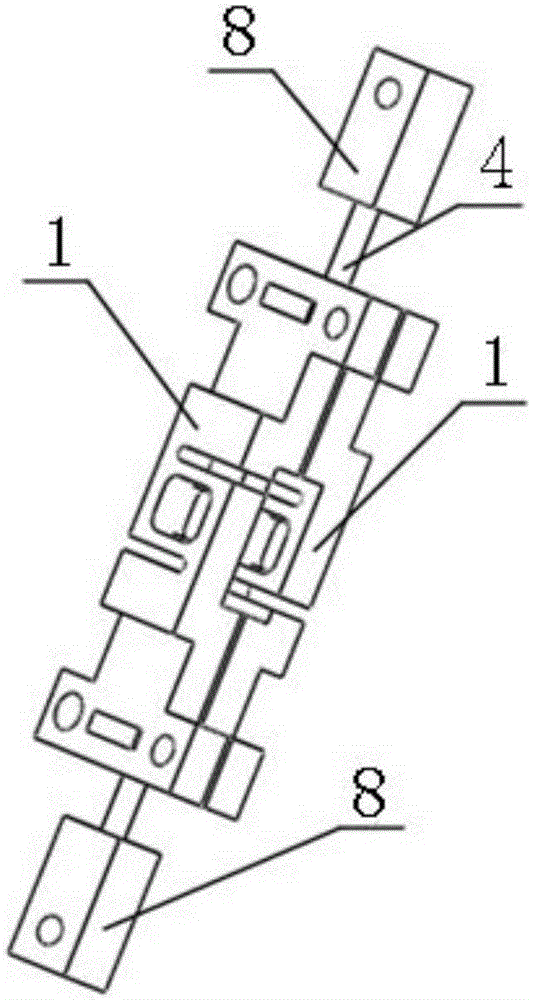

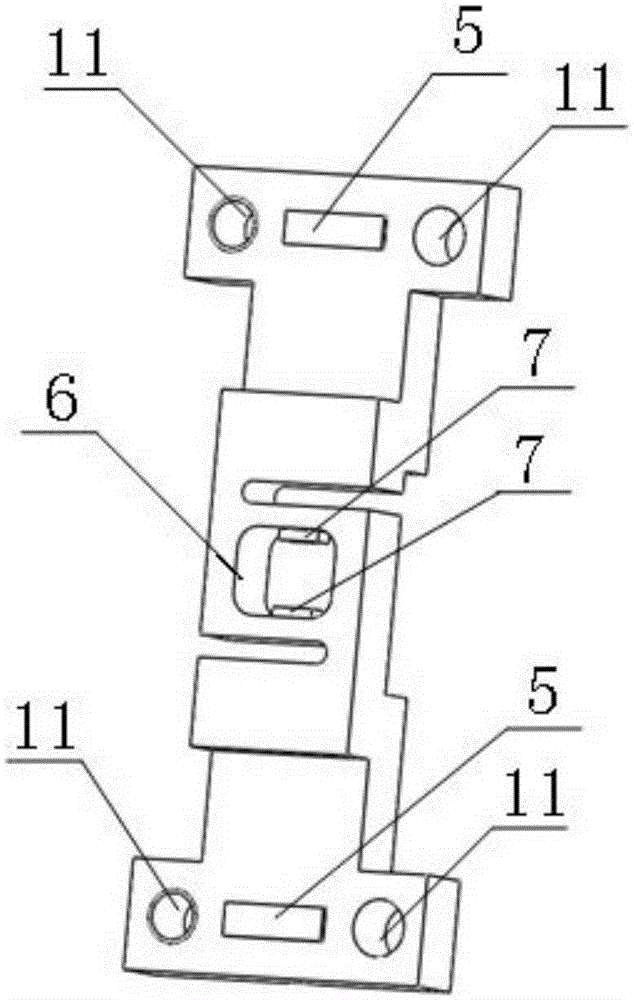

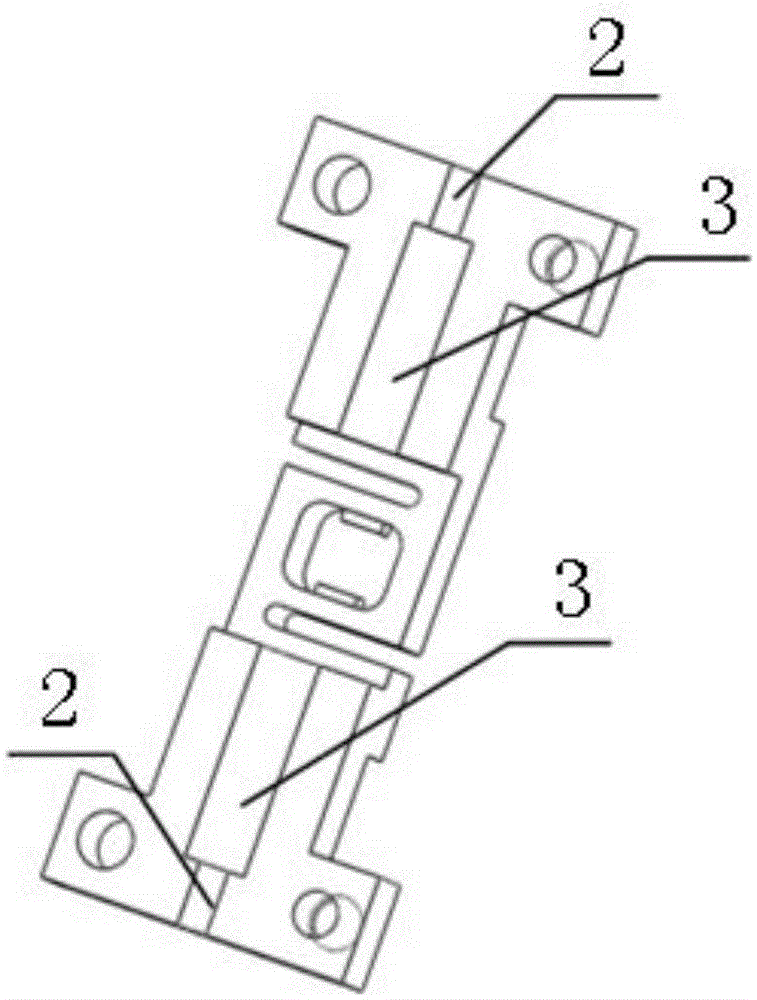

[0022] Such as Figure 1 to Figure 3 As shown, a thin-rod two-way internal force measurement sensor includes two identical symmetrically arranged splints 1, four mounting holes 11 are respectively arranged on the two splints 1, bolts are arranged in the mounting holes 11, and each splint 1 There are 2 card slots 2 and 2 grooves 3 on the back, such as image 3 As shown, the card slot 2 and the groove 3 are on a straight line, and the groove 3 is located between the two card slots 2, the card slot 2 is adapted to the thin rod 4, and the size of the groove 3 is relatively large. The thin rod 4 is stuck in the two card slots 2, and the rod body between the two card slots 2 passes through the groove 3 without contacting the groove 3; the two splints 1 are connected back to back by bolts Fixed together, the distance between the two splints 1 can be adjusted by changing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com