Four side return air side directional air supply air source heat pump system

A heat pump system and side return technology, which is applied in the operation mode of the machine, the combination of heating and cooling, lighting and heating equipment, etc., can solve the problems of deteriorating the working environment of the air source host, inability to save energy, and reducing work efficiency. Achieve the effect of reducing material consumption, compact structure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

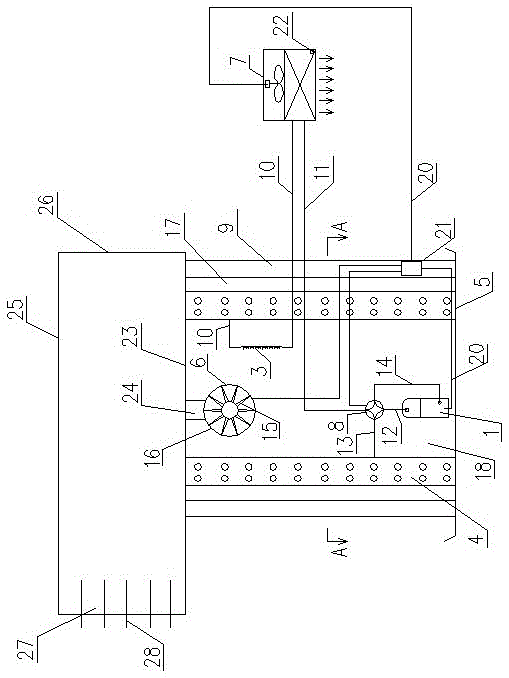

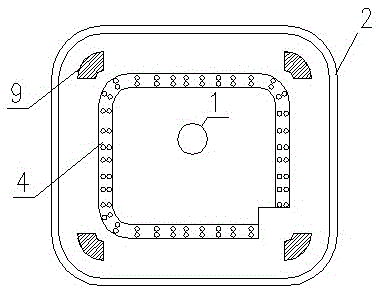

[0022] The air source heat pump system of the four side air return and side directional air supply in this embodiment is as follows: figure 1 As shown, it includes an outdoor unit and an indoor unit. The outdoor unit is divided into an outer chamber 17 and an inner chamber 18 by a heat exchanger 4. The outer chamber 17 is surrounded by a part of the heat exchanger 4 and the shell 2. The outer chamber 17 communicates with the atmosphere. , the inner chamber 18 is composed of a heat exchanger 4, a base plate 5, an edge-sealing cover plate 31 connecting the two ends of the heat exchanger 4, a centrifugal fan 6, and a volute plate 23 for installing the centrifugal fan 6, and the centrifugal fan 6 is installed inside In the chamber 18, the centrifugal fan 6 is composed of a volute 16, blades and its motor assembly 15. The static pressure chamber 26 communicates with the inner chamber 18, and the outer side of the static pressure chamber is provided with a main engine air outlet 27, ...

Embodiment 2

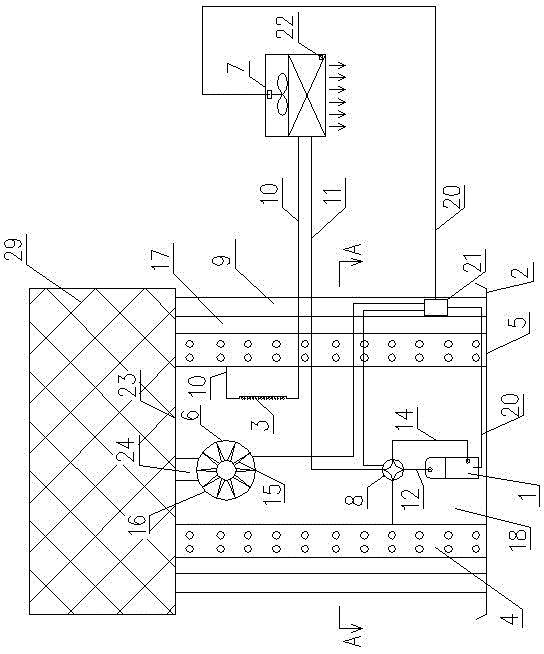

[0025]In Embodiment 2, the guide vane assembly is changed to an anti-foreign matter intrusion net 29 at the air outlet, and the others are the same as Embodiment 1.

Embodiment 3

[0027] In embodiment 3, the air outlet is changed to a plurality of circular jet holes 30, and the others are the same as in embodiment 1.

[0028] The use method of the present invention is as follows: before use, turn on the power supply, set the operation mode and temperature parameters. At this time, the whole system will automatically work according to the setting to realize energy-saving operation.

[0029] The indoor part of the present invention can also be in the form of conventional fan coil units, air duct machines, floor heating and cooling tube bundles, floor heating tube bundles and indoor surface coolers for cooling and heating supply, etc. The change of the form of the indoor terminal, the change of the layout of the outdoor cavity, the air outlet of the main engine from one side or multiple sides, the change of the form of the air outlet, the change of the form and length of the guide vane, etc. are all covered by the present invention. Technical coverage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com