Cam shaft oil pressure seal end cover

A technology for sealing end caps and camshafts, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of reduced reliability, the baffle structure occupies space, and the engine installation is difficult to coordinate, etc., and achieves reliable sealing structure. Solve the probability of plastic deformation coming out of the mounting hole and eliminate the effect of the disengagement failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

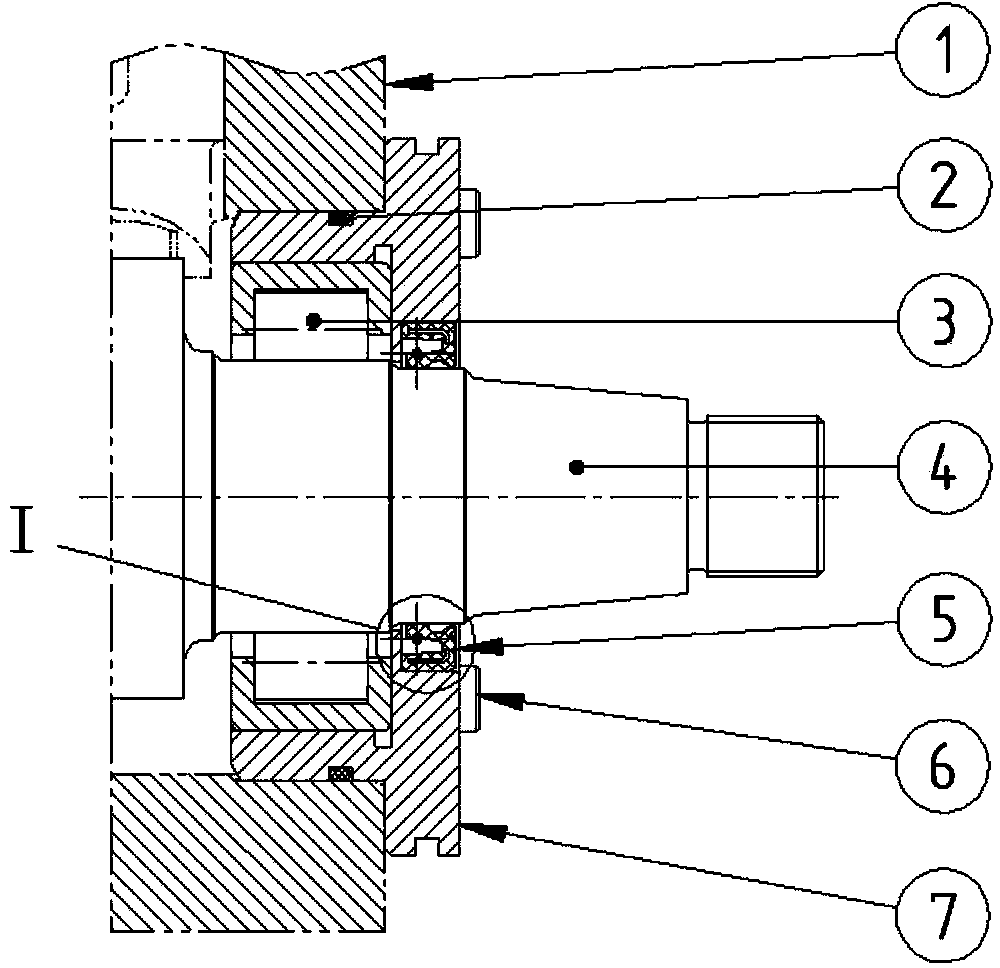

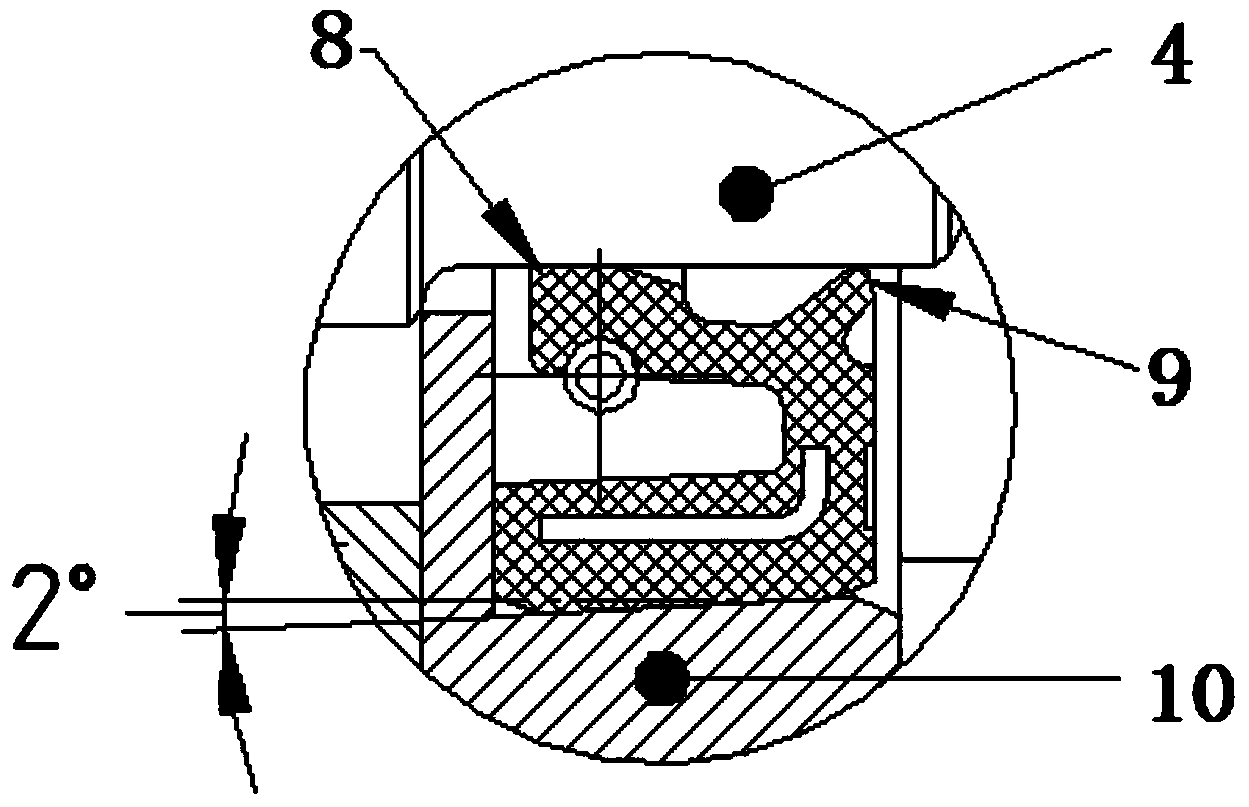

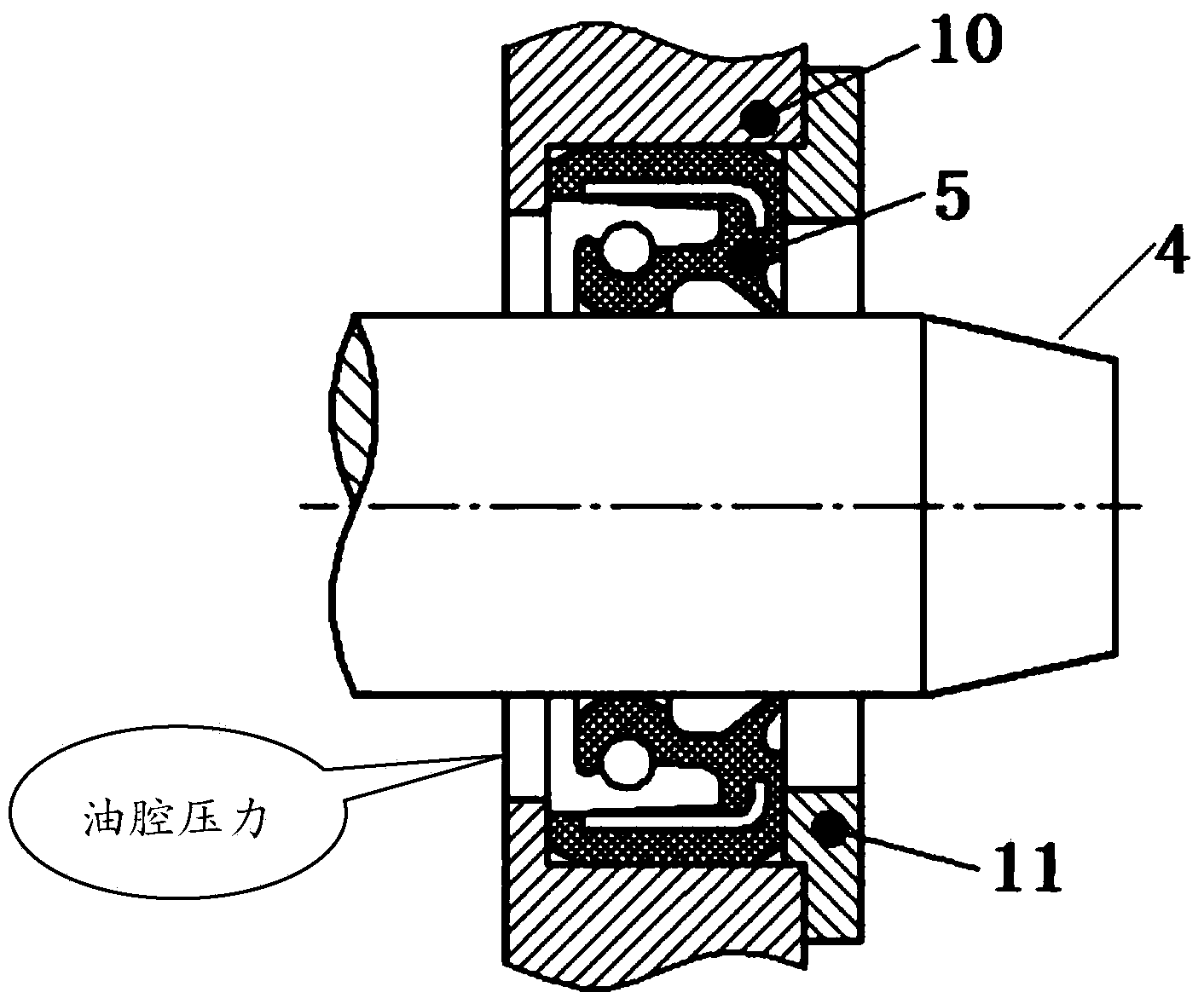

[0015] exist figure 1 Among them, the camshaft oil pressure seal end cover includes the end cover body 7 assembled on the power input end of the camshaft and fixedly connected to the end face of the oil storage cavity of the pump box 1, and the skeleton frame lip that hugs the camshaft tightly to prevent oil leakage. Labyrinth seal ring 5. The end cover body 7 is fixedly connected to the pump box 1 by screws 6 . A roller bearing without an inner ring 3 passing through the camshaft is installed in the inner stepped hole of the end cover body 7 . The roller bearing 3 without an inner ring is used to support the camshaft 4, and the main lip 8 and the auxiliary lip 9 of the skeleton lip-shaped labyrinth seal ring 5 tightly hug the journal of the camshaft 4 to form a sealing band. The mounting seat hole of the skeleton lip labyrinth seal ring on the end cover body 7 is a tapered hole with a large inside and a small outside, forming an inverted cone anti-extraction structure great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com