Hydraulic manual drill

A manual drilling and hydraulic technology, which is applied in earthwork drilling, drilling equipment, percussion drilling, etc., can solve the problems of unusable, heavy equipment, labor-intensive, etc., reduce limitations, reduce equipped personnel, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

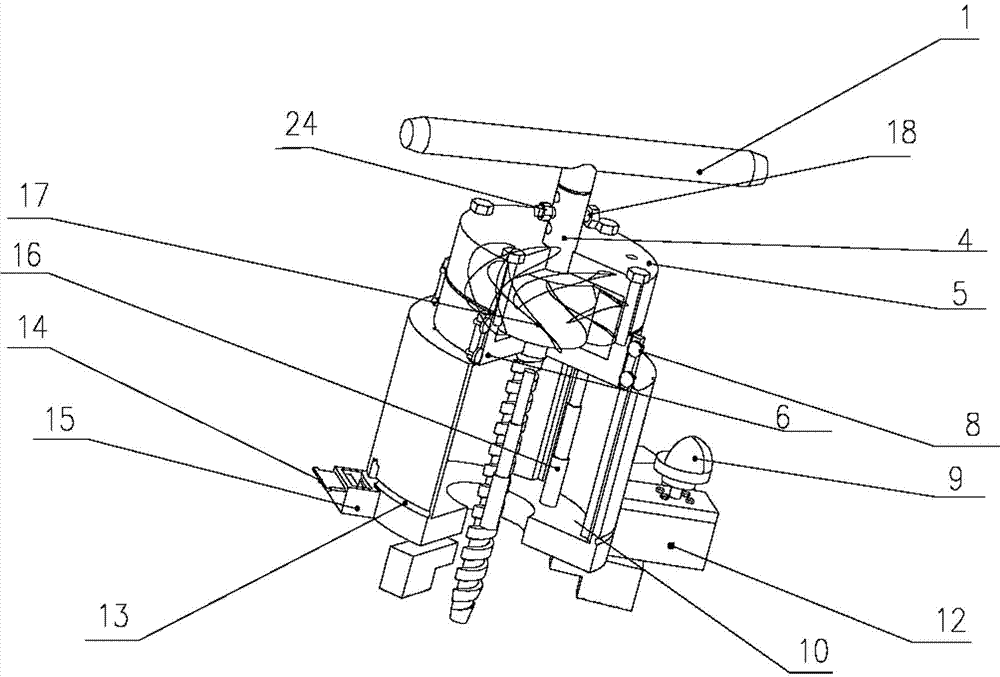

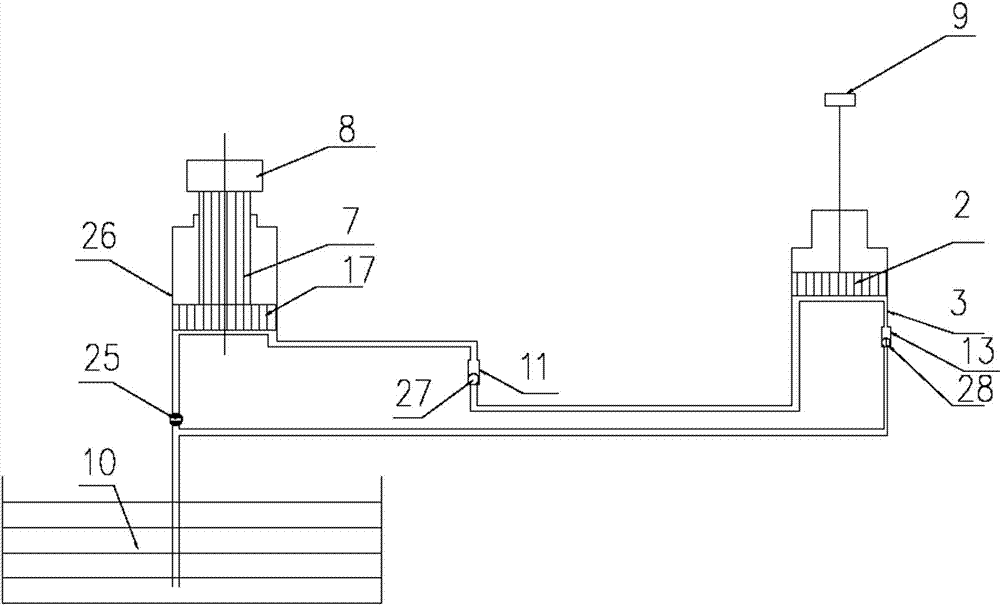

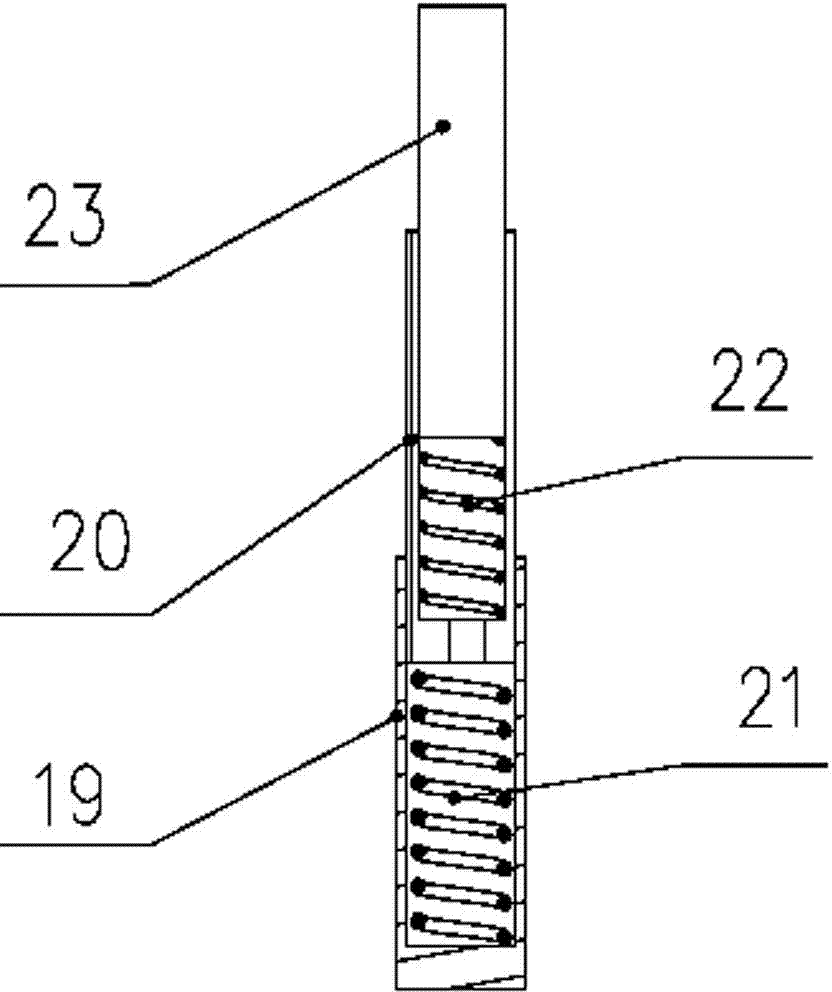

[0015] See attached Figure 1-2 As shown, a hydraulic manual drill comprises a drill rod 4, the lower end of the drill rod is a threaded structure, the upper end of the drill rod is a polished rod structure, the upper end of the drill rod is provided with a hand handle 1, and the outer side of the drill rod is provided with a lower box. body 10, the thread structure section protrudes from the lower box body, the drill rod polished rod structure section is provided with an upper box body, the upper box body is sealed by the upper box body top cover 5 and the upper box body bottom cover 6, and the polished rod structure section is provided with a turbine Leaf 17, the inner side of the upper box body and the inner side of the lower box body realize the movement of the upper part to the lower part through the roller 8, the outer side of the lower box body is provided with a foot 12, the foot is provided with a foot pedal 9, and the foot pedal is connected to the hydraulic system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com