A kind of high-impact polystyrene-modified stress-whitening-resistant polypropylene composite and preparation method thereof

A technology of polystyrene and polystyrene resin, applied in the field of polystyrene-modified stress-whitening-resistant polypropylene compound and its preparation, can solve the problem of unsatisfactory stress-whitening resistance and poor stress-whitening resistance Prominent, high dosage of copolymerized polypropylene, etc., to achieve the effect of low cost, not easy to peel off, and increase toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

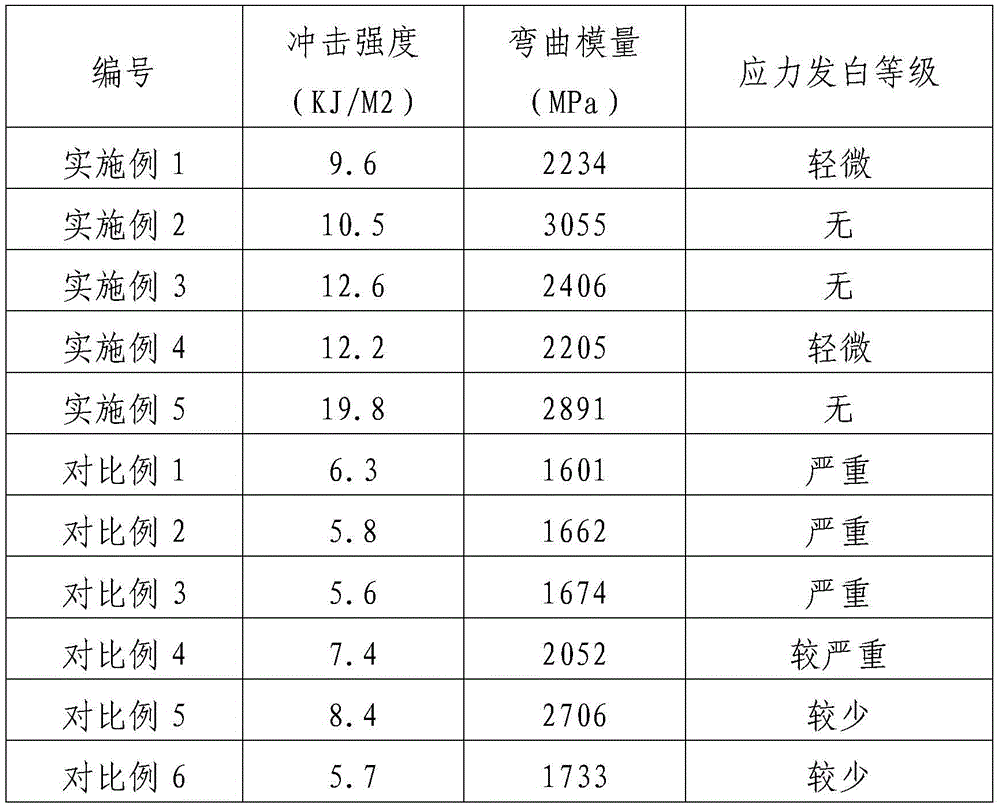

Examples

Embodiment 1

[0028] (1) Preparation of high impact polystyrene masterbatch

[0029] 38 parts by weight of polystyrene resin, 55 parts by weight of polypropylene resin, 7 parts by weight of SEBS grafted maleic anhydride (melt index of 2g / 10min, grafting rate of 0.8%) and 0.4 parts of processing aid stearic acid The calcium is uniformly mixed, extruded and granulated by a screw extruder, and the processing temperature of the extruder is 190-230°C.

[0030] (2) Preparation of filler masterbatch

[0031] 28 parts by weight of polypropylene resin, 60 parts by weight of talcum powder inorganic filler (average particle size is 5 microns), 8 parts by weight of aminosilane coupling agent, 10 parts by weight of polypropylene grafted maleic anhydride (melt index is 80g / 10min, grafting rate of 0.8%) and 0.4 parts by weight of zinc stearate are evenly mixed, melt-extruded and granulated through a screw extruder, and the processing temperature of the extruder is 190-230°C.

[0032] (3) Preparation of ...

Embodiment 2

[0043] (1) Preparation of polystyrene masterbatch

[0044] Mix 40 parts by weight of polystyrene resin, 53 parts by weight of polypropylene resin, 7 parts by weight of SEBS grafted acrylic acid (melt index of 2g / 10min, grafting rate of 0.8%) and 0.4 parts by weight of zinc stearate , Extruded and granulated by a screw extruder, the processing temperature of the extruder is 190-230°C.

[0045] (2) Preparation of filler masterbatch

[0046] 30 parts by weight of polypropylene resin, 60 parts by weight of talcum powder inorganic filler (average particle diameter is 5 microns), 10 parts by weight of epoxy silane coupling agent, 10 parts by weight of polypropylene grafted maleic anhydride (melt index (80g / 10min, graft rate 0.8%) and 0.3 parts by weight of calcium stearate are uniformly mixed, melted and extruded to form pellets through a screw extruder, and the processing temperature of the extruder is 190-230°C.

[0047] (3) Preparation of high-impact polystyrene modified stress...

Embodiment 3

[0058] (1) The preparation of polystyrene masterbatch and filler masterbatch is the same as in Example 1.

[0059] (2) Preparation of high-impact polystyrene modified stress-whitening polypropylene composites:

[0060] Take each substrate component by the following parts by weight:

[0061] 45 parts by weight of polypropylene resin

[0062] 20 parts by weight of polystyrene masterbatch

[0063] 30 parts by weight of filler masterbatch

[0064] 5 parts by weight of chain segment binding agent dicumyl oxide

[0065] 0.2 parts by weight of antioxidant 1010

[0066] The processing aid zinc stearate of 0.2 weight part;

[0067] Its preparation process is as follows:

[0068] After the components weighed above are mixed evenly, they are added to a twin-screw extruder for extrusion. The temperature of the extruder is set at 210°C and the speed is 300rpm; the extruded product is cooled by water and pelletized to obtain High impact polystyrene modified stress whitening polypropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com