Fully-automatic polishing machine

A polishing machine, fully automatic technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as inability to form batch processing, insufficient overall structure, and unfavorable mass processing , to achieve the effect of smooth polishing, strong practicability, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

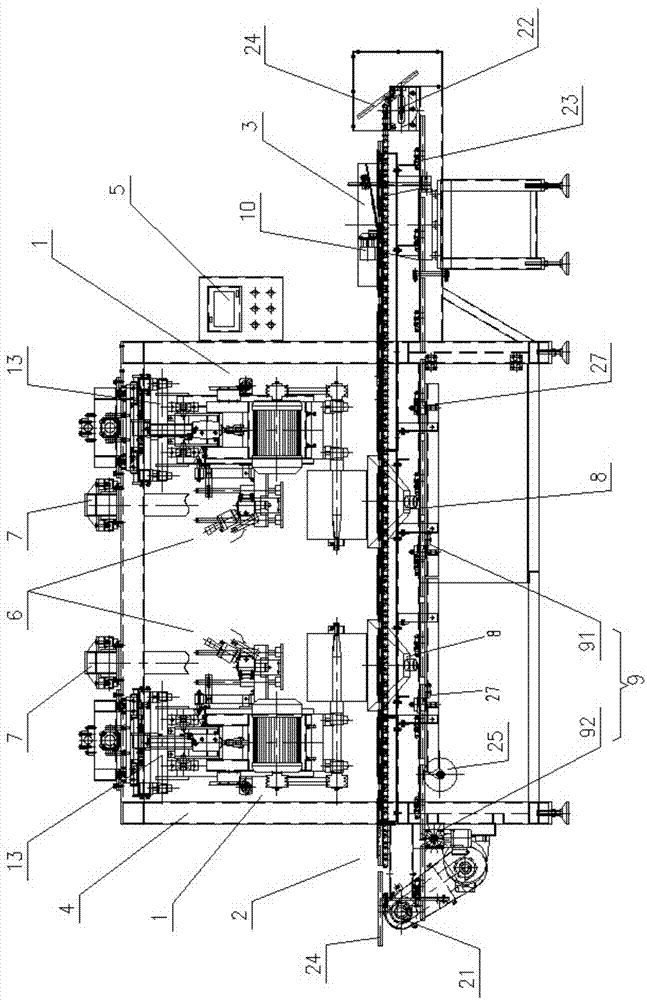

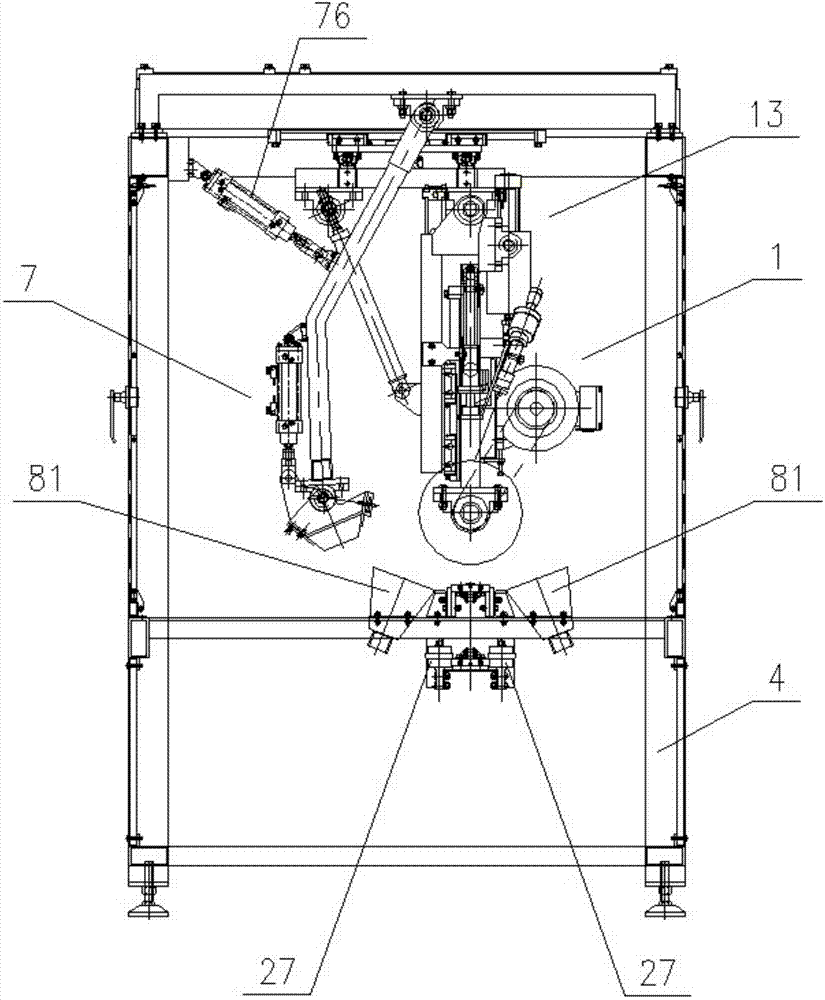

[0085] A kind of automatic polishing machine of the present invention, as Figure 1-16 As shown, it includes a polishing mechanism 1, a feeding mechanism 2, a feeding mechanism 3, a frame 4, and a controller 5 that is connected to the first three.

[0086]The polishing mechanism 1 comprises a polishing wheel 11, a rotary driving device 12 for rotating the polishing wheel 11, and a space motion mechanism 13 which carries the polishing wheel 11 and the rotary driving device 12 and is arranged on the frame 4, the rotary driving device 12 and the space The motion mechanism 13 is controlled and connected with the controller 5; the feeding mechanism 2 includes a conveying chain 23 which is arranged on the frame 4 through a drive sprocket (equipped with a power motor) 21 and a driven sprocket 22, and a plurality of On the material receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com