Washing device used for chemical mechanical polishing equipment

A cleaning device and chemical-mechanical technology, used in grinding/polishing equipment, grinding/polishing safety devices, surface-polishing machine tools, etc., to achieve the effects of reducing the chance of wafer scratches, simple device structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

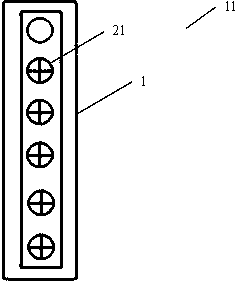

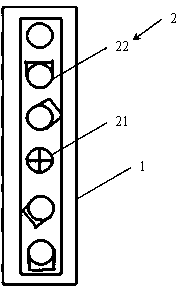

[0024] A kind of chemical mechanical polishing equipment used in semiconductor production, including a plurality of polishing tables 10, a plurality of polishing heads are arranged above the polishing table 10, a top cover is arranged above the polishing heads, and a wafer is also arranged at the adjacent position of the polishing table 10 Carrying mechanism 12, during wafer polishing production, a polishing pad is set on each polishing table 10, and abrasive liquid is added on the polishing pad, and the polishing head holds the wafer to be polished facing down and presses it on the polishing table 10 for polishing. Polishing is carried out on the pad, and each polishing head is movable.

[0025] See attached Figure 4 As shown, a cleaning device for chemical mechanical polishing equipment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com