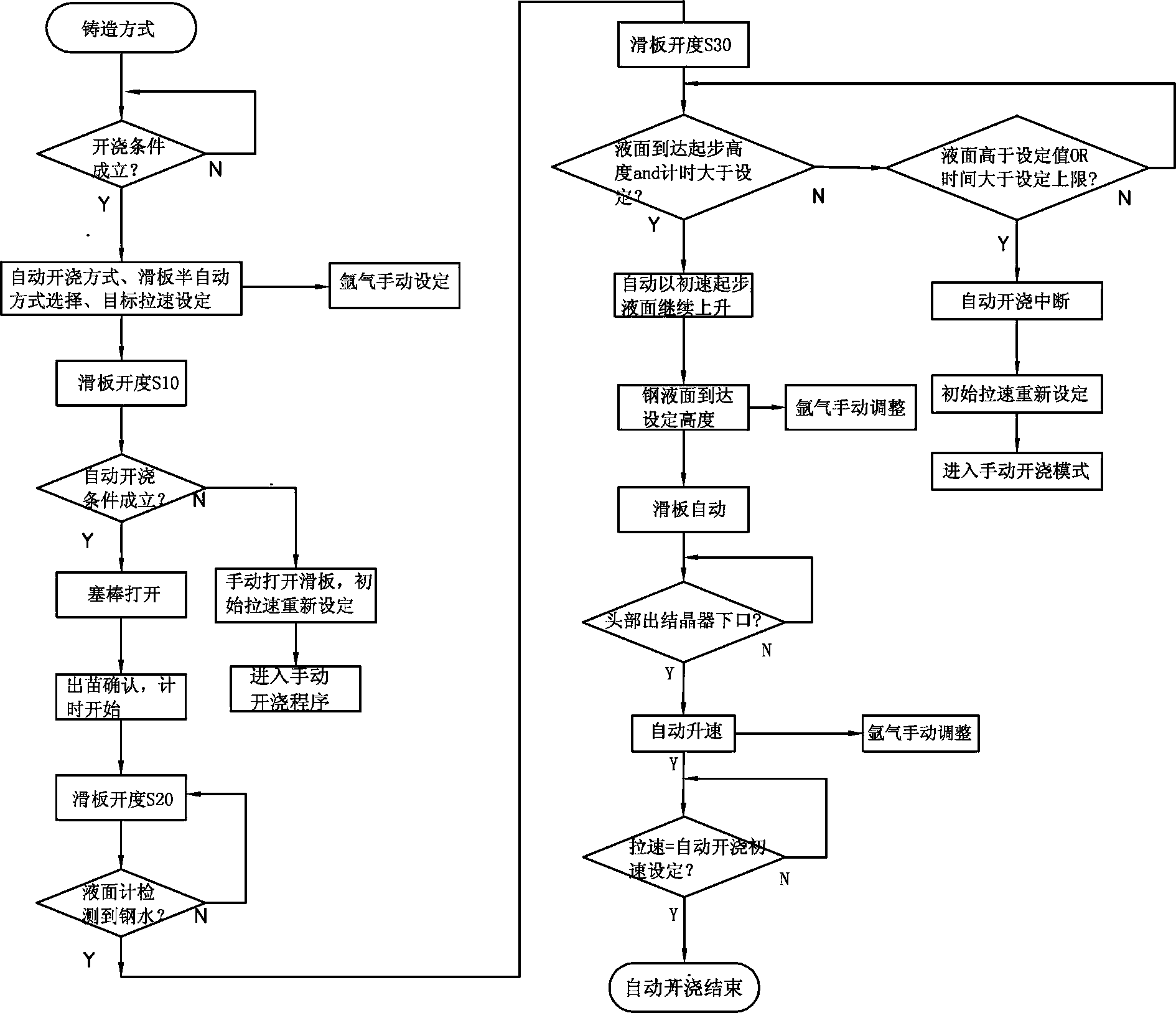

Control method for automatic casting of plug-in continuous casting machine

A technology of automatic pouring and control method, which is applied in the field of automatic pouring control of plug-in continuous casting machines, to achieve the effect of large opening, not easy to cold steel, and to prevent quality defects and abnormal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

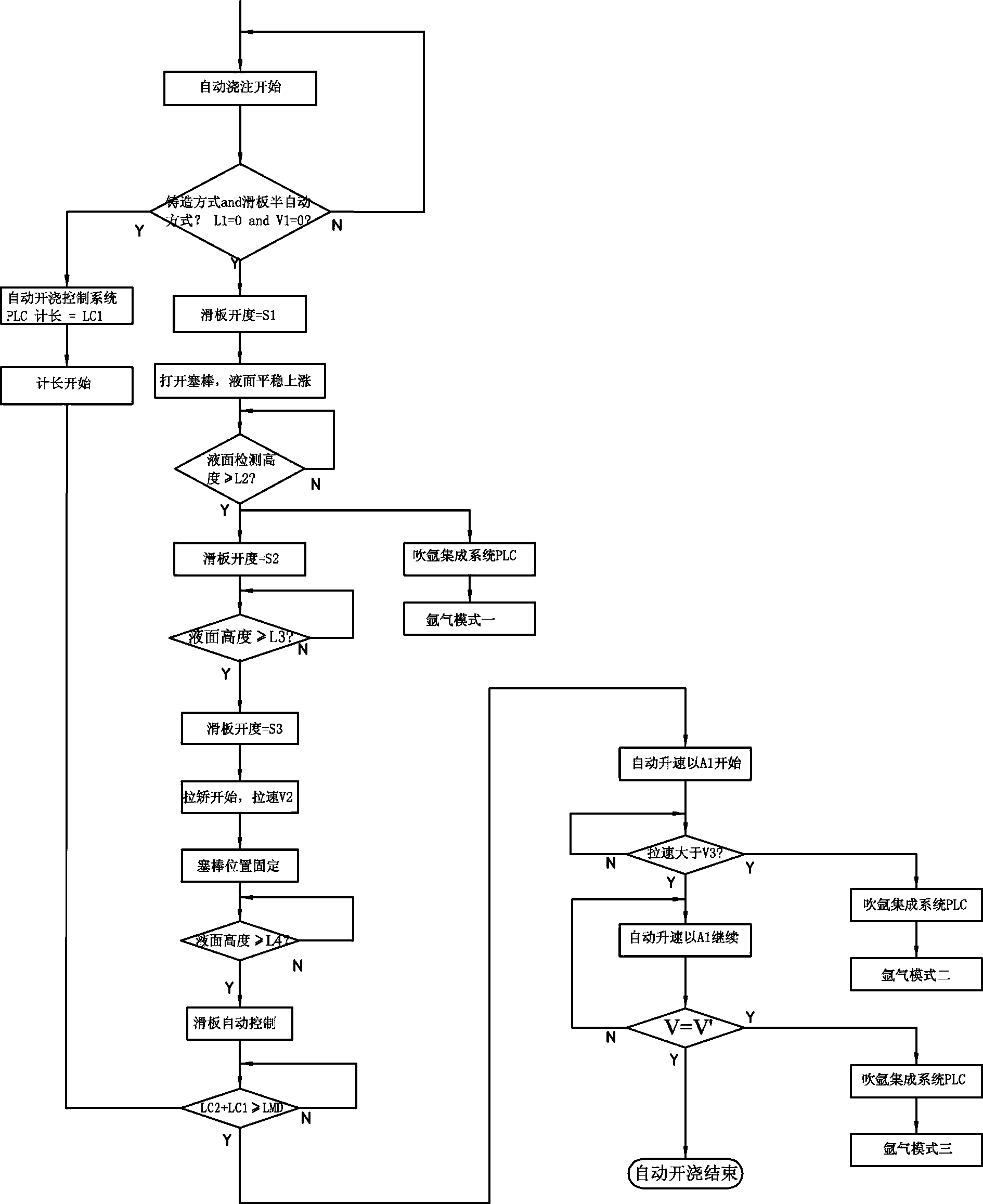

Embodiment 1

[0071] Confirm that the casting machine is in the casting mode, the actual casting speed of the casting machine is 0m / min, the mold liquid level detection display is 0, the sliding plate control mode is selected as semi-automatic mode, and the sliding plate opening is 100%.

[0072] When the above four conditions are satisfied, the automatic pouring starts, the length of the automatic pouring control system is 0.6m, the target casting speed of the strand is set at 0.8m / min, and the initial velocity of the strand is V1=0.35m / min.

[0073] When the molten steel in the tundish reaches a certain height, the stopper is manually judged and opened, and the pouring begins. The operator controls the steady rise of the molten steel in the crystallizer according to the steel flow situation and the countdown time of the central control.

[0074] When the crystallizer liquid level detection height = 10mm, the automatic pouring control system assigns the sliding plate opening to 60%, and at ...

Embodiment 2

[0081] Confirm that the casting machine is in the casting mode, the actual casting speed of the casting machine is 0m / min, the mold liquid level detection display is 0, the sliding plate control mode is selected as semi-automatic mode, and the sliding plate opening is 80%.

[0082] When the above four conditions are met, the automatic pouring starts, the automatic pouring control system PLC measures 0.5m, the target casting speed of the strand is set to 1.2m / min, and the initial velocity of the strand is V1=0.4m / min.

[0083] When the molten steel in the tundish reaches a certain height, the stopper is manually judged and opened, and the pouring begins. The operator controls the steady rise of the molten steel in the crystallizer according to the steel flow situation and the countdown time of the central control.

[0084] When the crystallizer liquid level detection height = 20mm, the automatic pouring control system assigns the opening of the sliding plate to 50%, and at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com