Split type board floating clamp on numerical control press

A CNC punching, split-type technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of affecting sheet metal processing accuracy, low detection accuracy, and short life of photoelectric detection heads, to improve the use of Longevity and reliability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

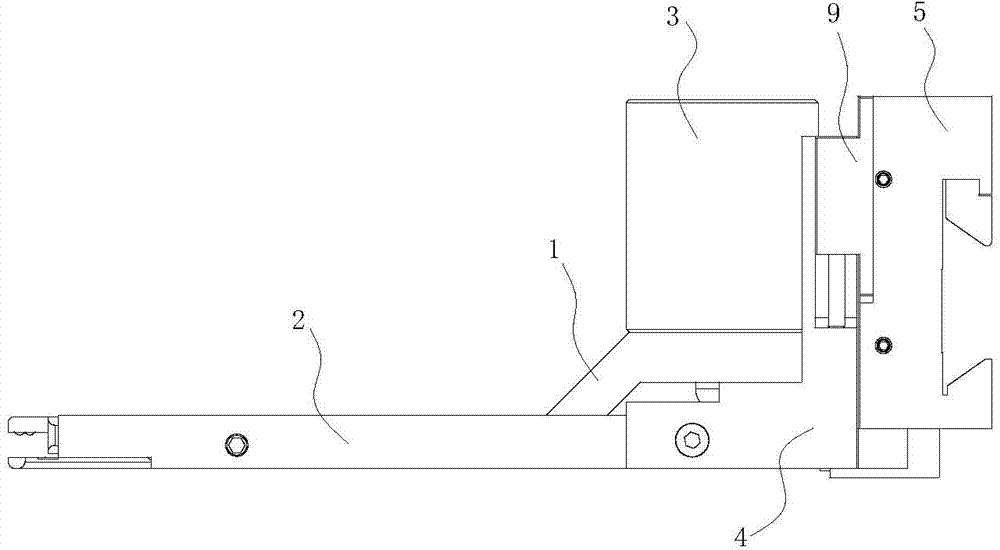

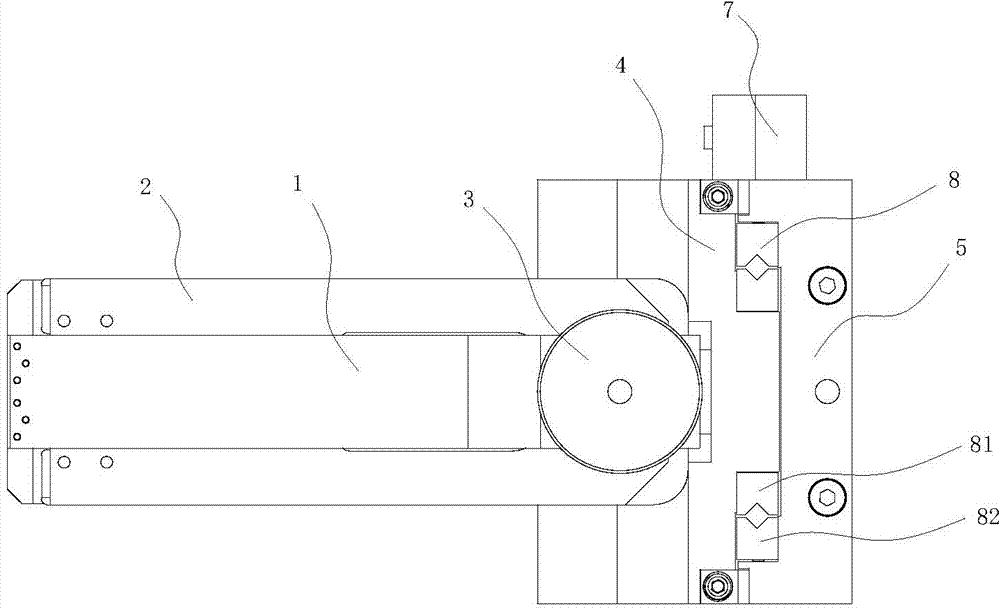

[0040] The present invention as Figure 1-9 As shown, it includes an upper pliers body 1, a lower pliers body 2 and a cylinder 3, the upper pliers body 1 and the lower pliers body 2 are hingedly connected, and the cylinder 3 is connected above the pliers tail end of the upper pliers body 1;

[0041] In the application, the standard cylinder with a longer stroke is used for the cylinder to avoid the problem of short stroke of the self-made cylinder. Due to the principle of force balance, under the premise of a certain air pressure, by moving the fulcrum of the upper and lower jaws forward, the clamping force on the jaws will be reduced. Increased holding power.

[0042] It also includes a base 4, a dovetail seat 5, a cylinder pad 6, a laser positioner 7, a pair of cross roller guide rails 8 and a pair of elastic guide mechanisms 9;

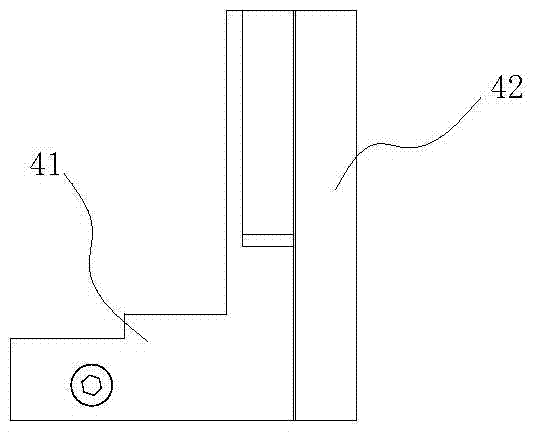

[0043] Such as Figure 3-6 As shown, the base 4 is L-shaped, including a connecting portion 41 at the front end and a guide portion 42 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com