Wiping cloth with multilayered structure and processing method for wiping cloth

A processing method and wiping cloth technology, which is applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of solvent secondary pollution, thin thickness of wiping cloth, and less liquid retention, and achieve high controllability and simple processing method , soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

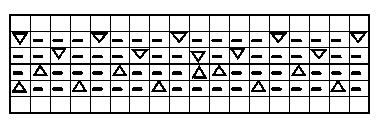

[0044] On the double-sided circular knitting machine of E24, 84dtex-288f-PET (1 piece) false twisted stretched yarn obtained by direct spinning with a monofilament fineness of 0.29dtex is used as the upper and lower layer yarns, and the monofilament fineness obtained by direct spinning 110dtex-144f-PET (2 pieces) of 0.76 dtex is used as the middle layer yarn, and the weaving structure is shown in the attachment figure 1 , the middle layer needle cylinder and dial, while the upper knitting only needles out of the needle cylinder, the lower layer knitting only needles out of the dial, the knitting length ratio of the middle layer to the upper and lower layers is set to 1.7 to 1.8, ultra-fine PET and ordinary PET Weaving under the feed ratio of 64 / 36, then scouring and degreasing under the condition of 95 degrees * 30 minutes, loosening and washing with hot water, to obtain the wiping cloth of the present invention.

[0045] After testing, the water absorption rate of the obtaine...

Embodiment 2

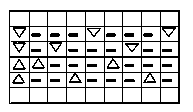

[0047]On the double-sided circular knitting machine of E18, 84dtex-288f-PET (1 piece) false twisted stretched yarn obtained by direct spinning with a monofilament fineness of 0.29dtex is used as the upper and lower layer yarns, and the monofilament fineness obtained by direct spinning 167dtex-144f-PET (2 strands) of 1.16dtex is used as the middle layer yarn, and the weaving structure is shown in the attachment figure 2 , the needle cylinder and the dial of the middle layer come out, while the upper layer knits only the needles come out of the needle cylinder, and the lower layer knits only the needles come out of the dial. Weaving under the feed ratio of 50 / 50, then scouring and degreasing under the condition of 120 degrees * 20 minutes, hot water loosening and washing, to obtain the wiping cloth of the present invention.

[0048] After testing, the water absorption rate of the obtained wiping cloth has reached more than 285%, and the thickness is 0.8mm. The ordinary polyeste...

Embodiment 3

[0050] On the E24 double-sided circular knitting machine, 84dtex-288f-PET (1 piece) false twisted stretched yarn obtained by direct spinning with a monofilament fineness of 0.29dtex is used as the upper layer yarn, and the monofilament fineness obtained by direct spinning is 0.76 dtex 110dtex-144f-PET (1 piece) false-twisted stretched yarn, and 167dtex-144f-PET false-twisted stretched yarn with a monofilament size of 1.16dtex obtained by direct spinning as the middle layer yarn, the organization is shown in the appendix figure 1 , the middle layer needle cylinder and dial, while the upper knitting only needles out of the needle cylinder, the lower layer knitting only needles out of the dial, the knitting length ratio of the middle layer to the upper and lower layers is set to 1.6 to 1.7, ultra-fine PET and ordinary PET Weaving under the feed ratio of 60 / 40, then scouring and degreasing under the condition of 98°C for 30 minutes, loosening and washing with hot water, to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com