Multi-color solder mask layer

A technology of solder mask and color, applied in the direction of coating non-metallic protective layer, secondary treatment of printed circuit, printed circuit components, etc., can solve the problems of long processing time, single printing color, poor bonding force, etc., to achieve cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

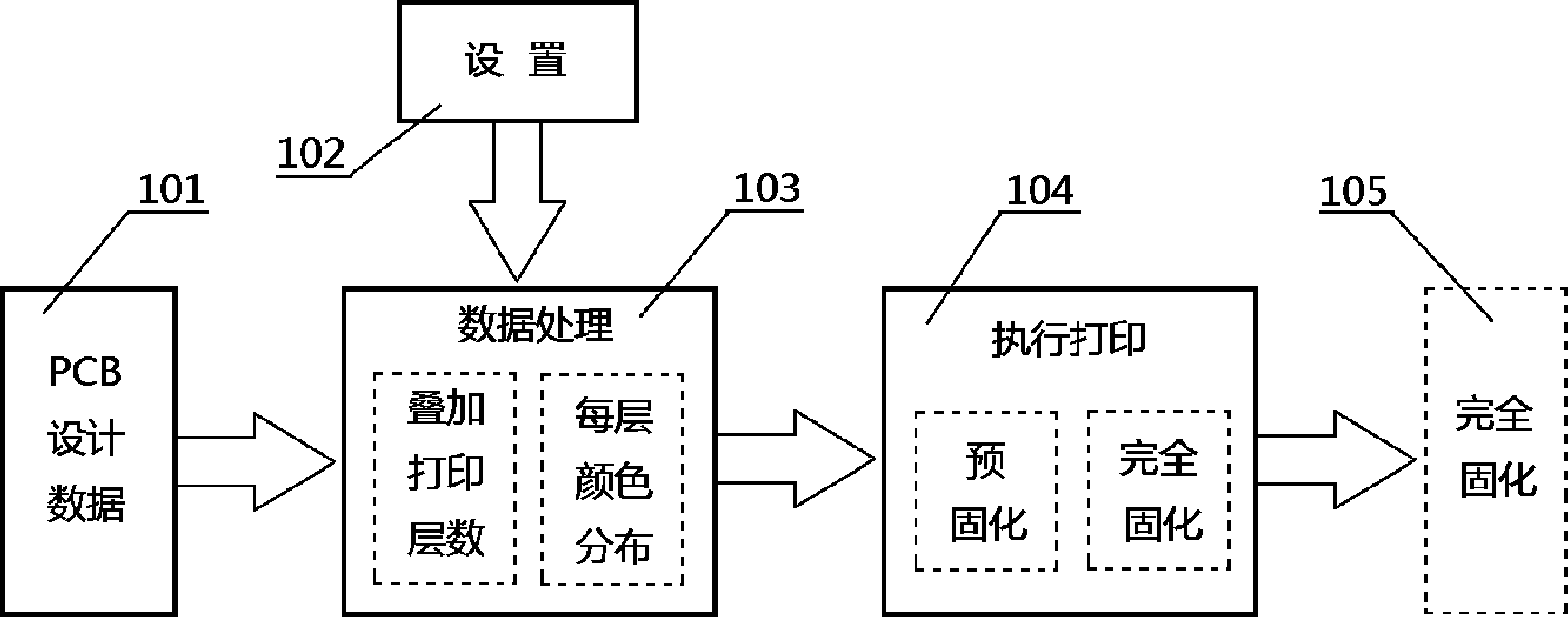

[0030] See attached figure 1 method shown. First, block 103 performs data processing according to the PCB design data represented by block 101 and the settings represented by block 102, and outputs the result. Block 103 processes the data to obtain the data required for printing the solder resist layer, such as: the number of overprinted layers, the color distribution of each layer, and the like.

[0031] Then, block 104 executes the printing task according to the output result of block 103, and prints out the required solder resist layer.

[0032] Because the ink used to print the solder mask is different, different methods are required for curing. UV solder mask ink is selected, which needs to be cured by UV light, and can be pre-cured first and then fully cured, or directly fully cured.

[0033] As a commonly used curing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com