Inflation pressure-controllable packaging system for manufacturing organic electroluminescent devices

A technology of inflation pressure and packaging system, which is applied in the direction of electrical solid devices, semiconductor/solid device manufacturing, electrical components, etc., can solve the problems of troublesome operation, high maintenance cost, expensive glove box equipment, etc., and achieve easy replacement, cost saving, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

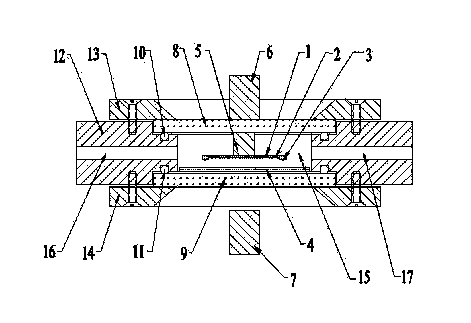

[0030] see figure 1 , the controllable inflation pressure packaging system for making organic electroluminescent devices includes gas cylinders (22), gas purifiers (21), intake valves (20), vacuum gauges (19), exhaust valves (23), exhaust The air system (24), the sample sealing device (25) are connected by the air pipe (18) and the ultraviolet light source (26). The sample sealing device is composed of an air inlet pipe (16), an exhaust pipe ( 17) Vacuum base (12), upper sealing ring (10), lower sealing ring (11), upper pressing plate (13), lower pressing plate (14) press the upper transparent cover (8) and the lower transparent cover ( 9) A closed vacuum chamber (15) is formed, a substrate (4) with an organic light-emitting layer is placed in the lower part of the vacuum chamber (15), and a movable magnet (5) with an adhesive underneath is placed in the upper part It is bonded with a glass sealing back cover (1) with a groove, a getter (2) is placed in its groove, and a thin...

Embodiment 2

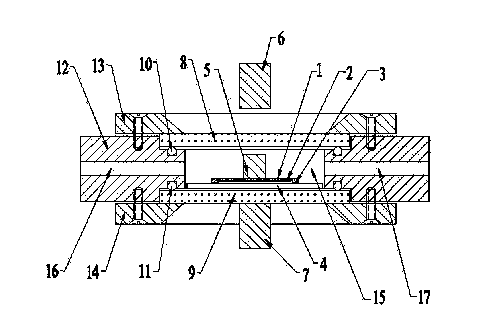

[0034] see Figure 4, the production of organic electroluminescent devices can control the inflation pressure packaging system including gas cylinders (22), gas purifiers (21), intake valves (20), vacuum gauges (19), exhaust valves (23), exhaust The system (24) and the sample sealing device (25) are connected by a gas pipe (18). The sample sealing device is composed of a vacuum base (12), an upper sealing ring (10), a lower sealing ring (11), an upper pressing plate (13) 1. The lower pressing plate (14) presses the upper transparent cover (8) and the lower transparent cover (9) to form a closed vacuum chamber (15), and an organic light-emitting device is placed in the lower part of the vacuum chamber (15). Layered substrate (4), the upper part has a movable magnet (5) with adhesive below it, and it is bonded by adhesive to place a glass sealed rear cover (1) with a groove, and a suction magnet is placed in the groove agent (2), a thin layer of sealant (3) is placed on the...

Embodiment 3

[0038] This embodiment is basically the same as Embodiment 1, and its special feature is that a thin layer of sealant (3) is placed on the peripheral bead of the glass-sealed back cover (1) using heat-cured resin, Therefore, the used light source (26) is an infrared light source, which generates infrared heat to cure the resin, and glues the glass rear cover (1) and the periphery of the organic light-emitting substrate (4) together to complete the entire packaging process.

[0039] In this embodiment, the gas in the gas cylinder (22) is a mixed gas of high-purity nitrogen and a small amount of ammonia. The gas purifier (21) has the function of removing moisture and oxygen, the air extraction system (24) is a mechanical vacuum pump, the vacuum base (12) and the upper and lower pressure plates (13) and (14) in the sample sealing device (25) It is made of aluminum, and the upper and lower transparent cover plates (8) and (9) are glass sheets.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com