High-elasticity anti-twist wind energy cable with nominal voltage of six to thirty-five kilowatts and manufacturing method

A technology with rated voltage and high elasticity, applied in the manufacture of cables/conductors, flexible cables, power cables with shielding layers/conducting layers, etc. Long life and effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

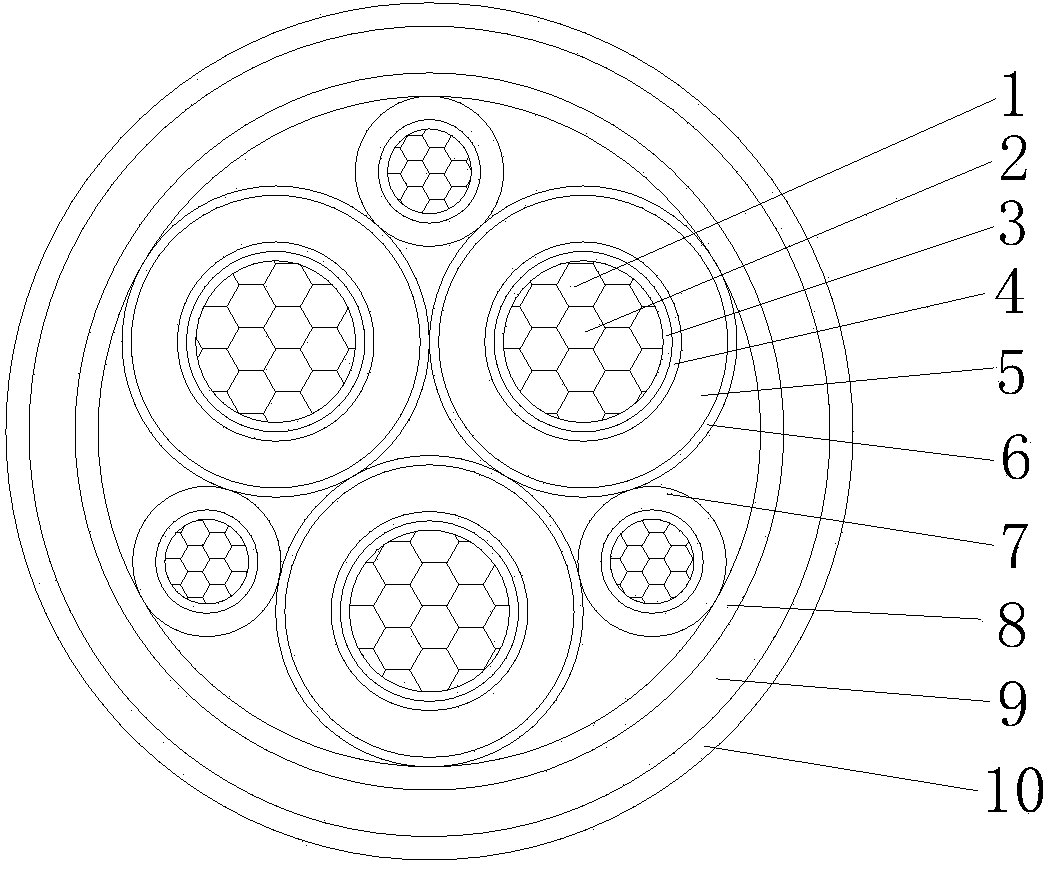

[0056] Embodiment: The rated voltage of the present invention is 6-35kV high elastic and twist-resistant wind energy cable, which consists of three power insulated wire cores and three grounded insulated wire cores twisted to form a cable core. The ribbon 8 is extruded with a thermoplastic elastomer outer sheath 9, and the outermost layer of the cable is a braided layer 10 of stainless steel wire, polyamide or polyester synthetic fiber yarn;

[0057] Each power insulated wire core is made of tinned oxygen-free copper wire 1 and stainless steel wire 2 twisted to form a conductor, and the conductor is overlapped and wrapped with a single-layer semi-conductive cotton tape wrapping layer 3, and the outer wrapping layer 3 is co-extruded with three layers There is a conductor shielding layer 4, an EPDM insulating layer 5 and an insulating shielding layer 6 to form a power insulating core;

[0058] Each grounding insulated wire core is made of tinned oxygen-free copper wire and stain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com