LED (light-emitting diode) backlight driving circuit, backlight module and liquid crystal display device

A technology of backlight drive circuit and LED light bar, which is applied to static indicators, instruments, etc., can solve problems such as rising costs, achieve high conversion efficiency, reduce energy consumption, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

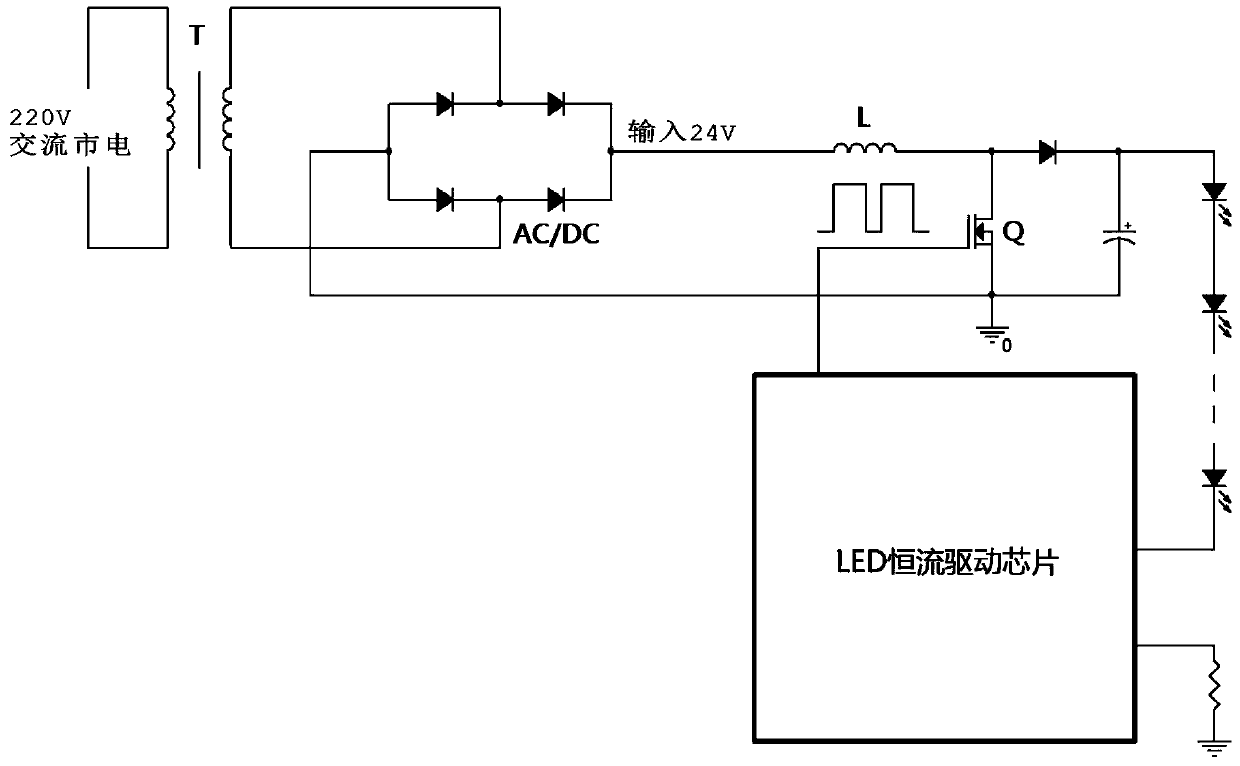

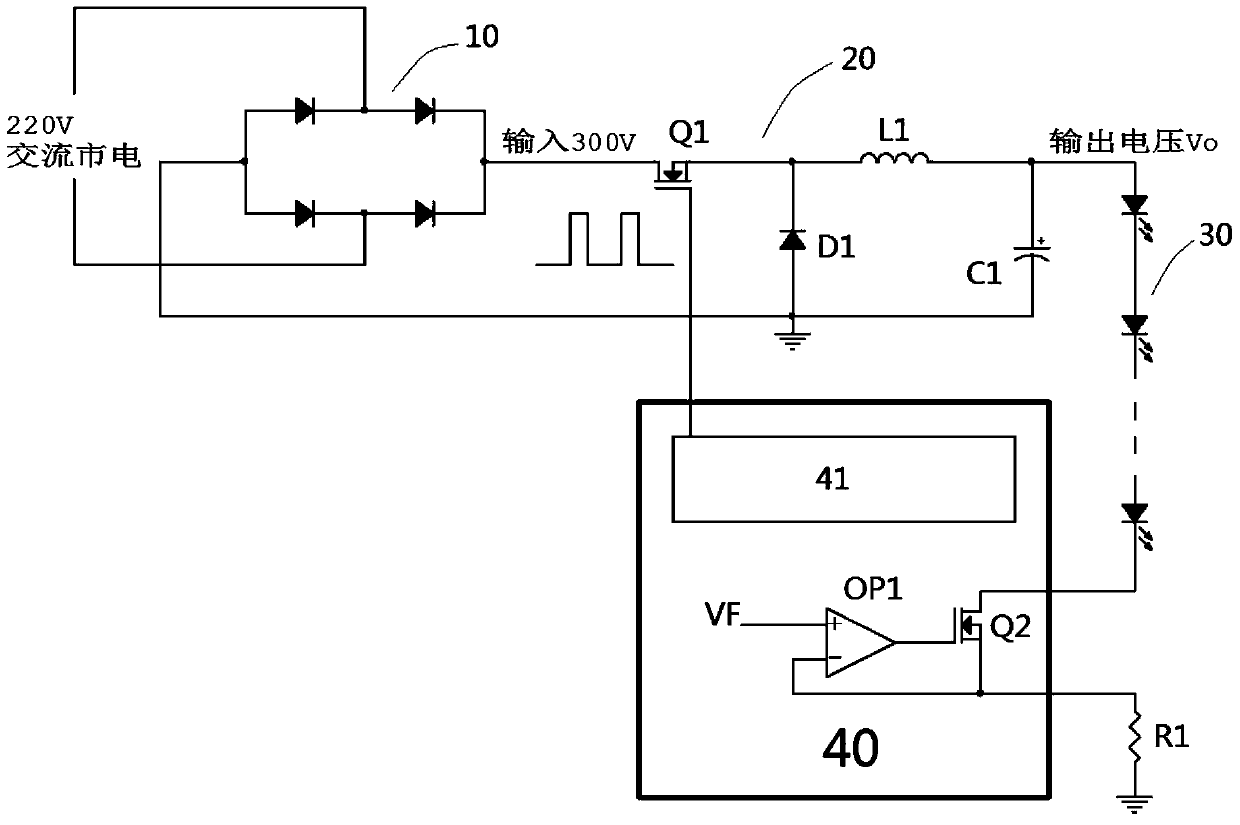

[0025] The invention discloses a liquid crystal display device. The liquid crystal display device includes a liquid crystal panel and a backlight module providing light source for the liquid crystal panel. The backlight module includes an LED backlight driving circuit. Such as figure 2 As shown, the LED backlight drive circuit includes a rectifier module 10 directly connected to the mains, a step-down module 20 coupled to the rectifier module 10 and controlled by PWM, and an LED light bar 30 directly coupled to the step-down module 20 .

[0026] After research, according to the calculation formula of the boost circuit: Vo=Vin / (1-D), when the voltage Vo required by the LED light bar is high, the duty cycle D of the MOS tube driving signal will also increase, which means that in The conduction time of the voltage-regulating controllable switch in one cycle increases, and the current flowing in the MOS tube is relatively large, which will cause power loss and heat generation, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com