Micro cantilever beam array biochemical sensing device based on micro-mirror scanning and method

An array sensing and micro-beam technology, applied in the field of biochemical sensing, can solve the problems affecting the detection quality of spot displacement, the adjacent distance cannot be adjusted, and the detection sensitivity is not high, and achieve convenient and fast positioning detection, low cost, and detection optical path structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1. Measurement of temperature changes by the microbeam array sensing method based on micromirror scanning

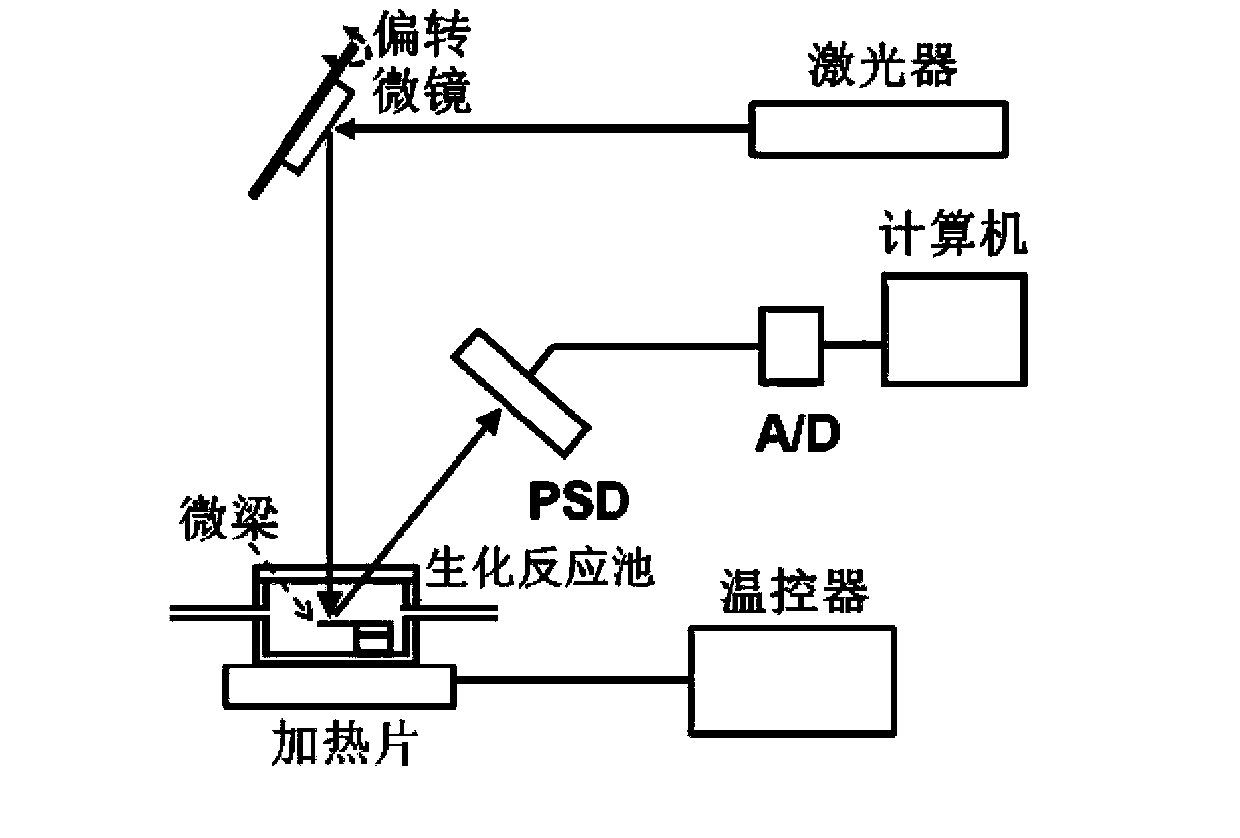

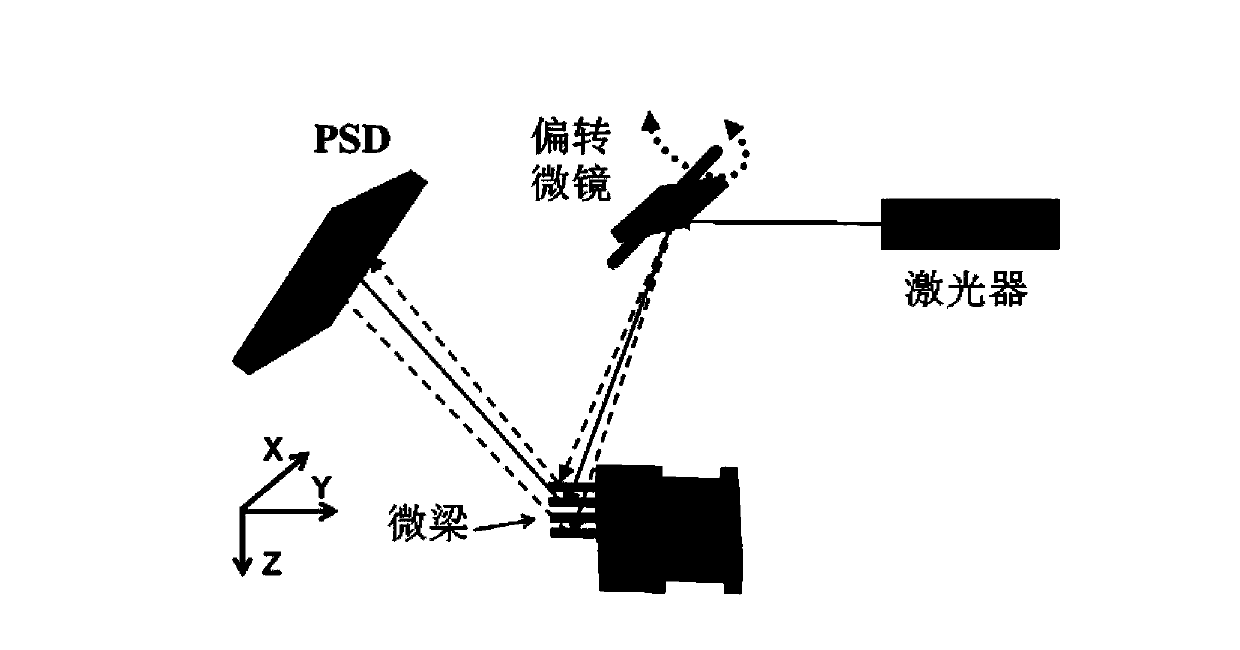

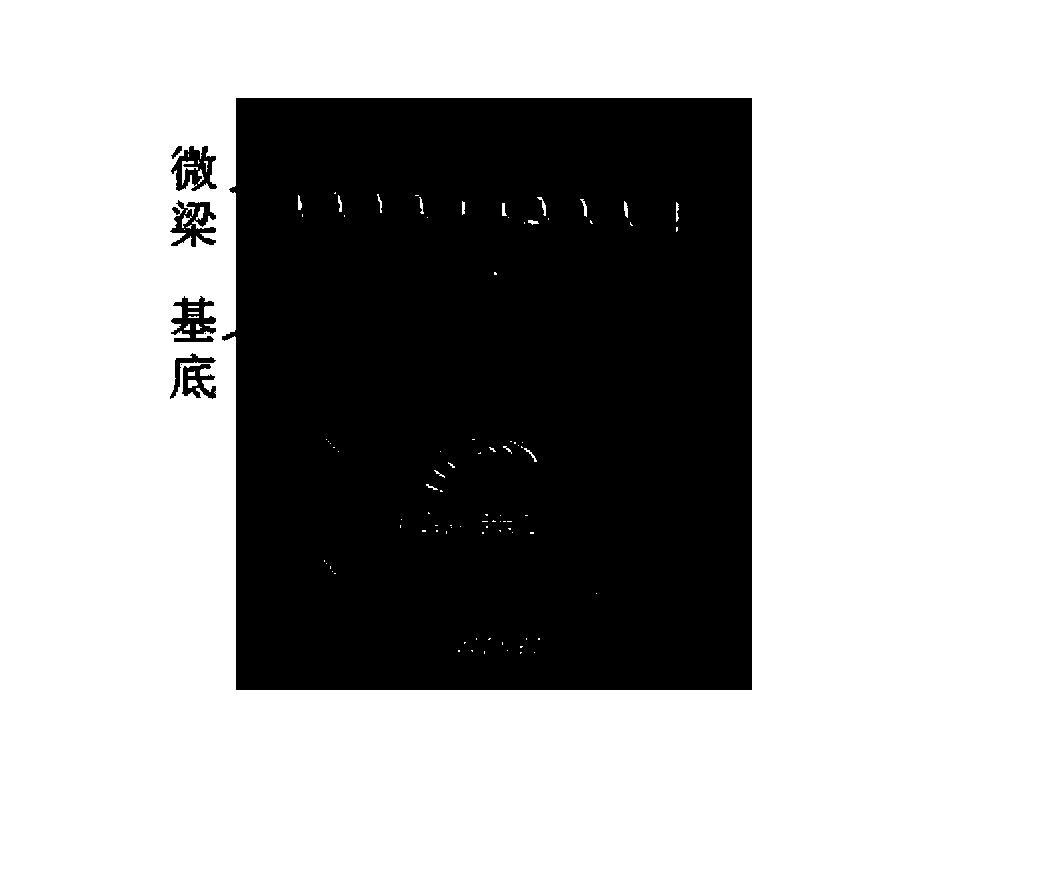

[0086] 1. A commercial microbeam array (German micromotive company, such as image 3 As shown, the microbeams are 500 μm long, 90 μm wide, and 1 μm thick, and the surface is coated with a 0.02 μm thick gold layer, and the center-to-center distance between two microbeams is 250 μm) fixed to the system (including lasers, deflection micromirrors, biochemical reaction pools) , thermostat, PSD, A / D converter, computer, such as figure 1 Shown) in the biochemical reaction pool.

[0087] 2. The converging laser beam emitted by the semiconductor laser is deflected by the micromirror and then periodically scans two fixed points with a distance of 250 μm on the substrate of the microbeam array for 9 hours. The scanning displacement curve is as follows Figure 4 As shown: In the X direction and Y direction, the two scanning positions are kept parallel and consistent...

Embodiment 2

[0089] Example 2. Detection of Clenbuterol by Microbeam Array Biochemical Sensing Method Based on Microscope Scanning

[0090] 1. Experimental Setup and Reagents

[0091] The specific structure of the detection system is as follows: figure 1 As shown in , it mainly includes laser (parameters: diameter 8mm, length 20mm, wavelength of laser emission is 650nm, laser focus spot diameter is 200μm), deflection micromirror (parameters: driving voltage 40V~50V, driving frequency 3KHz, scanning angle range 10°), biochemical reaction pool (volume 0.5mL, fully sealed, composed of a 1mm inner diameter sample inlet, an inner diameter 1mm sample outlet, a glass sheet, and a microbeam fixing table, Figure 9 ), temperature controller (temperature control accuracy 0.01℃, temperature control range 0℃~100℃), PSD (displacement resolution 1μm, target surface size 12mm×12mm), A / D converter (12 bits), computer.

[0092] Clenbuterol antibody, clenbuterol standard sample CLEN, chloramphenicol stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com