Method for preparing simple substance iron by virtue of pyrolytic gas

A technology of pyrolysis of gas and iron, which is applied in the field of metallurgy and can solve problems such as shortage of natural gas resources, heavy pollution, and poor efficiency of direct reduction of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

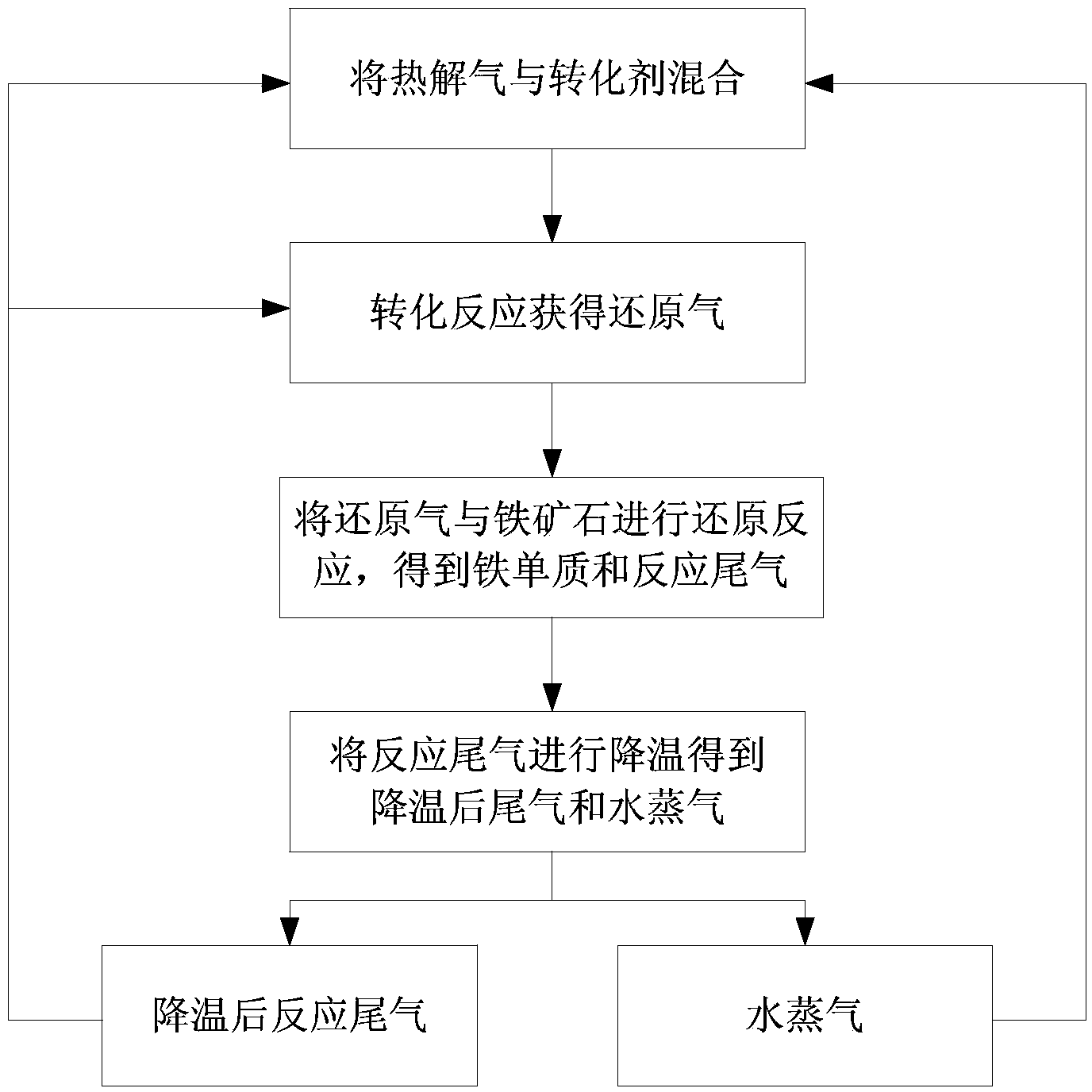

Method used

Image

Examples

Embodiment

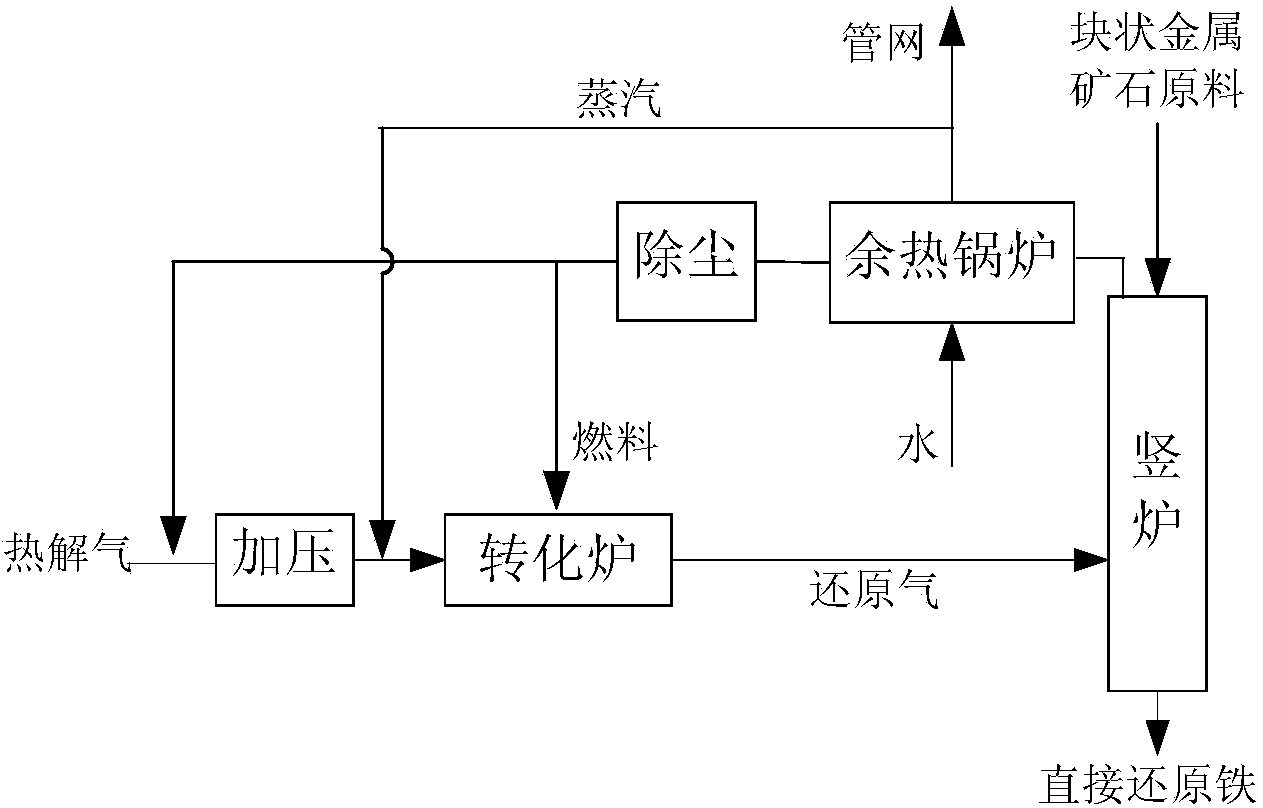

[0041] refer to figure 2 , Iron ore is smelted by using lignite pyrolysis gas in a certain place, in which the lignite pyrolysis gas in a certain place mainly contains 24% volume H 2 , 11% volume CO, 22% volume CO 2 , 27% volume CH 4 , 9% volume C 2+ , 6% volume H 2 O and nitrogen, etc. The lignite pyrolysis gas is mixed with 60% cooled and dust-removed reaction tail gas, pressurized to 3bar, mixed with steam, and passed into the reformer, where the conversion reaction occurs, wherein the volume ratio of steam to lignite pyrolysis gas is 0.1, and the temperature of the conversion reaction is The temperature is 450-900°C, and the pressure is 4bar. The reducing gas thus prepared contains H 2 The total volume of CO and CO is at least 85% by volume, and the reducing gas temperature is 900°C. The converted reducing gas is fed into the shaft furnace to reduce the bulk metal ore raw material, and the product direct reduced iron is obtained. The reaction tail gas discharged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com