A kind of compound probiotics and preparation method thereof

A compound microecology and preparation technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of insignificant effect of compound microecological preparations, poor strain activity, and increased production costs. Improved average daily gain and immune performance, improved immunity, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Culture medium preparation

[0032] YPD medium: including 10g / L yeast powder, 20g / L peptone B and 20g / L D-anhydrous glucose, sterilized at 115°C for 15 minutes;

[0033] MRS medium: including 10.0g / L peptone, 8.0g / L beef powder, 4.0g / L yeast powder, 20.0g / L glucose, 2.0g / L dipotassium hydrogen phosphate, 2.0g / L Diamine hydrogen citrate, 5.0g / L sodium acetate, 0.2g / L magnesium sulfate, 0.04g / L manganese sulfate and 1.0g / L Tween~80, adjust the pH value to 5.7±0.2 at 25°C , sterilized at 118°C for 15 minutes;

[0034] LB medium: including 10.0g / L tryptone, 5.0g / L yeast extract powder and 10.0g / L sodium chloride, adjust the pH value to 7.0±0.1 at 25°C, and sterilize at 121°C for 15 minutes.

[0035] Add 2g / L agar to the above culture medium to prepare a solid culture medium.

[0036] 2. Preparation method

[0037] (1) Cultivation of Lactobacillus casei

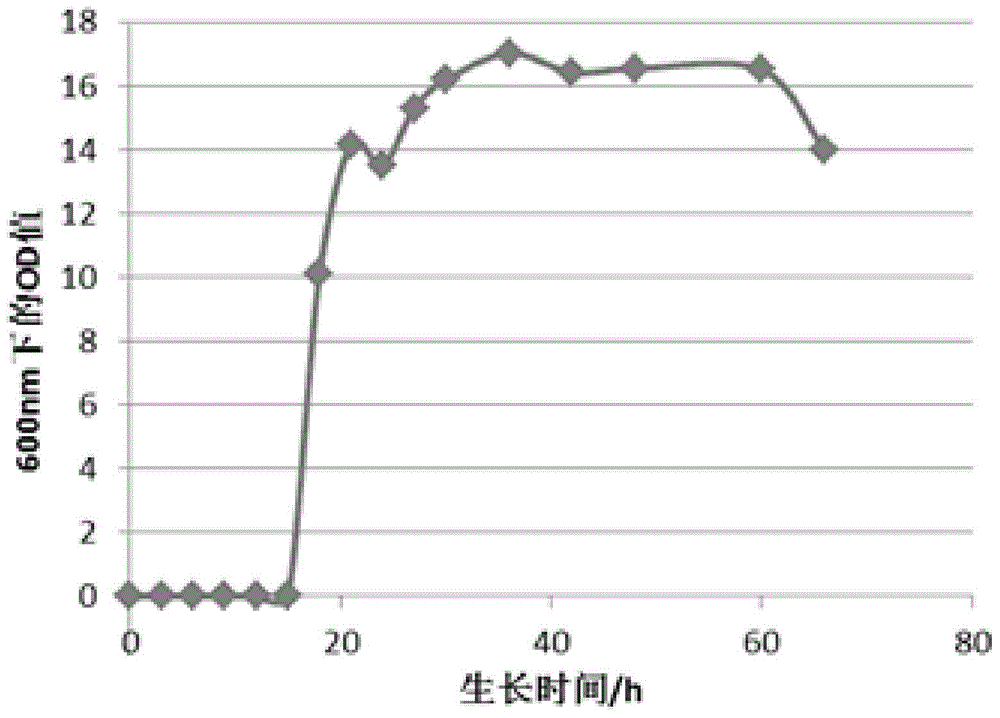

[0038] Under sterile conditions, take the freeze-dried strain of Lactobacillus casei, spread it on the MRS solid me...

Embodiment 2

[0048] In this embodiment, the preparation of the culture medium is the same as in Example 1, and the preparation method includes the following steps:

[0049] (1) Cultivation of Lactobacillus casei

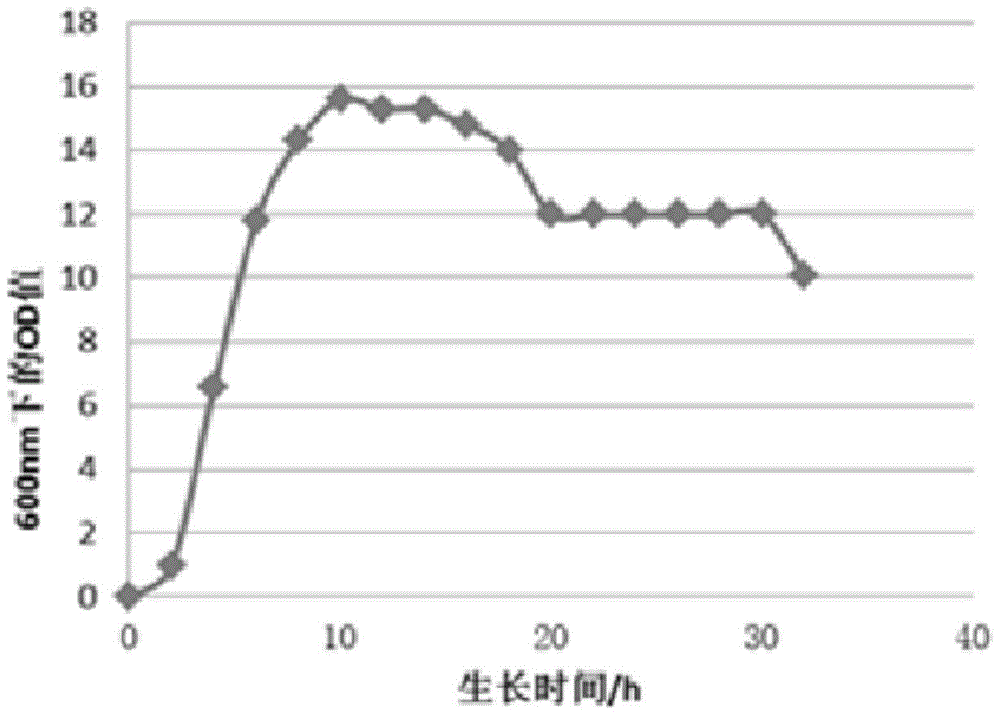

[0050] Under sterile conditions, take the freeze-dried strain of Lactobacillus casei, spread it on the MRS solid medium, and culture it statically at 37°C for 20 hours, pick a single colony, and further streak and purify it on the MRS solid medium, 37 After culturing at ℃ for 20 hours, pick a single colony, inoculate it into 100 mL of MRS liquid medium, and culture it statically for 24 hours under anaerobic conditions. At this time, Lactobacillus casei enters the late stage of exponential growth or late stationary phase. Inoculate into MRS culture medium, anaerobic static culture at 37°C for 24 hours to obtain Lactobacillus casei culture fluid;

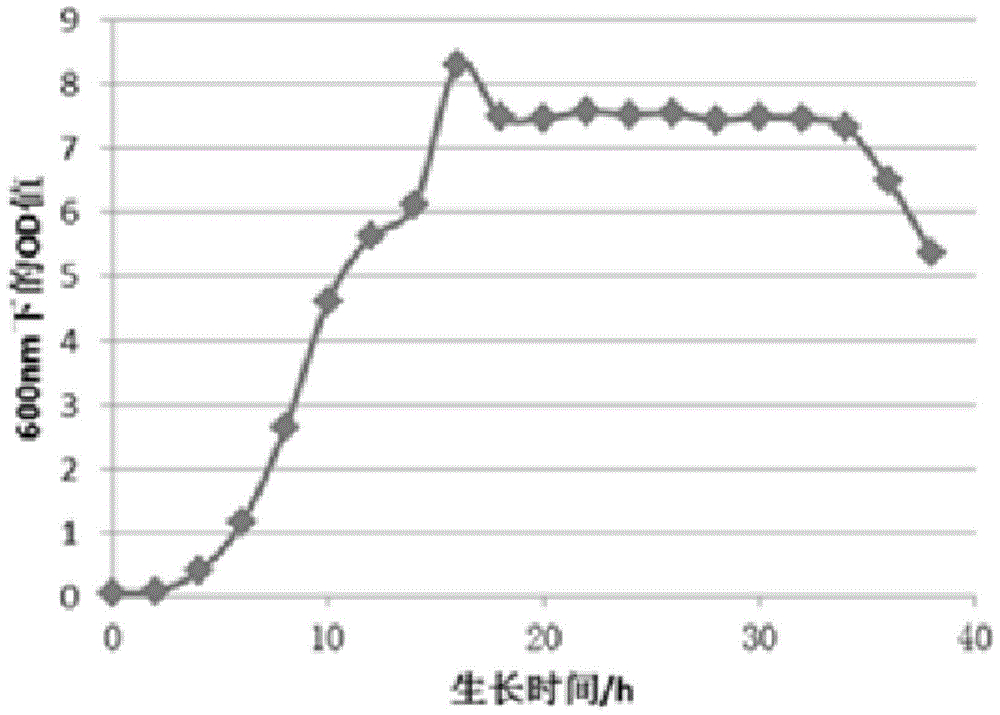

[0051] (2) Cultivation of Bacillus

[0052] Under sterile conditions, take 0.5g of chicken cecum content, add 4.5mL of sterile saline...

Embodiment 3

[0057] In this example, the bacterial concentration ratio of Bacillus cereus and Bacillus subtilis in step (3) is 1:3; in the mixed culture solution in step (4), Bacillus cereus, Bacillus subtilis and cheese milk The bacterial concentration ratio of bacilli is 1:3:2.5, and the rest of the steps and medium preparation are the same as in Example 2.

[0058] The compound probiotics prepared in Examples 1 to 3 were fed to 1-day-old broiler chicks respectively, and the chicks were divided into four groups, 15 in each group, and the average daily gain was measured within 1 to 42 days, and the broiler chicks were measured in 1-42 days. For the immune organ index at 42 days, in the blank control group, the probiotics were replaced with water, and the positive control was a composite probiotic prepared by lactic acid bacteria, bacillus, yeast zinc, and yeast selenium. The measurement results are shown in Table 1 below:

[0059] Table 1: Analysis of the influence of compound probiotics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com