A kind of preparation method of methanol gasoline composite additive

A compound additive, methanol gasoline technology, used in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of easy phase separation, excessive swelling of materials, large swelling force, etc. Prevent gum or precipitation, wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

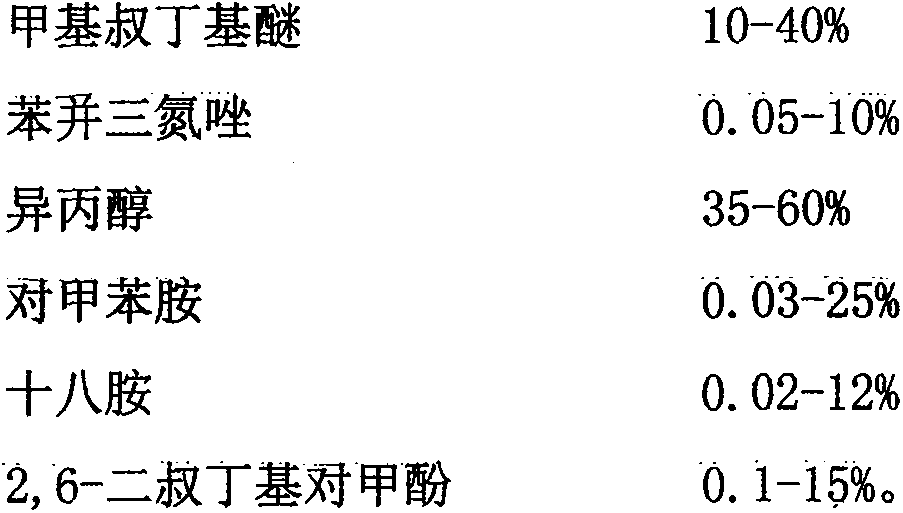

Method used

Image

Examples

Embodiment 1

[0019] The composition and mass percentage of the methanol-gasoline composite additive are: 25% of methyl tert-butyl ether, 6% of benzotriazole, 55% of isopropanol, 3.5% of p-toluidine, 0.5% of octadecylamine and 2 , 6-di-tert-butyl-p-cresol 10%,

[0020] The compounding process implementation of this methanol-gasoline composite additive:

[0021] ① First inject methyl tert-butyl ether and isopropanol into the mixing tank according to the ratio, reaching a point slightly lower than 3 / 5 of the volume of the mixing tank, and circulate and mix for about 10 minutes.

[0022] ②Add a certain amount of benzotriazole, p-toluidine, octadecylamine and 2,6-di-tert-butyl-p-cresol into the mixing tank in turn.

[0023] ③Start the mixing tank again, and circulate and mix for about 30 minutes, so that the solids are completely dissolved and mixed evenly.

[0024] ④ After the mixed solution is transferred out, it is filtered, and the filtered filtrate is sealed and stored to obtain the meth...

Embodiment 2

[0026] The composition and mass percent of the methanol-gasoline compound additive are: 40% of methyl tert-butyl ether, 2% of benzotriazole, 35% of isopropanol, 15.5% of p-toluidine, 2.5% of octadecylamine and 2 , 6-di-tert-butyl-p-cresol 5%.

[0027] The compounding process implementation of this methanol-gasoline composite additive:

[0028] ① First inject methyl tert-butyl ether and isopropanol into the mixing tank according to the ratio, reaching a point slightly lower than 3 / 5 of the volume of the mixing tank, and circulate and mix for about 15 minutes.

[0029] ②Add a certain amount of benzotriazole, p-toluidine, octadecylamine and 2,6-di-tert-butyl-p-cresol into the mixing tank in turn.

[0030] ③Start the mixing tank again, and circulate and mix for about 40 minutes, so that the solids are completely dissolved and mixed evenly.

[0031] ④ After the mixed solution is transferred out, it is filtered, and the filtered filtrate is sealed and stored to obtain the methanol...

Embodiment 3

[0033] The composition and mass percentage of the methanol-gasoline compound additive are: 55% of methyl tert-butyl ether, 0.5% of benzotriazole, 15% of isopropanol, 18% of p-toluidine, 8.5% of octadecylamine and 2 , 6-di-tert-butyl-p-cresol 1%.

[0034] The compounding process implementation of this methanol-gasoline composite additive:

[0035] ① First inject methyl tert-butyl ether and isopropanol into the mixing tank according to the ratio, reaching a point slightly lower than 3 / 5 of the volume of the mixing tank, and circulate and mix for about 20 minutes.

[0036] ②Add a certain amount of benzotriazole, p-toluidine, octadecylamine and 2,6-di-tert-butyl-p-cresol into the mixing tank in sequence.

[0037] ③Start the mixing tank again, and circulate and mix for about 50 minutes, so that the solids are completely dissolved and mixed evenly.

[0038] ④ After the mixed solution is transferred out, it is filtered, and the filtered filtrate is sealed and stored to obtain the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com