Long-acting mixed fluorocarbon surfactant treating agent for improving condensate gas reservoir recovery efficiency and application of mixed fluorocarbon surfactant treating agent

A surface active agent and fluorocarbon surface technology, which is applied to the drilling composition, production fluid, earthwork drilling and production, etc., can solve the problems of low recovery rate and short validity period, and achieve enhanced recovery rate, long validity period, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

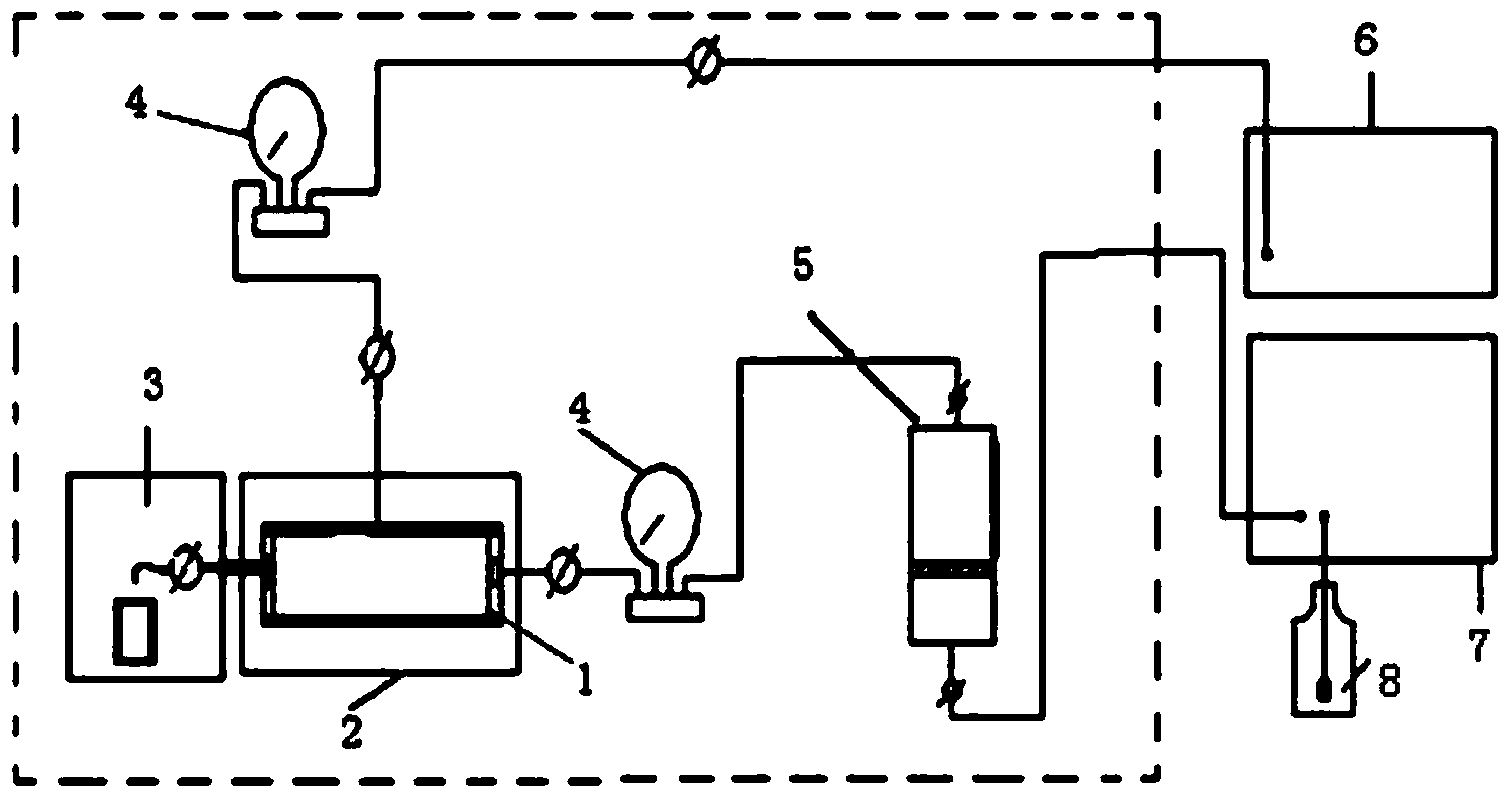

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: long-acting mixed fluorocarbon surfactant treatment agent, raw material components are as follows by mass percentage:

[0059] Nonionic Fluorocarbon Surfactant CF 3 (CF 2 ) 7 (CH 2 CH 2 O) 20 H0.1%, zwitterionic fluorocarbon surfactant DF-9210.1%, nonionic hydrocarbon surfactant OP-200.1%, ethanol 20%, and the rest is water.

[0060] Mix the above components evenly to obtain the treatment agent, and the solution of the treatment agent remains clear and transparent at 140°C.

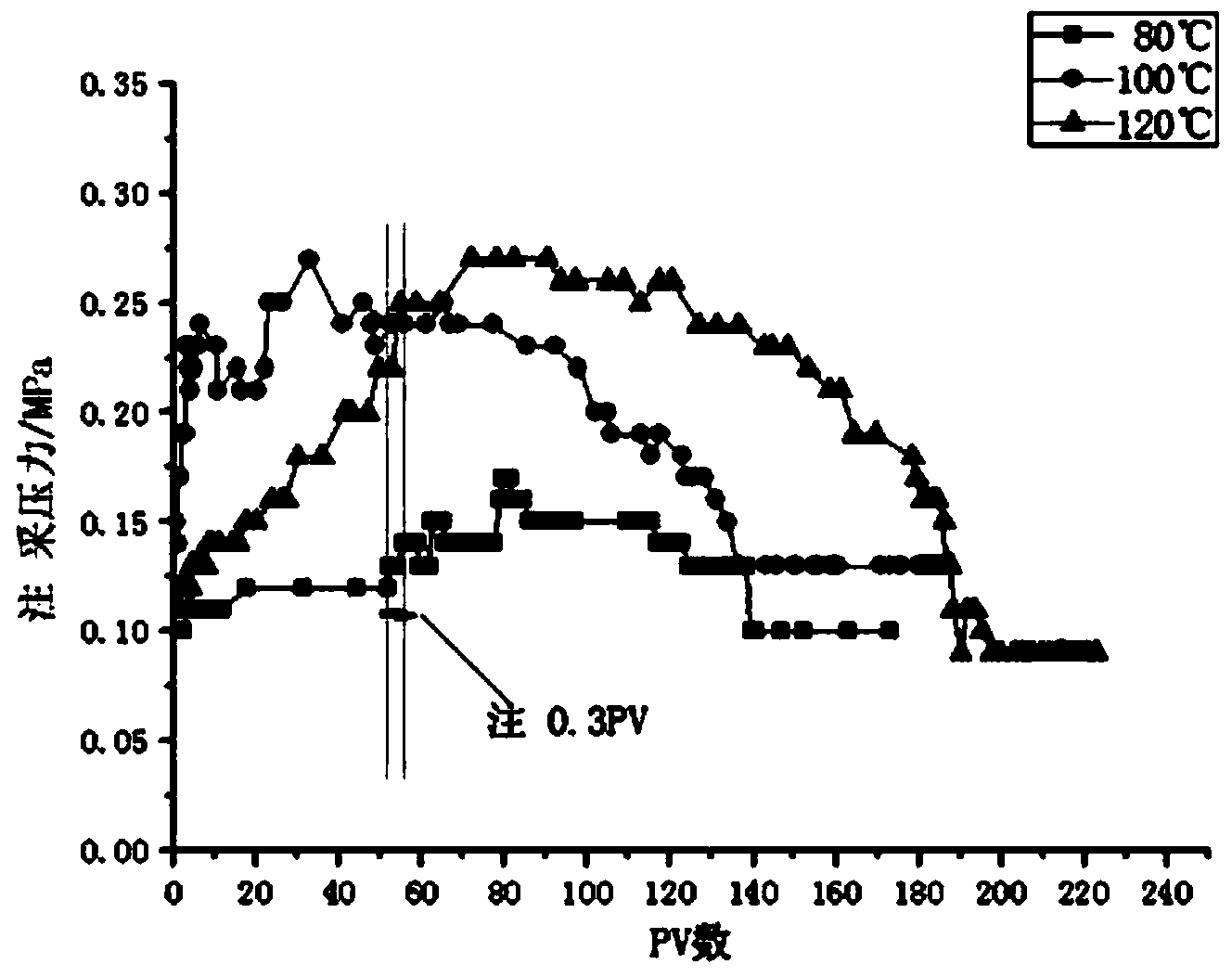

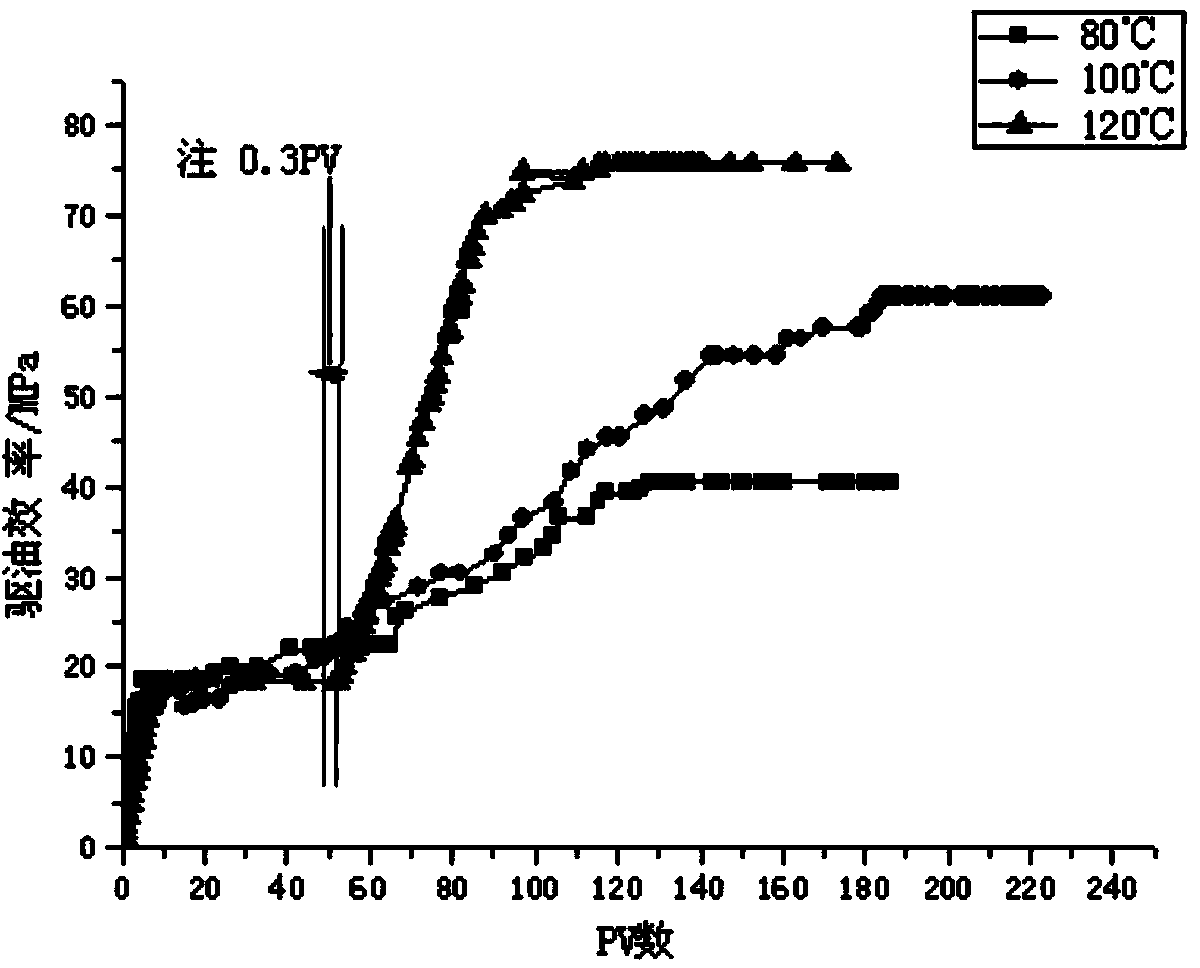

[0061] Apply the above treatment agent to the condensate gas reservoir and inject it into the core with an injection rate of 0.3PV.

Embodiment 2

[0062] Embodiment 2: long-acting mixed fluorocarbon surfactant treatment agent, raw material components are as follows by mass percentage:

[0063] Nonionic Fluorocarbon Surfactant CF 3 (CF 2 ) 7 (CH 2 CH 2 O) 15 H0.15%, zwitterionic fluorocarbon surfactant FSK0.1%, non-ionic hydrocarbon surfactant Pingping plus O-200.1%, methanol 20%, and the rest is water.

[0064] Apply the above-mentioned treatment agent to the condensate gas reservoir to inject the core, and the injection volume is 0.3PV.

Embodiment 3

[0065] Embodiment 3: long-acting mixed fluorocarbon surfactant treatment agent, raw material components are as follows by mass percentage:

[0066] Nonionic Fluorocarbon Surfactant CF 3 (CF 2 ) 7 (CH 2 CH 2 O) 20 H0.1%, zwitterionic fluorocarbon surfactant (DF-921) 0.15%, non-ionic hydrocarbon surfactant OP-200.2%, ethylene glycol 25%, and the rest is water.

[0067] The above-mentioned treatment agent is applied to the condensate gas reservoir to inject the core, and the injection volume is 0.2-0.3PV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com