A kind of yellow paste printed on silver cardboard or silver laser transfer paper and preparation method thereof

A technology of laser transfer paper and yellow paste, which is applied in the field of printing ink, can solve the problems of fluctuations in surface tension and affinity, affect the adhesion fastness of printing ink, and difficulty in controlling the white phase of barcodes, etc., and achieve good transparency and drying performance. Good surface color and gloss effect, strong printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

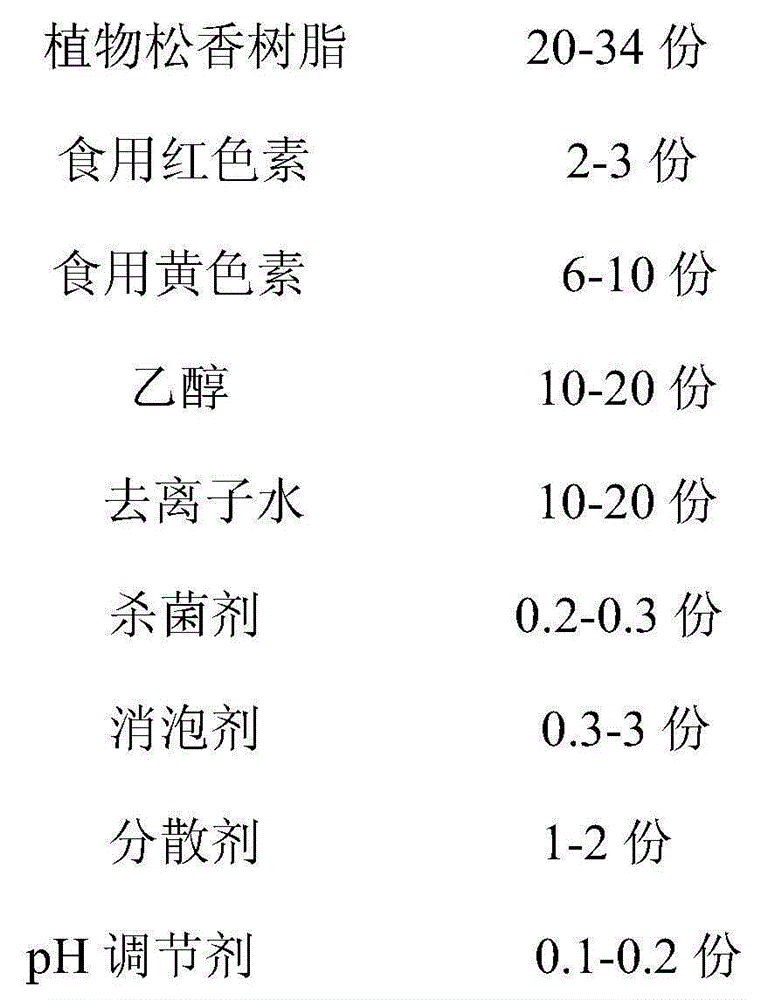

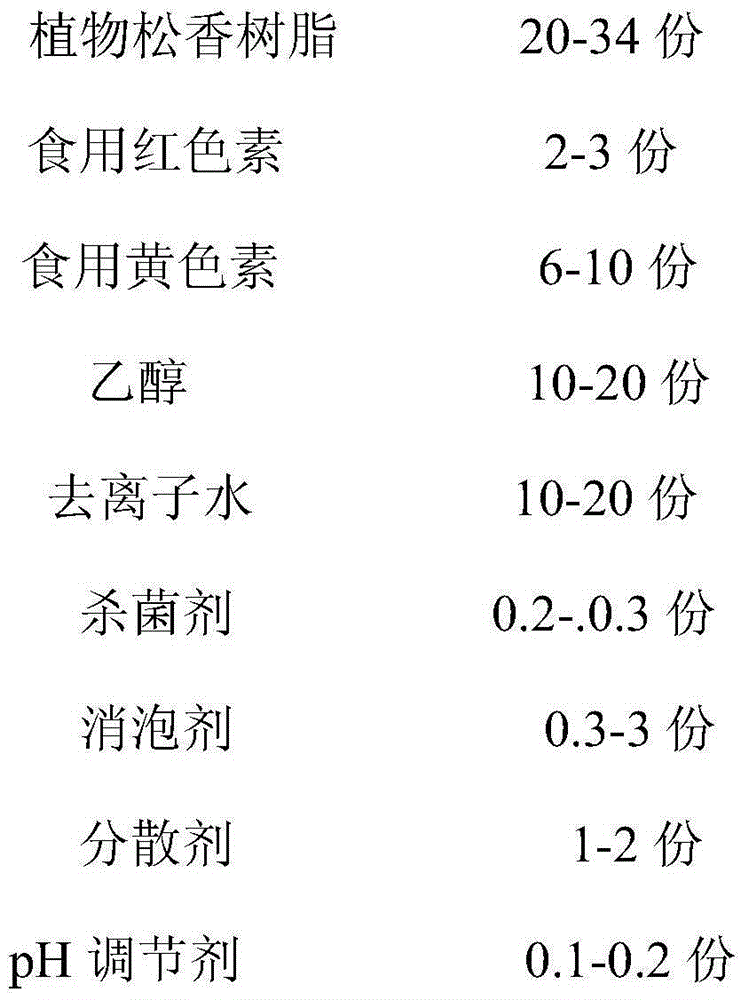

[0029] Embodiment 1: A preparation method of yellow paste printed on silver cardboard or silver laser transfer paper, consisting of the following parts by weight: 34 parts of plant rosin resin 138 of Zhengli Chemical Industry, 9 parts of tartrazine, 3 parts of Erythrosine, 2 parts of Lubrizol Dispersant 27000, 1 part of German TEGO defoamer 825, 20 parts of deionized water, 20 parts of ethanol with a concentration of 99.8%, 0.2 parts of ammonia solution with an ammonia content of 30-35%, 0.3 Sodium hypochlorite.

[0030] The specific preparation steps are as follows: put all the rosin resin 138 of Zhengli Chemical Industry into a container equipped with a high-speed disperser according to the above formula ratio, add all Lubrizol Dispersant 27000, one-third of the weight of deionized water and three Mix one part of the weight of ethanol evenly and disperse for 8-12 minutes under the condition of rotating speed of 800r / min, then add all German TEGO defoamer 825, erythrosine, ta...

Embodiment 2

[0031] Embodiment 2: A preparation method of yellow paste printed on silver cardboard or silver laser transfer paper, consisting of the following parts by weight: 28 parts of rosin resin 145 of Zhengli Chemical Industry, 2.5 parts of erythrosine, 7 parts Lemon yellow, 15 parts of ethanol with a concentration of 99.98% from Shanghai Liming Industry and Trade Co., Ltd., 15 parts of deionized water from Wuhan Xinke Deionized Water Company, 0.25 parts of hydrogen peroxide with a concentration of 20-25%, 2 parts of Dow Corning’s DC- 65, 1.5 parts of high molecular weight wetting and dispersing agent BYK-183, 0.15 parts of ammonia solution with 30-35% ammonia content;

[0032] The specific preparation steps are as follows: put all the rosin resin 145 of Zhengli Chemical Industry in a container equipped with a high-speed disperser according to the above formula ratio, add all the high molecular weight wetting and dispersing agent BYK-183, and one-third of the weight of deionized Mix ...

Embodiment 3

[0033] Example 3: A method for preparing yellow paste printed on silver cardboard or silver laser transfer paper, consisting of the following parts by weight: 20 parts of rosin resin 138 of Zhengli Chemical Industry, 6 parts of lemon yellow, 2 parts of red Moss, 1 part Lubrizol Dispersant 27000, 0.5 part German TEGO Antifoam 825, 10 parts deionized water, 10 parts ethanol at 99.8%, 0.2 parts sodium hypochlorite, 0.1 part 30-35% amine water .

[0034]The specific preparation steps are as follows: put all the rosin resin 138 of Zhengli Chemical Industry into a container equipped with a high-speed disperser according to the above formula ratio, add all Lubrizol Dispersant 27000, one-third of the weight of deionized water and three Mix one-tenth of the weight of ethanol evenly and disperse for 8-12 minutes at a speed of 800r / min, then add all the German TEGO defoamer 825, erythrosine, tartrazine, NW100 fungicide, ammonia content 30 35% ammonia solution, the remaining two-thirds o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com