Side suction nozzle packaging machine

A side suction nozzle and packaging machine technology, applied in packaging and other directions, can solve the problems of uneven sides of the side suction nozzle bag, low degree of automation, low production efficiency, etc., and achieve a shortened production cycle, high degree of automation, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

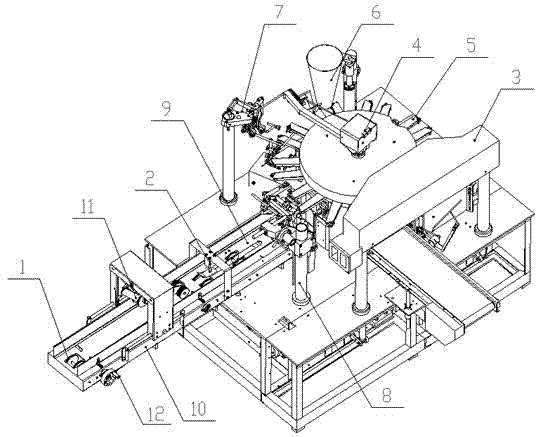

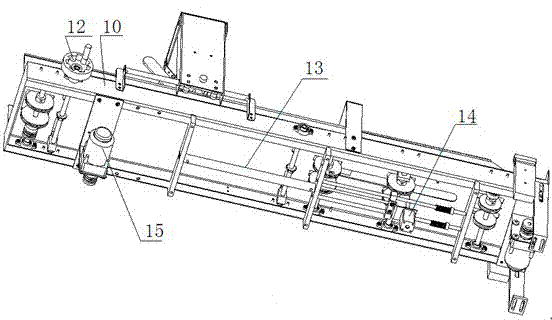

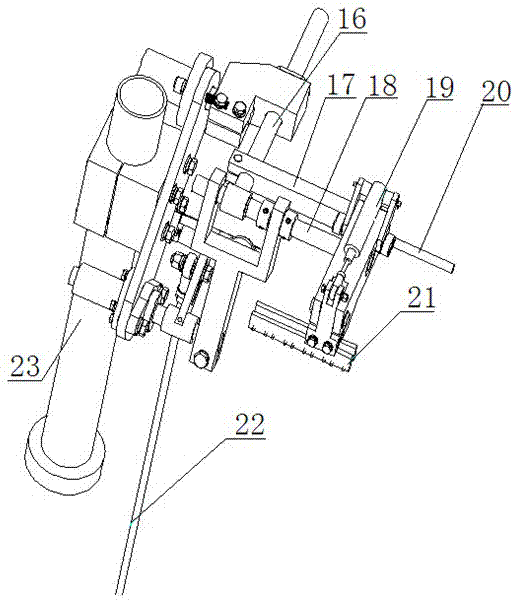

[0022] Reference Figure 1-Figure 3 , The side-suction nozzle packaging machine of this embodiment includes a side-suction nozzle horizontal bagging device 9, a bag opening fork device 4, a bag opening blowing device 7, a blanking device 6, a bag clamping device 5, a sealing device, and a flat bag The bag clamping device 8 and the rotating big tray, the side suction nozzle horizontal bag loading device 9, the flat bag clamping bag device 8 and the rotating big tray are arranged on the same straight line, the side suction nozzle horizontal bag up device 9 is installed on the horizontal bag support 10, the flat bag clamping device 8 is located at the right front of the side suction nozzle level upper bag device 9, and the rotating pan is located directly in front of the side suction nozzle level upper bag device 9. The bag opening fork device 4, the bag opening blowing device 7. The blanking device 6, the bag clamping device 5, and the sealing device are arranged on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com