Fiber enhanced rib-containing composite plate

A fiber-reinforced composite, fiber-reinforced technology, applied in the direction of hydraulic material layered products, layered products, chemical instruments and methods, etc., to achieve the effect of good bending and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

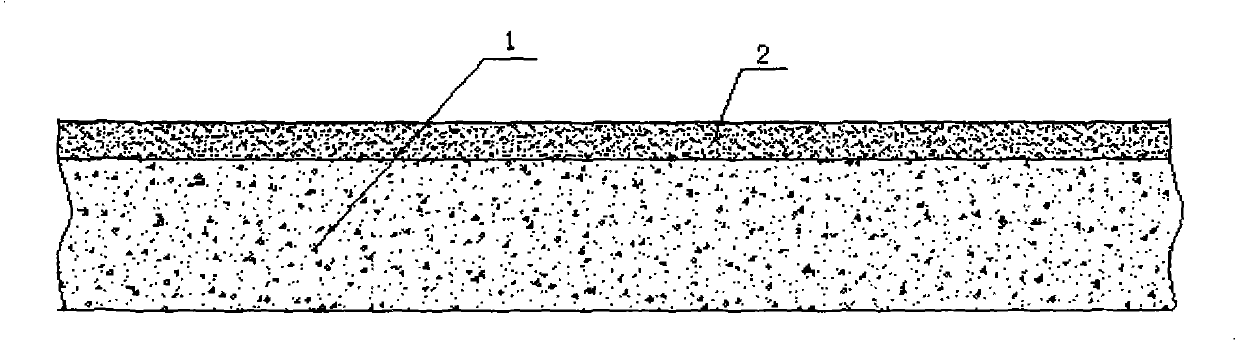

[0019] see figure 1 , in an embodiment of the present invention, a fiber-reinforced ribbed composite board includes a layer of primer layer 1 and a layer of fabric layer 2 laid on its upper surface. Both the bottom material layer and the fabric layer are laid by paste material, and the components of the paste material include quartz powder according to the weight ratio: cement: quicklime: paper fiber=40-60:15-25:15-25:5 -10; The specific ratio and thickness of each layer can be adjusted according to the requirements of the material. The fiber-reinforced composite plate with reinforcement includes fiber-reinforced composite calcium silicate board and fiber-reinforced composite cement board.

Embodiment 2

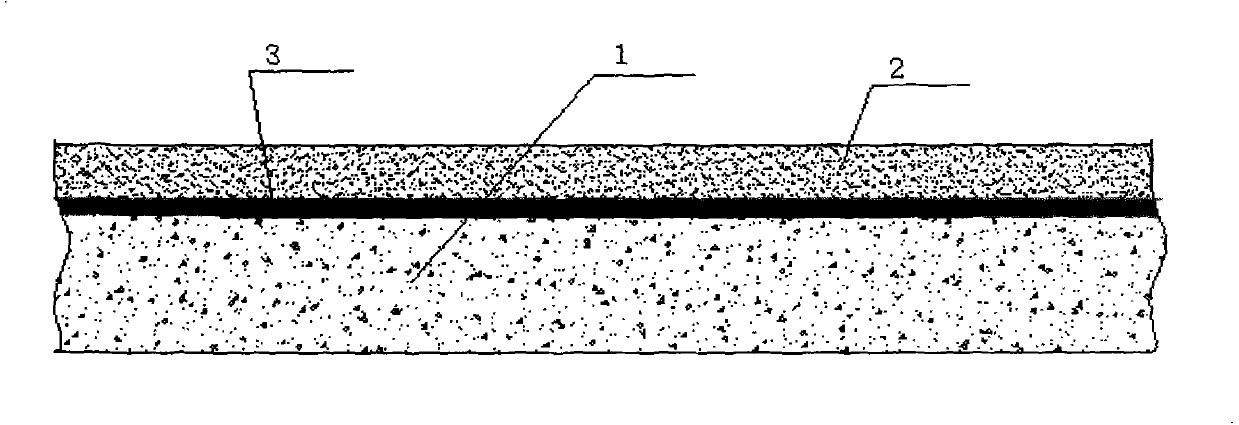

[0021] see figure 2 , in an embodiment of the present invention, a fiber-reinforced ribbed composite board comprises a layer of primer layer 1 and a layer of fabric layer 2, and a layer of reinforcement mesh layer 3 is laid between the primer layer 1 and the fabric layer 2. The reinforcement mesh layer 3 is a network or multi-strip structure made of metal or non-metal materials, which is used to enhance the bending and shearing strength of the board.

Embodiment 3

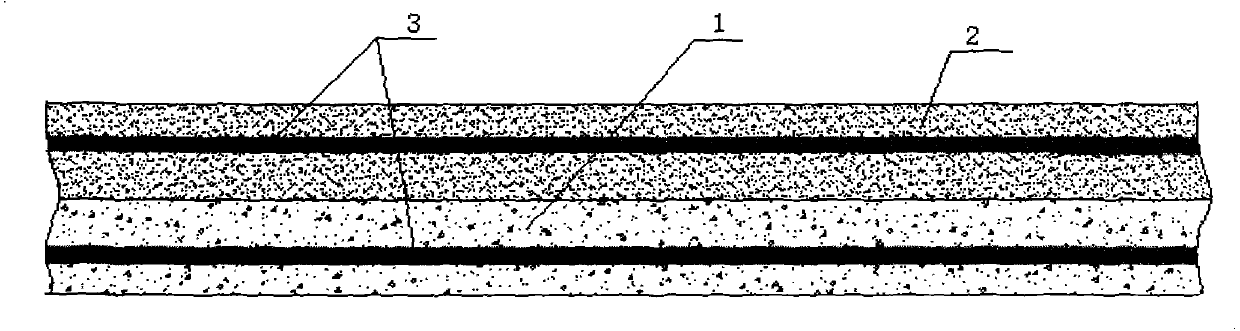

[0023] see image 3 , in the embodiment of the present invention, a kind of fiber-reinforced composite board with reinforcements, comprising two layers of bottom material layer 1 and two layers of fabric layer 2, a layer of reinforcement mesh is laid between the two layers of bottom material layer 1 and the two layers of fabric layer 2 Layer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com