Core-shell structure copper nanoparticle and preparation method thereof

A core-shell structure and copper nanotechnology, applied in the field of nanomaterials, can solve the problems of expensive Ag, easy oxidation of nano-copper particles, and unsuitability for large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

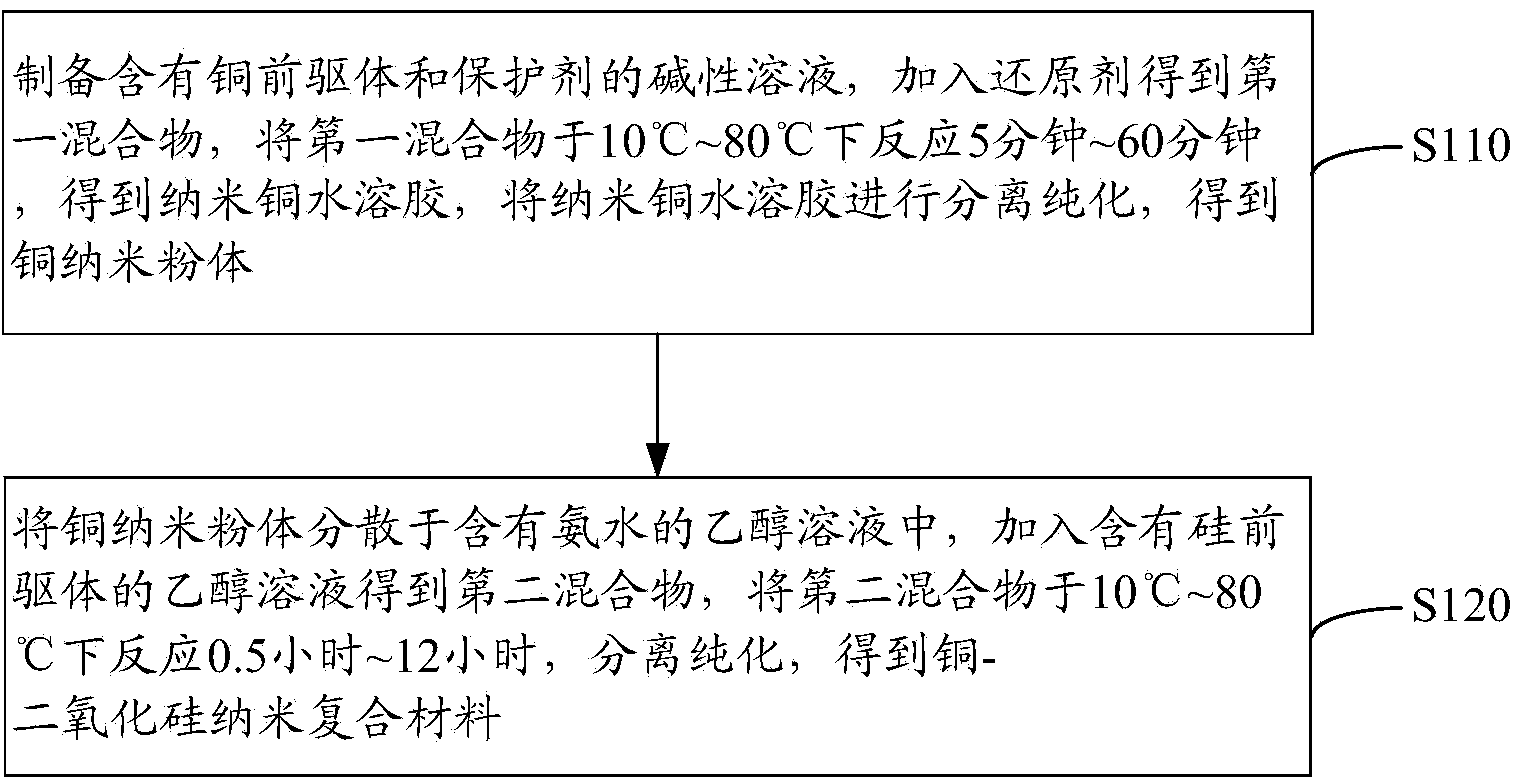

[0031] see figure 1 , a method for preparing copper nanoparticles with a core-shell structure includes the following steps S110 and S120.

[0032] Step S110: Prepare an alkaline solution containing a copper precursor and a protective agent, add a reducing agent to obtain a first mixture, and react the first mixture at 10°C to 80°C for 5 minutes to 60 minutes to obtain a nano-copper hydrosol. The copper hydrosol is separated and purified to obtain copper nanopowder.

[0033] The operation of preparing the alkaline solution containing copper precursor and protective agent is as follows:

[0034] The copper precursor and the protective agent are dissolved in a solvent, and an alkaline substance is added to obtain an alkaline solution containing the copper precursor and the protective agent. The solvent is preferably water.

[0035] The copper precursor is selected from at least one of copper sulfate, copper chloride, copper nitrate, copper acetate and copper hydroxide.

[003...

Embodiment 1

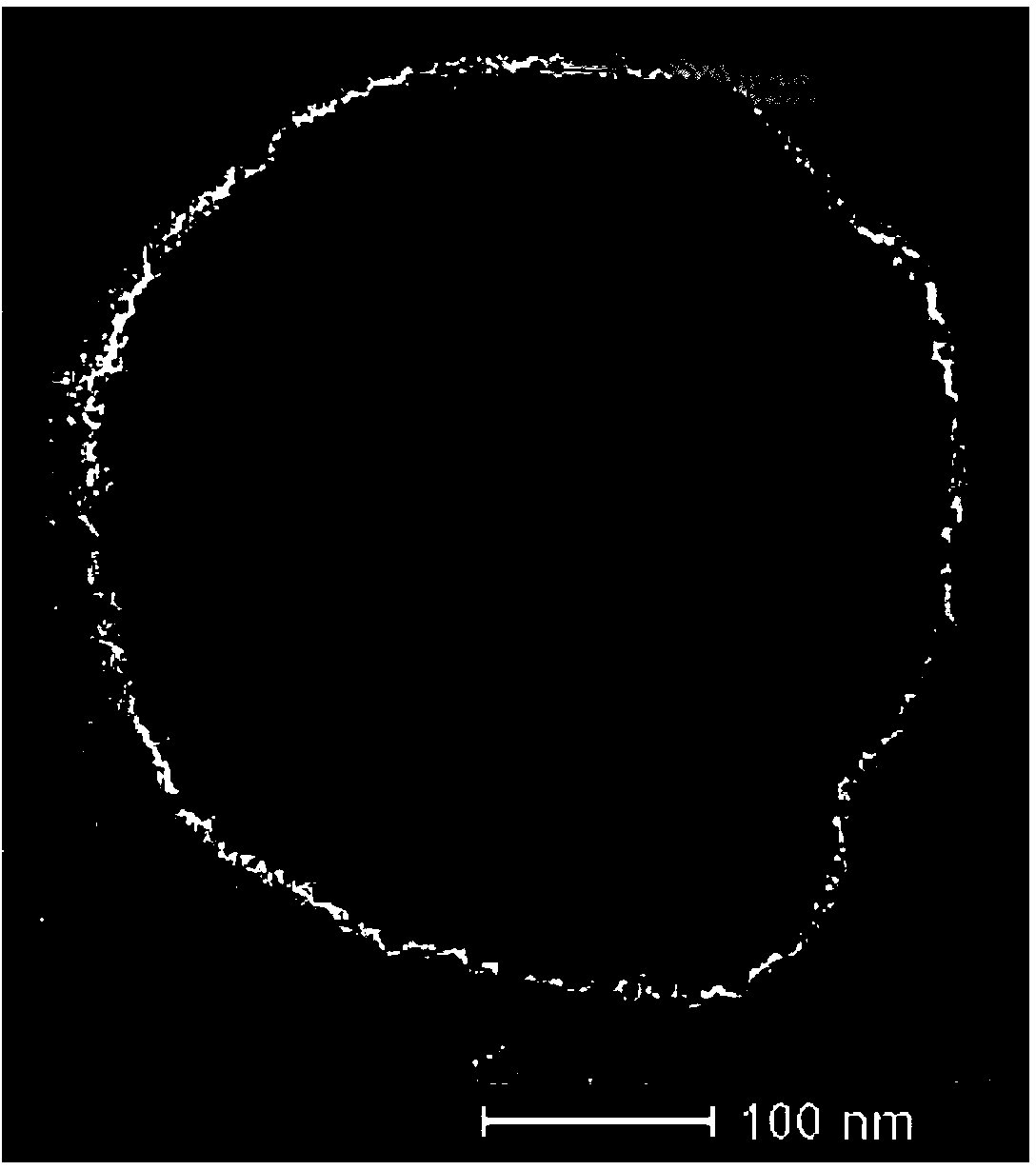

[0056] Into a 1000mL three-necked flask, add 300ml H 2 O, 10g Cu(OH) 2 , 10mLNH 3 ·H 2 O and 0.5g PVP to obtain an alkaline solution containing a copper precursor and a protective agent, then add 7mL mass fraction 80% hydrazine hydrate to obtain the first mixture, and react the first mixture at 50°C for 10min to obtain a brown-red nano-copper hydrosol , and then suction-filter, wash and dry the nano-copper hydrosol to obtain copper nano-powder. 5ml NH 3 ·H 2 O is added in the 200ml ethanol solution and is mixed with the ethanol solution that contains ammoniacal liquor, takes by weighing 6.6g copper nanopowder, is joined in the ethanol solution that contains ammoniacal liquor, then adds the 100ml ethanol solution that contains 20ml tetraethyl orthosilicate, The second mixture was obtained, and the second mixture was hydrolyzed and condensed at 50°C for 4 hours to obtain dark reddish-brown CuSiO 2 Hydrosol. The aqueous sol was suction filtered, washed, and vacuum-dried to...

Embodiment 2

[0060] Into a 1000mL three-necked flask, add 300ml H 2 O, 24.8g Cu(NO 3 ) 2 ·3H 2 O, 15mLNH 3 ·H 2 O and 0.5g PVP to get an alkaline solution containing copper precursor and protective agent, then add 3.88g NaBH 4 The first mixture was obtained, and the first mixture was reacted at 20° C. for 5 minutes to obtain a brown-red nano-copper hydrosol, and then the nano-copper hydrosol was suction-filtered, washed, and dried to obtain a copper nano-powder. 10mlNH 3 ·H 2 O was added to 200ml ethanol solution to prepare an ethanol solution containing ammonia, weighed 5g of nano-copper powder and added it to the ethanol solution containing ammonia, and then added 100ml ethanol solution containing 10ml γ-aminopropyltriethoxysilane , to obtain the second mixture, the second mixture was hydrolyzed and condensed at 60°C for 8h to obtain dark reddish brown CuSiO 2 Hydrosol. The aqueous sol was suction filtered, washed, and vacuum-dried to obtain CuSiO with a core-shell structure. 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com