Hierarchical porous chitosan/polylactic acid composite material and preparation method and application thereof

A hierarchical porous and composite material technology, applied in prosthetics, medical science, etc., can solve the problems of nutrients and metabolites hindering cell proliferation and tissue regeneration, so as to eliminate the risk of secondary surgery, promote adhesion and proliferation, The effect of rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

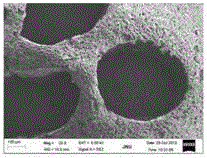

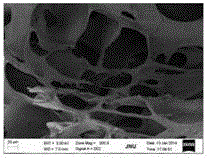

Image

Examples

Embodiment 1

[0050] A preparation method of hierarchical porous chitosan / polylactic acid composite material, comprising the following steps:

[0051] (1) Add 1 mL of sodium bicarbonate solution with a mass concentration of 5% to 4 mL of a chitosan solution with a mass concentration of 3% and mix to obtain a mixed solution, then pour the mixed solution into a mold, shake for 5 minutes, and let stand for 15 minutes , to obtain the primary material; then the primary material was stored at -80°C for 24h, freeze-dried at -70°C for 24h, neutralized with NaOH solution with a mass concentration of 5%, washed with distilled water, stored at -80°C for 24h and freeze-dried at -70°C for 24h, Obtain chitosan matrix scaffold;

[0052] (2) Soak the chitosan-based scaffold obtained in step (1) in polylactic acid / dichloromethane solution with a mass concentration of 3%, stir for 30min (500r / min), then let it stand for 6h, and finally place it at 35°C, -1atm vacuum drying for 12h to obtain the hierarchical...

Embodiment 2

[0059] A preparation method of hierarchical porous chitosan / polylactic acid composite material, comprising the following steps:

[0060] (1) Mix the sodium bicarbonate solution with a mass concentration of 10% and the chitosan solution with a mass concentration of 6% at a volume ratio of 1:5, stir at a speed of 500r / min for 3min to obtain a mixed solution, and then mix The solution was poured into the mold and left to stand for 10 minutes to obtain the primary material; then the primary material was stored at -80°C for 24 hours, freeze-dried at -70°C for 24 hours, neutralized with 5% NaOH solution, washed with distilled water, and stored at -80°C. 24h and freeze-drying at -70°C for 24h to obtain a chitosan matrix scaffold;

[0061](2) Soak the chitosan matrix scaffold obtained in step (1) in polylactic acid / dichloromethane solution with a mass concentration of 6%, stir for 45min (500r / min), then let it stand for 12h, and finally place it at 35°C, -1atm vacuum drying for 12h t...

Embodiment 3

[0068] A preparation method of hierarchical porous chitosan / polylactic acid composite material, comprising the following steps:

[0069] (1) Mix the sodium carbonate solution with a mass concentration of 8% and the chitosan solution with a mass concentration of 4% at a volume ratio of 1:5, stir at a speed of 500r / min for 3min to obtain a mixed solution, let it stand for 10min and then The mixed solution was poured into the mold to obtain the primary material; then the primary material was stored at -80°C for 24 hours, freeze-dried at -70°C for 24 hours, neutralized with 5% NaOH solution, washed with distilled water, and stored at -80°C for 24 hours and freeze-drying at -70°C for 24 hours to obtain a chitosan matrix scaffold;

[0070] (2) Soak the chitosan-based scaffold obtained in step (1) in a polylactic acid / methylene chloride solution with a mass concentration of 6%, stir at a speed of 500r / min for 30min, then let it stand for 6h, and finally place it at 35°C , -1atm vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com