Delay closing safety valve for electric pressure cooker

A technology of electric pressure cooker and safety valve, applied in pressure cooker and other directions, can solve the problems of affecting production efficiency, high cost efficiency, imperfect structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

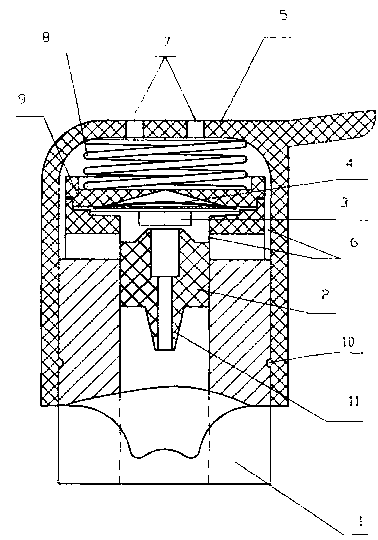

[0014] This example figure 1 As shown, the valve body 1 has a hole sleeved on the steam outlet pipe of the electric pressure cooker, and a closed seat 2 is arranged in the hole, and the closed seat 2 has a through hole, the outlet of the through hole is connected with the steam outlet 6, and the steam outlet 6 is connected with the outer cover 5 The steam outlet 7 on the top, the lower end of the closed seat 2 has a conical sealing nozzle 11, when the valve body 1 is sleeved on the exhaust pipe of the electric pressure cooker, the conical sealing nozzle 11 is inserted into the inner hole of the exhaust pipe of the original electric pressure cooker; The through hole outlet of 2 is provided with the gasket 3 driven by the temperature control sheet 4 to seal the through hole outlet of the sealing seat 2.

[0015] The top of the valve body 1 has a sunken circular hole, the lower end of the closed seat 2 is a circular boss, and the circular boss at the lower end of the closed seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com