Throttling component used for once-through steam generator

A technology of steam generator and throttling components, which is applied to the components of steam boilers, steam generation, steam boiler accessories, etc., can solve problems such as complex structure, and achieve the effect of simple structure and easy loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

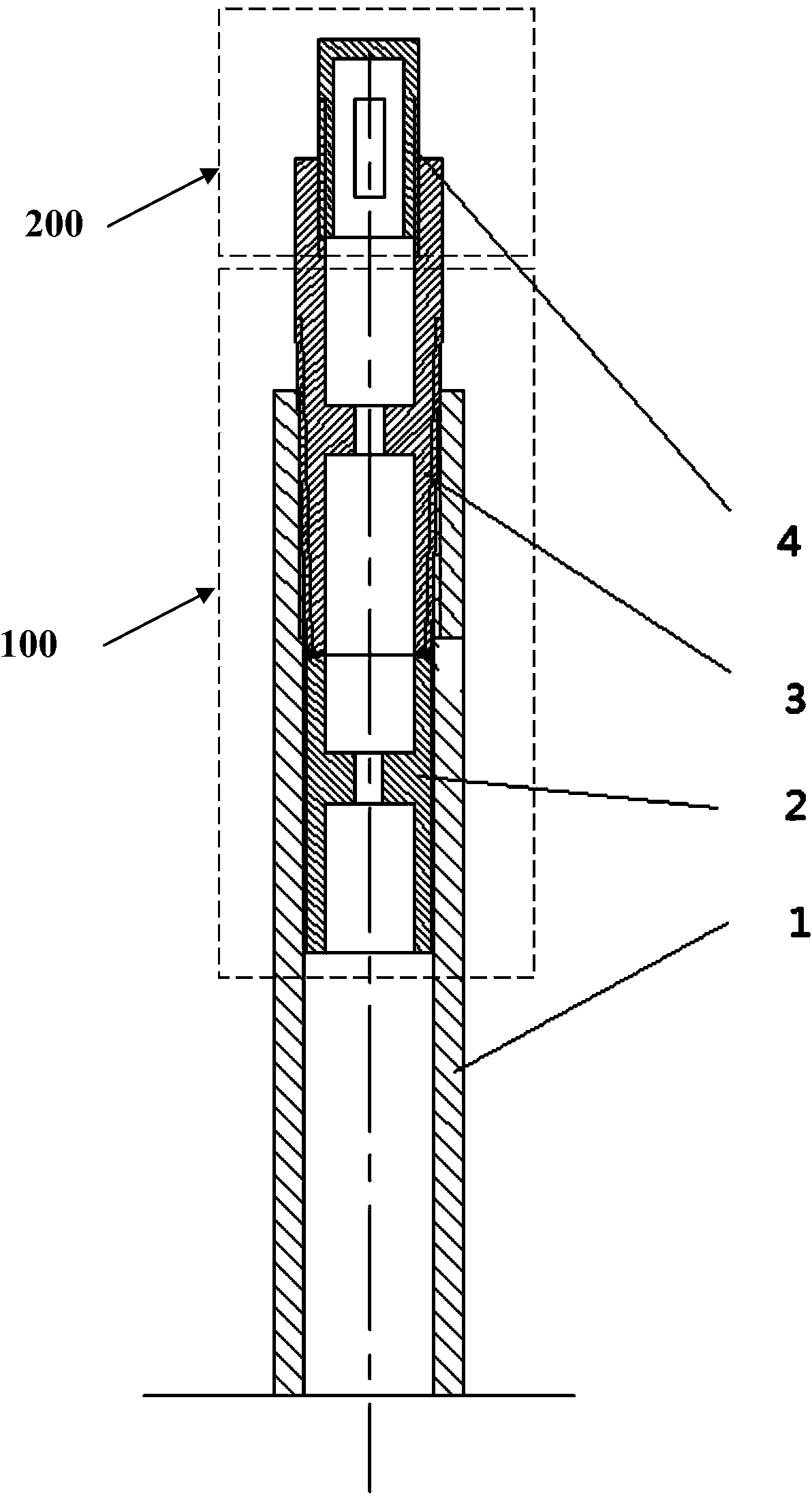

[0028] figure 1 It shows the first embodiment, a schematic diagram of a throttling assembly for a steam generator, which is arranged at the inlet end of the heat exchange tube of the steam generator, and is composed of two parts of the throttling assembly, which are high-strength and wear-resistant materials, wherein the first part of the throttling assembly 100 is a 2-stage throttling orifice (or a more-stage structure), and the second partial throttling assembly 200 is detachable, but the pressure drop is not adjustable. Referring to the figure, the throttling assembly of this embodiment mainly includes the following parts:

[0029] The first part of the throttling assembly 100 plays the role of limiting the flow in case of a broken pipe accident; this part of the throttling assembly is composed of a throttling orifice, and its throttling damping is a fixed value, and the fixed value is set as a stable damping; the stable damping refers to the damping that needs to be intro...

Embodiment 2

[0042] The components of this embodiment are basically the same as those of Embodiment 1. The only difference from Embodiment 1 is that the damping value of the second part of the throttling assembly 200 (the reference number is also 4) can be adjusted according to the actual situation, increasing the throttling Adaptability of stream components. This is also the preferred implementation mode. After plugging the tubes in this way, each heat exchange tube can be adjusted according to the actual situation of the evaporator heat exchange tubes, for example, including various factors such as manufacturing deviations such as tube inner diameters, diameter deviations of spiral tubes, and installation deviations. The pressure drop of the heat pipes is precisely adjusted to keep the temperature of the steam outlet of each heat exchange tube consistent, which is better than that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com