Large high temperature and high pressure rotary joint

A rotary joint, large-scale technology, used in drying solid materials, lighting and heating equipment, drying and other directions, can solve problems such as inability to adapt to large-scale production, unstable performance, and inability to match dryers, achieving compensation and buffering. The effect of good performance, long service life, simple installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the content of the present invention will be further described in conjunction with the accompanying drawings:

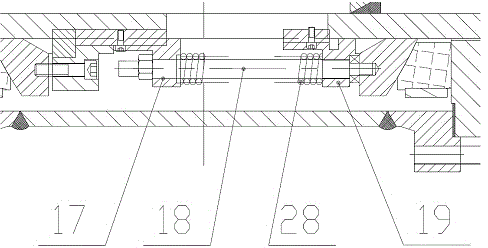

[0019] like Figure 1-2 As shown, a rotary joint for a large dryer is mainly composed of a graphite ring group 1, a gasket 2, a stationary ring 3, a transmission screw 4, a connecting flange 5, a transmission flange 6, a key 7, and a taper half ring 8 , steam shaft assembly 9, front bearing stuffing box 10, split half stop ring 11, spherical moving ring 12, wedge ring 13, outer cylinder 14, split half snap ring 15, transmission seat 16, spring seat 17, spring guide post 18. Push ring 19, rear bearing and sealing box 20, stuffing box 21, stuffing 22, spacer ring 23, stuffing gland 24, steam inlet pipe 25, condensate outlet pipe 26, graphite bushing 27, spring 28, graphite Ring outer hoop 29 forms. The steam shaft assembly 9 is a central jacketed pipe structure, which are steam channels and condensate channels respectively. The steam shaft assembly 9 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com