A kind of faucet structure of beer machine

A technology for faucets and beer machines, applied in the field of faucets, can solve problems affecting quality, easy to be oxidized, valve core corrosion, etc., and achieve the effect of convenient and thorough cleaning, not easy to corrode, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

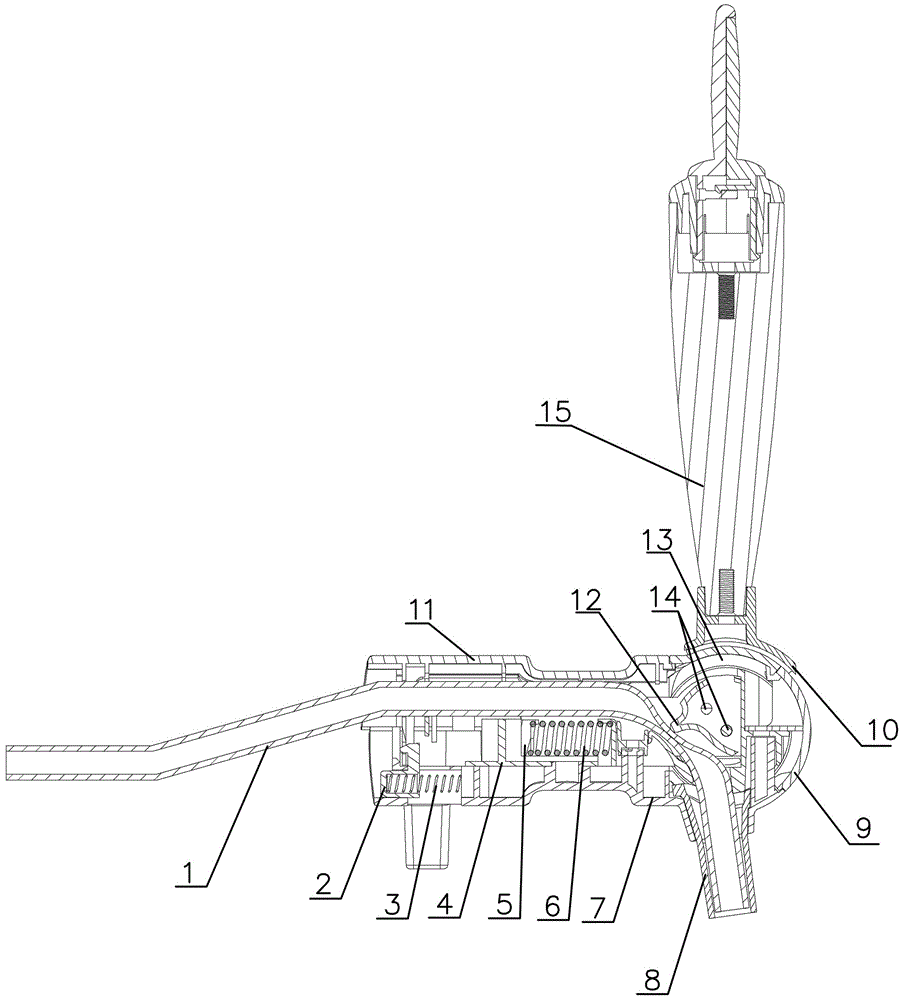

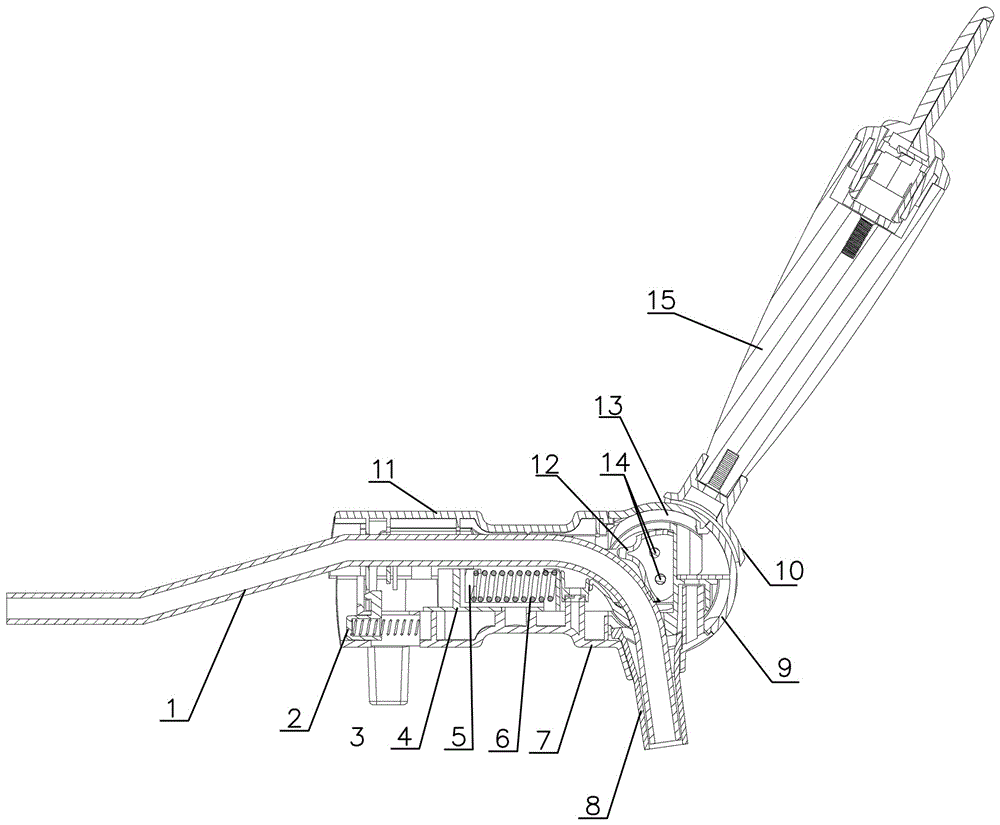

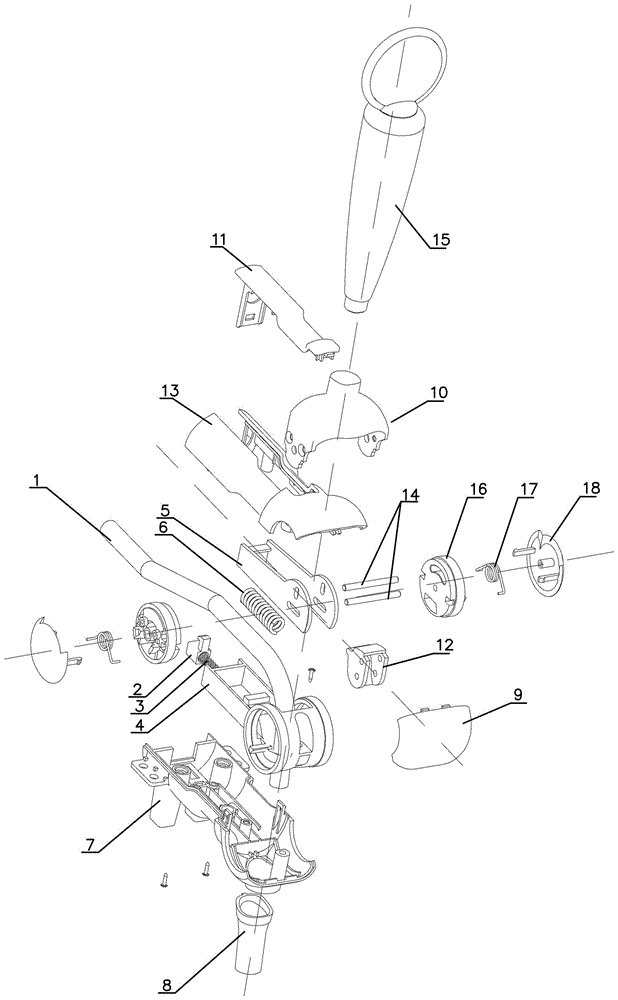

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as Figure 1~2 As shown, a beer machine faucet structure, the faucet structure includes a shell, a handle 15, a valve assembly, a hose 1,

[0017] There is a liquid outlet 8 on the shell;

[0018] The shell includes a bottom cover 7, an upper cover 13, a dismounting cover 11, and a front cover 9. The bottom cover 7 has a spring holder 2, and the disassembly cover 11 has a buckle matching the spring holder 2. The front end of the upper cover 13 is connected to the The front end of the bottom cover 7 is connected with buckles and hooks, the rear end of the upper cover 13 is pressed by the dismantling cover 11, and the buckle of the dismantling cover 11 is connected with the spring holder 2, and the front cover 9 is connected by the upper cover 13 and the bottom cover. 7 Press tight.

[0019] The valve assembly is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com